Anaconda Mining Reports Positive Phase I Open Pit Feasibility Study for the Goldboro Gold Project

Pre-tax Net Present Value (5%) of $484M with a pre-tax IRR of 31.2%

After-tax Net Present Value (5%) of $328M with an after-tax IRR of 25.5%

TORONTO, ON / ACCESSWIRE / December 16, 2021 / Anaconda Mining Inc. ("Anaconda" or the "Company") (TSX:ANX)(OTCQX:ANXGF) is pleased to report the results of the Phase I Open Pit Feasibility Study ("Feasibility Study" or the "Study") prepared in accordance with National Instrument 43-101 - Standards of Disclosure for Mineral Projects ("NI 43-101") for its 100% owned Goldboro Gold Project ("Goldboro", or the "Project") in Nova Scotia, Canada. All currency is presented in Canadian dollars (C$) and referenced as "C$" or "$", unless otherwise stated. Mineral Resources, Mineral Reserves, and the financial analysis for the Project were completed using base case assumptions of US$1,600 per ounce of gold and an exchange rate of US$1.00 to C$1.25.

Anaconda Mining welcomes investors and analysts to join President & CEO Kevin Bullock for a webinar hosted by Adelaide Capital today, December 16, 2021, at 2PM EST, to discuss the results of the Feasibility Study. Please see registration details below.

Highlights of the Feasibility Study

- Total gold recovered of over 1.10 million ounces over an approximately 11-year open pit life of mine ("LOM") with average gold production of 100,000 ounces per annum and an average diluted grade of 2.26 grams per tonne ("g/t") gold;

- Pre-tax Net Present Value at a 5% discount rate ("NPV 5%") of $484 million and a pre-tax Internal Rate of Return ("IRR") of 31.2%, with a projected pre-tax payback of 2.7 years;

- After-tax NPV 5% of $328 million and an after-tax IRR of 25.5%, projected after-tax payback of 2.9 years;

- Maiden Open Pit Probable Mineral Reserves of 1,150,200 ounces of gold (15.8 Mt at 2.26 g/t gold);

- Open pit Measured and Indicated Mineral Resources of 1,422,000 ounces (15.7 Mt at 2.82 g/t gold) and Underground Measured and Indicated Mineral resources of 1,159,000 ounces (5.9 Mt at 6.09 g/t gold);

- Open Pit Inferred Mineral Resources of 66,000 (0.98 Mt at 2.11 g/t gold) and Underground Inferred Mineral Resources of 418,000 ounces (2.2 Mt at 5.89 g/t gold);

- Initial capital cost ("Capex") of $271 million and LOM sustaining capital of $63.1 million;

- Life-of-Mine Operating Cash Costs of $966 (US$773) per ounce 1 and All-In Sustaining Costs ("AISC") of $1,062 (US$849) per ounce 1 ;

- Projected creation of approximately 345 direct full-time jobs during construction and 215 direct full-time jobs during operations, while generating in excess of $226 million in federal and provincial tax payments;

- Mill capacity of 4,000 tonnes per day ("tpd") based on a combined gravity and leaching circuit, yielding an average gold recovery of 95.8%; and

- At a gold price of $2,200 (~US$1,760), Goldboro could generate cumulative after-tax net cash flows of approximately $684 million, an after-tax NPV 5% of over $442 million and an after-tax IRR of 31.7%.

With Strong Opportunity for Further Value Creation

- Ongoing infill drilling has the potential to reduce the strip ratio and positively impact NPV and IRR by upgrading Inferred Mineral Resources coincident with the current open pit designs based on Measured and Indicated Mineral Resources only;

- Potential for Mineral Resource expansion, particularly towards the west with further exploration of a 1.5 kilometre long area along strike of the existing Goldboro Deposit ("Deposit") towards the past producing gold mine at Dolliver Mountain;

- The Goldboro Deposit has been drill tested to only 500 metres and remains open at depth. A future study will consider upgrading and expanding potentially mineable underground Mineral Resources as part of the longer-term mine development plan.

1 Refer to Non-IFRS Financial Measures below.

"Anaconda is extremely pleased to report its Phase 1 Open Pit Feasibility Study for the Goldboro Gold Project, encompassing the surface mining portion of the longer-term operating plan, which demonstrates almost 11 years of open pit mine life at an average annual gold production of 100,000 ounces. The Study demonstrates robust economics at a C$2,000 gold price (US$1,600) with an after-tax NPV 5% of $328 million, an after-tax IRR of 25.5% with a payback of 2.9 years, all in a top tier Canadian jurisdiction. The Project is expected to have significant social and economic impacts on the Municipality of the District of Guysborough with direct employment expected to reach 215 persons during operations and 345 during construction. The Project will contribute directly to Provincial and National economic growth by potentially generating over $226 million in taxes.

The Feasibility Study is a critical first step of our long-term development plan, which in the future will consider further technical studies to incorporate the high-grade underground mineral resource into the operation. Importantly, there continues to be tremendous upside potential at the Goldboro Deposit, which remains open in all directions. We believe near-term infill drill programs could further positively impact the value of the Project and the Company will be exploring along strike to the west of the Deposit towards the past producing Dolliver Mountain gold mine. We believe Goldboro has potential to be a long-life gold mine which can create significant value for our shareholders, Project rightsholders and stakeholders, including the Mi'kmaq of Nova Scotia and the Municipality of the District of Guysborough."

~ Kevin Bullock, President and CEO, Anaconda Mining Inc.

Investor and Analyst Webinar

Anaconda Mining welcomes investors and analysts to join President & CEO Kevin Bullock for a webinar today, December 16, 2021, at 2 PM EST, to discuss the results of the Feasibility Study. Please register at: https://us02web.zoom.us/webinar/register/WN_fbeTlLjcTLmfJ6CDMGZcfQ .The webinar will also be live-streamed on the Adelaide Capital YouTube channel here: https://www.youtube.com/channel/UC7Jpt_DWjF1qSCzfKlpLMWw . A replay will be made available afterwards.

Feasibility Study Overview and Next Steps

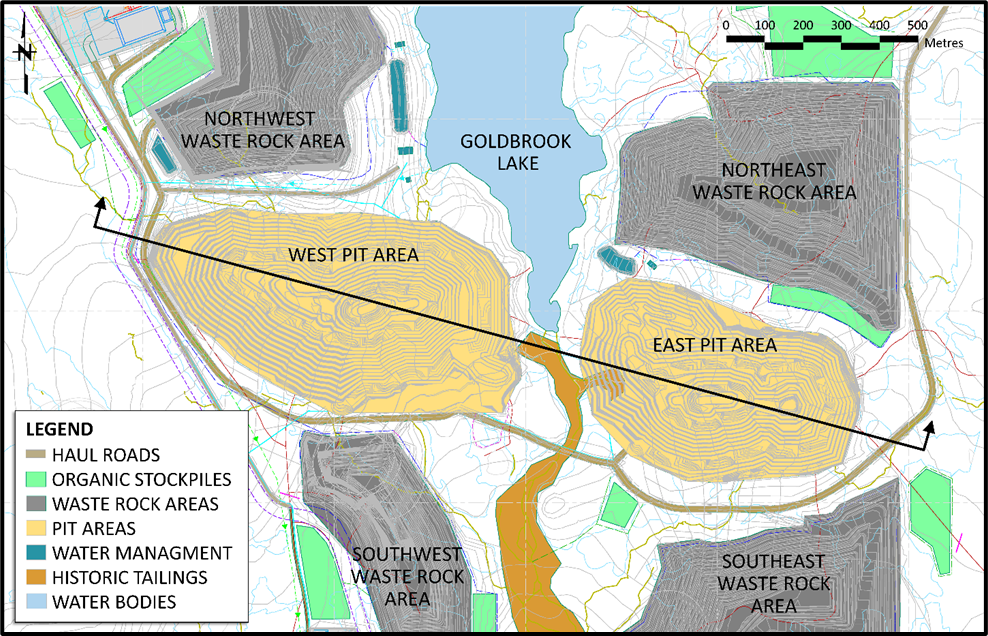

The results of the Phase 1 Feasibility Study for the Goldboro Gold Project demonstrate strong economics with a mine life of approximately 11 years and average annual gold production of 100,000 ounces. The open pit design in the Study contemplates two distinct open pits, a West Pit and East Pit, separated by Gold Brook Lake (see Figure 1 below). The Study outlines a conventional open pit mining operation and a 4,000 tpd processing facility based on a combined gravity and leaching circuit using carbon-in-pulp technology, achieving strong metallurgical recoveries of 95.8%. The Study represents Phase I of a longer-term mine development plan whereby, once open pit mining has commenced, the Company will consider further opportunities with respect to the underground Mineral Resource. This may include infill and expansion drilling, possibly from drifts off benches within the open pits, allowing for more effective and less expensive diamond drilling. Pending positive results of that work, the Company would then initiate a study to consider incorporating an underground mining operation to the Project.

The Company continues to work on an Environmental Assessment Registration Document ("EARD"), which is expected to be filed in Q2 2022. Throughout 2022, the Company will continue work to support Environmental Assessment and permitting activities, including Mi'kmaq engagement and public consultation, additional surface and groundwater modelling, detailed engineering, and ongoing baseline studies to support an Industrial Approval.

Importantly, the Goldboro Deposit continues to be open in all directions and the Company believes there is further potential to expand the Goldboro Deposit along strike and at depth. The Company is planning a 50 line-kilometre Induced Polarization geophysical survey over the area west and along strike of the Goldboro Deposit for approximately 1.5 kilometres up to the past-producing Dolliver Mountain gold mine, which will guide future exploration drilling.

The Goldboro Gold Project Feasibility Study

The Feasibility Study was completed by Nordmin Engineering Ltd. ("Nordmin") as Lead Mining and Geological Consultant. Ausenco Engineering Canada Inc. ("Ausenco") acted as Metallurgical and Processing Consultant, Knight Piésold Ltd. ("Knight Piésold") as Tailings Consultant, GHD Ltd. ("GHD") as Site Water Management and Environmental Consultant, Lorax Environmental Services Limited ("Lorax") as Geochemistry Consultant, and McCallum Environmental Ltd. ("McCallum") as Consultation and Permitting Consultant.

Table 1: Summary of Key Estimated Results and Assumptions in the Feasibility Study

| Production Data | Values | Units |

| Life of Mine | 10.9 | Years |

| Processing Rate | 4,000 / 1.46 | tpd / Mtpa |

| Recovered Gold | 1.1 | Moz |

| Average Gold Recovery | 95.8 | % |

| Pre-production Tonnes Mined | 4.1 | Mt |

| Total Material Mined (including pre-production) | 142.6 | Mt |

| Total Ore Tonnes Mined | 15.8 | Mt |

| Overall Strip Ratio | 8 | waste: ore |

| Total Tonnes Milled | 15.8 | Mt |

| Average Annual Gold Production | 100 | koz |

| Average Mill Feed Grade | 2.26 | g/t gold |

| Capital Costs | Values | Units |

| Initial Capital, Direct Cost Estimate | 193.9 | C$M |

| Initial Capital, Indirect Costs and Contingency | 77.1 | C$M |

| Total Initial Capital Costs | 271 | C$M |

| LOM Sustaining Capital Costs, including Indirect Costs and Contingency | 63.1 | C$M |

| Total Reclamation and Other Costs334.0pt334.0pt | 50.3 | C$M |

| Total LOM Capital Costs | 384.5 | C$M |

| NPV to Total Initial Capital Costs | 1.2 |

| Operating Costs | Values | Units |

| Open Pit Mining | 4.99 | C$/t mined |

| Processing | 13.45 | C$/t milled |

| Refining and Transport | 4.23 | C$/oz |

| Water Management and Treatment | 1.16 | C$/t milled |

| Site Support Costs | 8.7 | C$/t milled |

| Total Operating Cost | 67.05 | C$/t milled |

| Average Operating Cash Cost per Ounce 1 | 966 (US$773) | C$/oz |

| Average All-In Sustaining Cost per Ounce 1 | 1,062 (US$849) | C$/oz |

| Financial Analysis | Values | Units |

| Gold Price Assumption | $1,600 | US$/oz |

| Exchange Rate | 01:01.3 | US$:C$ |

| Gold Price Assumption | $2,000 | C$/oz |

| Pre-Tax Unlevered Free Cash Flow | 755 | C$M |

| Pre-Tax NPV 5% | 484 | C$M |

| Pre-Tax IRR | 31.2 | % |

| Pre-Tax Payback | 2.7 | years |

| After-Tax Unlevered Free Cash Flow | 529 | C$M |

| After-Tax NPV 5% | 328 | C$M |

| After-Tax IRR | 25.5 | % |

| After-Tax Payback | 2.9 | years |

| LOM Direct Income and Provincial Mining Taxes | 226 | C$M |

Notes:

- Refer to "Non-IFRS Financial Measures" below.

Mineral Resource Estimate

The Mineral Resource Estimate presented in Table 2 was prepared by Independent Qualified Person Glen Kuntz, P. Geo., of Nordmin. The Mineral Resource Estimate is based on validated results of 681 surface and underground drill holes for a total of 121,540 metres of diamond drilling completed between 1984 and the effective date of November 15, 2021, including 55,803 metres conducted by Anaconda.

Table 2: Mineral Resource Estimate for the Goldboro Gold Project - Effective Date November 15, 2021

Resource Type | Gold Cut-off (g/t gold) | Category | Tonnes | Grade (g/t gold) | Gold Troy Ounces |

| Open Pit | 0.45 | Measured | 7,680,000 | 2.76 | 681,000 |

Indicated | 7,988,000 | 2.89 | 741,000 | ||

Measured + Indicated | 15,668,000 | 2.82 | 1,422,000 | ||

Inferred | 975,000 | 2.11 | 66,000 | ||

| Underground | 2.40 | Measured | 1,576,000 | 7.45 | 377,000 |

Indicated | 4,350,000 | 5.59 | 782,000 | ||

Measured + Indicated | 5,925,000 | 6.09 | 1,159,000 | ||

Inferred | 2,206,000 | 5.89 | 418,000 | ||

| Combined Open Pit and Underground* | 0.45 and 2.40 | Measured | 9,255,000 | 3.56 | 1,058,000 |

Indicated | 12,338,000 | 3.84 | 1,523,000 | ||

Measured + Indicated | 21,593,000 | 3.72 | 2,581,000 | ||

Inferred | 3,181,000 | 4.73 | 484,000 |

* Combined Open Pit and Underground Mineral Resources; The Open Pit Mineral Resource is based on a 0.45 g/t gold cut-off grade, and the Underground Mineral Resource is based on 2.40 g/t gold cut-off grade.

Mineral Resource Estimate Notes

- Mineral Resources were prepared in accordance with NI 43-101 and the CIM Definition Standards for Mineral Resources and Mineral Reserves (2014) and the CIM Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines (2019). Mineral Resources that are not mineral reserves do not have demonstrated economic viability. This estimate of Mineral Resources may be materially affected by environmental, permitting, legal, title, taxation, sociopolitical, marketing, or other relevant issues.

- Mineral Resources are inclusive of Mineral Reserves.

- Open Pit Mineral Resources are reported at a cut-off grade of 0.45 g/t gold that is based on a gold price of C$2,000/oz (~US$1,600/oz) and a metallurgical recovery factor of 89% around cut-off as calculated from ((GRADE-(0.0262*LN(GRADE)+0.0712))/GRADE*100)-0.083.

- Underground Mineral Resource is reported at a cut-off grade of 2.60 g/t gold that is based on a gold price of C$2,000/oz (~US$1,600/oz) and a gold processing recovery factor of 97%.

- Assays were variably capped on a wireframe-by-wireframe basis.

- Specific gravity was applied using weighted averages to each individual wireframe.

- Effective date of the Mineral Resource Estimate is November 15, 2021.

- All figures are rounded to reflect the relative accuracy of the estimates and totals may not add correctly.

- Excludes unclassified mineralization located within mined out areas.

- Reported from within a mineralization envelope accounting for mineral continuity.

Mining and Mine Design

The Feasibility Study utilizes the Mineral Resource Estimate (see Table 2 ) that is conceptually mineable with open pit mining methods. Only portions of the Mineral Resource Estimate that fall within the constraints defined by the open pit parameters of the Study listed below (the "Mining Inventory") are used to inform the Study economics.

Economic limits for the two open pits were determined using Geovia's Whittle™ 4.7 software that uses the Lerchs-Grossmann ("LG") algorithm. The LG algorithm progressively identifies economic blocks, taking into account waste stripping, which results in a highest possible total value mined within the open pit shell subject to the specified pit slope constraints. The Pit Limit Analysis was performed on the Goldboro resource block model.

A 3D geological block model and other economic and operational variables were used as inputs into the LG algorithm. These variables include overall pit slope angle, mining costs, processing costs, selling costs, metal prices, and other variables. The economic parameters used for the pit limit analysis are listed in Table 3 .

Table 3: Pit Limit Analysis Parameters

Parameter | Value |

Currency Used for Evaluation | C$ |

Reblocked / Regularized Block Size | In-Situ model regularized to 2 m x 2 m x 4 m |

Overall Slope Angle | Rock: Varied by Sector - Range 42 o - 46 o |

Overburden: 25 o | |

Mining Cost | 0.8 Mining Cost Adjustment Factor (MCAF) for Overburden |

$5.10/t mined Rock | |

+ $0.016/t per 8 m | |

Process Cost, including milling, site support costs, tailings, rehabilitation | $25.75/t processed |

Selling Cost, including transportation of doré and refining costs | $5/oz |

% Payable | 99.95% |

Metal Price | US$1,600 per ounce of gold |

US$1: C$1.25 | |

C$2,000 per ounce of gold | |

Process Recovery | Based on Grade - Recovery Curve |

(GRADE-(0.0262*LN(GRADE)+0.0712))/GRADE*100-0.083 | |

Mining Loss & Dilution | Included within Re-blocked / Regularized Block Model Plus 5% factor for Mining Loss within optimization program Overall effect of ~26% additional tonnes and ~8% reduction in Metal |

Resources Used for Pit Shell Generation | Measured and Indicated |

Pit Shell Selection | Revenue Factor ("RF") 0.80 for Mine Planning |

Three boundary constraints were used in the pit limit analysis for the Goldboro Deposit:

- A 40 metre (X-Y) offset from the Natural Gas pipeline easement, on the west side of the property;

- A 50 metre (X-Y) offset from the edges of the Gold Brook Lake; and

- A 20 metre (X-Y) offset from the centerline of Gold Brook.

The block models were created in Datamine using 2 metre x 2 metre x 2 metre parent cell and variable sub-celling to 1 metre. For the open pit evaluation, the resource block model in Datamine format was reblocked to a regularized block model in Datamine format using Deswik.CAD. Default waste blocks and overburden blocks were added to the model. The envisioned selective mining excavator, at the onset of the analysis, will likely have a bucket width of approximately two metres. Mining is planned at an eight metre operating bench height.

To classify the material contained within the open pit limits as material for processing or material for waste, the milling cut-off grade is used. This break-even cut-off grade is calculated to cover the costs of processing, general and administrative costs, and selling costs using the economic and technical parameters listed in Table 3 . Mineral Resource material contained within the pit and above the cut-off grade is classified as potential mill feed ("PMF"), while resource material below the cut-off grade is classified as waste.

The cut-off grade has been estimated to be 0.45 g/t gold for the Open Pit. Table 4 provides the Mining Inventory for the Open Pits.

Table 4: Planned OP Mining Inventory - Tonnes and Grade by Category

Pit Area | Category | Diluted Tonnes | Diluted Grade (g/t gold) | Contained Gold (Troy ounces) |

West Pit | Probable Mineral Reserve | 10,331,000 | 2.12 | 704,000 |

Overburden | 5,196,000 | |||

Waste Rock | 73,681,000 | |||

Total Waste Rock | 78,877,000 | |||

Total Rock Mined | 89,208,000 | |||

East Pit | Probable Mineral Reserve | 5,468,000 | 2.54 | 446,000 |

Overburden | 3,061,000 | |||

Waste Rock | 44,813,000 | |||

Total Waste Rock | 47,874,000 | |||

Total Rock Mined | 53,342,000 |

Mine Operations

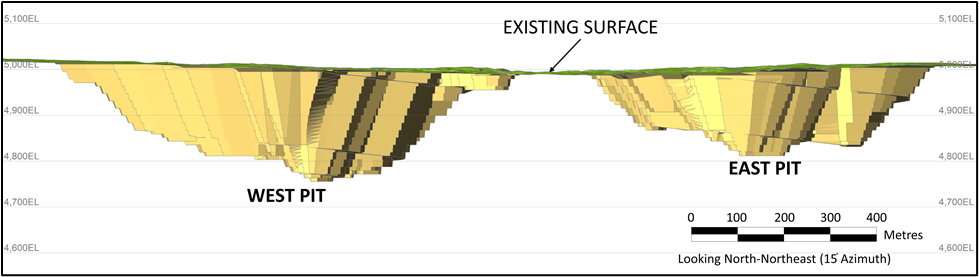

The operating scenario outlined in the Feasibility Study involves open pit mining at an average mining rate of 12.7 Mt per year and a gold processing plant with a capacity of 1.46 Mt per year (4,000 tpd). The Study contemplates a conventional truck-shovel open pit mining operation within two pits ( Figures 1 and 2 ). The open pit production period is approximately 11 years with one year of pre-production development. The open pit analysis results in two distinct open pits separated by Gold Brook Lake. The dimensions of the West Pit are approximately 1,025 metres long x 520 metres wide x 250 metres deep. The dimensions of the East Pit are approximately 775 metres long x 410 metres wide x 190 metres deep.

The Open Pit LOM plan proposes to mine approximately 15.8 Mt of PMF at a cut-off grade of 0.45 g/t gold, 8.3 Mt of overburden material and 118.5 Mt of waste rock material. The average stripping ratio is 8.0:1 waste tonnes to ore tonnes.

The Goldboro open pits were designed with the following preliminary assumptions:

- Nine (9) geotechnical sectors with bench face angles ranging from 70o to 85o, inter-ramp angles ranging from 49 o to 59 o ;

- Operational bench height of 8 metres and a final bench height of 16 metres;

- Berm width of 8.0 metres; and

- Ramp width of 25 metres, including 3x truck width (6.1 metres) for double lane traffic running surfaces, and allowances for safety berm and drainage ditch.

The Study open pit deign is outlined in Figures 1 and 2 below. The East Pit is currently planned to be developed in two stages, while the West Pit is planned to be developed in three phases. The East Pit would be completed in Year 8 of production and the West Pit is completed in Year 11 of production. Therefore, the East Pit will be available for the placement of waste rock from the West Pit, reducing haulage distances and related costs.

Figure 1: Goldboro Open Pit, Plan View

Figure 2: Goldboro Open Pit, Long Section View (looking North-Northeast)

The Study assumes contract mining will be used for the open pit mining activities. The main production fleet, although dependent on the Mining Contractor, is envisioned to consist of up to four drills (165 mm), one backhoe excavator (4.5 cubic metres), up to three hydraulic waste excavators (8 cubic metres), up to 14 haul trucks (90 tonne) and five (5) articulated haul trucks (40 tonne), up to four tracked dozers, one wheel dozer, and two graders.

Waste rock mined from the open pit is planned to be used for road and pad construction purposes and for the TMF embankment. When not used for those purposes, waste rock will be hauled and stored within four on-land waste rock storage areas and within the East Pit.

The presence of historical mining operation infrastructure, including several historical tailings sites associated with the past operation of the historical Boston Richardson Mine and location within the Gold Brook Lake-Seal Harbour Lake watershed are recognized as important environmental site factors. Based on available mapping, four areas of historic tailings were identified within the limits of planned Project infrastructure. A Historic Tailings Management Plan will be developed in consultation with Nova Scotia Environment and Climate Change (NSECC) to manage the areas that will be directly disturbed by the Project.

Mineral Reserve Estimate

The Mineral Reserve Estimate presented in Table 5 was prepared by Independent Qualified Person Joanne Robinson, P.Eng., of Nordmin.

Table 5: Mineral Reserve Statement for the Goldboro Gold Project - Effective Date of December 15, 2021

Category | Area | Cut-off Grade (g/t gold) | Tonnes (t) | Diluted Grade (g/t gold) | Contained Gold Metal (Troy ounces) |

Probable Mineral Reserve | East Pit | 0.45 g/t | 5,468,300 | 2.54 | 446,000 |

Probable Mineral Reserve | West Pit | 0.45 g/t | 10,330,600 | 2.12 | 704,200 |

Total | 0.45 g/t | 15,798,900 | 2.26 | 1,150,200 |

Mineral Reserve Estimate Notes

- Mineral Reserves were prepared in accordance with NI 43-101 and the CIM Definition Standards for Mineral Resources and Mineral Reserves (2014) and the CIM Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines (2019). This estimate of Mineral Reserves may be materially affected by environmental, permitting, legal, title, taxation, sociopolitical, marketing, or other relevant issues.

- The Effective Date of the Mineral Reserves Estimate is December 15, 2021.

- The Mineral Reserve Estimate is based metallurgical recovery algorithms which result in an overall average recovery of 95.8%.

- Metal prices are set at US$ 1,600/oz gold with an exchange rate assumption of 1US$:1.25C$ resulting in C$2,000/oz

- The Mineral Reserve was derived from a pit limit analysis and detailed pit design. A cut-off grade of 0.45 g/t gold was based on parameters described in Table 3.

- The Mineral Reserve Estimate incorporates mining dilution and mining loss assumptions through regularization of block size to 2mx2mx4m. An additional 5% mining loss assumption was incorporated. The overall impact is approximately 26% additional tonnes and approximately 8% reduction in contained gold.

Processing and Recovery

The process plant contemplated by the Study is expected to treat 1.46 Mt of potential mill feed per year at an average throughput rate of 4,000 tpd with a design availability of 92%. The process plant includes a three-stage crushing circuit, ball mill, gravity concentration and hydro-cyclone classification system, achieving a grind size of 100 µm. Ground ore is then treated by conventional cyanidation leach and carbon-in-pulp technology followed by cyanide destruction and arsenic precipitation before thickening and deposition into the Tailings Management Facility ("TMF").

The process plant design is similar to that outlined in the June 2021 Preliminary Economic Assessment ("PEA"). The previous carbon-in-leach technology has been modified to carbon-in-pulp, which is more suited to the leach kinetics and in turn will improve gold recovery. Additional minor refinements have also been made in the crusher sizing to provide additional operational flexibility, and in cyanide detoxification residence time to satisfy Metals and Diamond Effluent Regulations ("MDMER") regulatory levels for cyanide leaving the process plant. Process design has been supported by metallurgical testwork performed in 2020 and 2021 by Base Metallurgical Laboratories in Kamloops, BC ("Base Labs").

The process plant has been designed for an average gold recovery of 95.8% over the life of the project, an increase from the 95.2% open pit recovery estimated during the PEA. Of the 95.8% overall recovery, the gravity circuit is expected to recover an average of 40% of the gold delivered to the process plant, with the remaining 55.8% recovered through the leaching-adsorption-stripping circuit.

Capital and Operating Costs for Processing - Processing capital costs have a basis of estimate at Class 3 (FEL3) with a stated +/-15% accuracy and are stated in Q4 2021 Canadian dollars. Contingencies within the process capital costs are estimated on all capital items at an average 15%.

Growth factors of up to 4% have been applied on an input commodity by input commodity basis. More than 85% of equipment supply costs, bulk construction materials and contractor labour rates are estimated from quotes received from vendors/suppliers in Q3 and Q4 of 2021. The remaining 15% of costs are estimated from internal databases on recent Canadian gold projects.

Process-related costs over the life of mine, including pre-production, are estimated at $13.50 per tonne milled, and $13.45 per tonne milled over the operating period.

Capital and Operating Costs

Capital and operating cost estimates are stated in Canadian dollars and are estimated with an expected accuracy range of +/-15% weighted average accuracy of actual costs and were derived from various sources including consultant databases on analogous projects, indicative budget quotes, and from factoring.

The estimate of Initial Capital Costs is $271.0 million including indirect costs and contingency assumptions, as outlined in Table 6 below (note that columns may not sum exactly due to rounding). A contingency of $31.7 million has been included in the estimate of Initial Capital Costs, which amounts to approximately 16% of Direct Initial Capital Costs.

Sustaining capital, including rehabilitation and closure costs, fisheries and wetland compensation and the reversal of upfront working capital, is estimated at $106 million over the life of the mine. Details of the estimate are shown in Table 7 below (note that columns may not sum exactly due to rounding).

Table 6: Initial Capital Cost Estimate

| Cost Item / Description | Pre-Production Period C$ Million | % Of Total |

| Open Pit Mining, Pre-production Mining | 25.5 | 10 |

| Process Plant | 70.5 | 26 |

| Tailings Management | 20.6 | 7 |

| Site Development, Power, Electrical | 63 | 23 |

| Water Management and Treatment | 14.4 | 5 |

| Direct Initial Capital Estimate | 193.9 | 72 |

| Indirect Costs | 45.4 | 17 |

| Contingency | 31.7 | 12 |

| Total Capital Estimate | 271 | 100 |

Table 7: Sustaining Capital Cost Estimate

| Cost Item / Description | Production Period |

| C$ Million | |

| Open Pit Mining | 1.6 |

| Tailings Management (excludes closure) | 42.4 |

| Site Development | 7.4 |

| Water Management and Treatment | 11.7 |

| Subtotal Sustaining Capital Estimate | 63.1 |

| Mine Rehabilitation and Closure | 41 |

| Fisheries and Wetland Compensation | 9.3 |

| Total Estimate | 113.4 |

Operating Costs, detailed in Table 8 , are estimated at $67.05/t of material processed, which is composed of:

- Open pit mining costs of $43.74/t of open pit material processed, which includes stockpile rehandling (equivalent to $4.99 per tonne mined)

- Processing cost of $13.45/t processed

- Site Support costs of $8.70/t processed

- Water Treatment cost of $1.16/t processed

Table 8: Operating Cost Estimate

Cost Item / Description | Total C$ M | $/t mined | $/t milled | $/ounce gold |

Mining | 691.0 | 4.99 | 43.74 | 627 |

Processing | 212.5 | 13.45 | 193 | |

General and Administration | 137.5 | 8.70 | 125 | |

Water Treatment | 18.4 | 1.16 | 17 | |

Total Operating Costs | 1,060.0 | 67.05 | 961 | |

Note:

| ||||

Notable unit rates include $0.97/L for diesel, $0.102/kWh for electricity, and $0.70/L for propane.

Financial Analysis

The Study included an economic analysis which determined undiscounted and discounted net cash flows before and after tax. At a $2,000 price of gold per ounce (US$1,600 at a US$:C$ exchange of 1:1.25), the Project generates an after-tax NPV 5% of $328 million, an after-tax IRR of 25.5% and an after-tax payback on initial capital of 2.9 years. After-tax net free cash flow on an unlevered basis is estimated at $529 million.

On a pre-tax basis, the Project generates NPV 5% of $484 million, and IRR of 31.1%, and payback of 2.7 years. Pre-tax net cash flow for the Project is estimated at $755 million.

The gold price sensitivity on an after-tax basis is presented in Table 9 . Sensitivities to changes in other parameters are shown in Table 10 , on an after-tax basis.

Table 9: After-Tax Valuation Sensitivities to the Gold Price

Description | Unit | Net Present Value (C$ M) | |||||

% Variation | % | -20% | -10% | 0% | +10% | +20% | |

Au Price 2 | US$/oz | US$1,280 | US$1,440 | US$1,600 | US$1,760 | US$1,860 | |

C$/oz | C$1,600 | C$1,800 | C$2,000 | C$2,200 | C$1,920 | ||

Discount Rate | 0% | C$M | 219 | 274 | 529 | 684 | 839 |

3% | C$M | 140 | 269 | 398 | 526 | 654 | |

5% | C$M | 98 | 214 | 328 | 442 | 556 | |

8% | C$M | 47 | 146 | 243 | 340 | 437 | |

10% | C$M | 20 | 110 | 197 | 285 | 372 | |

IRR | % | 11.7% | 18.9% | 25.5% | 31.7% | 37.5% | |

Payback Period 3 | years | 6.1 | 4.7 | 2.9 | 2.5 | 2.2 | |

Table 10: After-Tax Valuation Sensitivity to Certain Parameters

Factor | 20% | 10% | 0% | -10% | -20% | |

Operating Cost | C$M | 1,271.2 | 1,165.3 | 1,060 | 953.4 | 847.5 |

IRR | 19.0% | 22.3% | 25.5% | 28.7% | 31.7% | |

NPV5% | 216 | 272 | 328 | 384 | 440 | |

Payback (yrs) 3 | 5.0 | 3.4 | 2.9 | 2.7 | 2.5 | |

Initial Capital Cost 4 | C$M | 325.3 | 298.2 | 271.1 | 244.9 | 216.8 |

IRR | 20.5% | 22.8% | 25.5% | 28.7% | 32.6% | |

NPV5% | 288 | 308 | 328 | 348 | 368 | |

Payback (yrs) 3 | 3.9 | 3.4 | 2.9 | 2.7 | 2.4 | |

Sustaining Capital Cost | C$M | 75.7 | 69.4 | 63.1 | 56.8 | 50.5 |

IRR | 24.8% | 25.2% | 25.5% | 25.9% | 26.3% | |

NPV5% | 315 | 321 | 328 | 335 | 342 | |

Payback (yrs) 3 | 3.0 | 3.0 | 2.9 | 2.9 | 2.9 | |

Notes for Table 9 and Table 10 :

- Refer to "Non-IFRS Financial Measures" below.

- Exchange rate of C$1.25:US$1 was used for the Canadian dollar gold price.

- Payback is defined as achieving cumulative positive free cashflow after all cash costs and capital costs, including sustaining capital costs and is counted from the start of production.

- Excludes initial working capital requirement s.

The Feasibility Study and the Goldboro Gold Project may be subject to legal, political, environmental or other risks that could materially affect the development of the Project which are unknown at this time but could materialize in the future.

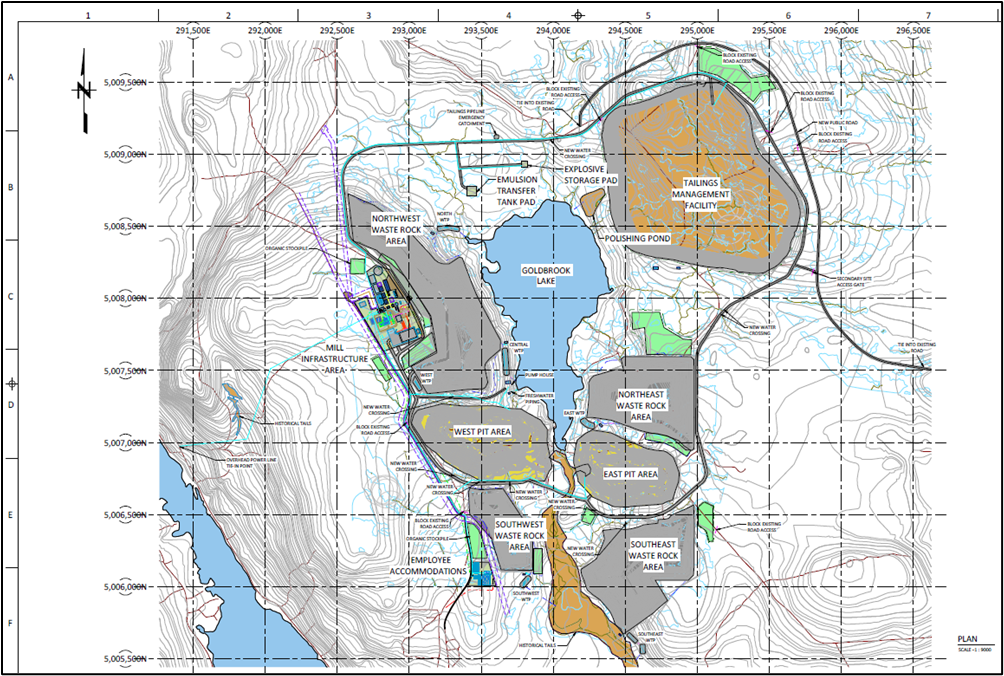

Infrastructure and Facilities

The main Project infrastructure components include mine and process plant supporting infrastructure, site accommodation facilities, TMF, external and internal access roads, power supply and distribution, freshwater supply and distribution, and a water treatment plant. The infrastructure for the feasibility study is situated within the locations shown in Figure 3 . It should be noted that the figure shows the maximum extents of the pit and various stockpiles and not a specific phase of the project.

Figure 3: General Site Plan (see Figure 1 for Legend)

The assumptions for mine and processing facilities included in the Study include the following:

- A truck shop / wash facility

- A process plant and laboratory

- Fuel storage facility

- Propane storage facility

- An explosive storage magazine

- Emulsion Transfer Tank

- Warehouse and laydown areas

- General Office Building

- Plant Office Building

- Mine Dry Building

- Core storage and a core yard

- ERT Facility

- Helipad

- Hazardous Waste Storage

- Employee Accommodations

- Water Treatment Facilities

- Main Switchyard

In total, approximately 5,300 m 2 of ancillary buildings (not including employee accommodations and process plant buildings) have been accounted for in the estimate of capital costs.

The main operational and support buildings are located on a prepared granular pad to the northwest of the West Pit, outside of the 500-metre buffer zone for blasting. This section of land slopes gently uphill to the west. The process plant, specifically the conveyor next to the Run of Mine ("ROM") stockpile are closest to the open pit. Further studies are required to determine the materials and method of construction that will be most cost-effective, efficient in construction, and appropriate to the local conditions.

The location of the new buildings and infrastructure areas were selected to maximize the use of the existing Goldbrook Road and other access roads on the mine site. As it is currently situated, Goldbrook Road will intercept the proposed open pit and will therefore need to be realigned and offset at least 30 metres from the open pits. Realignment of the road will require approximately 510 metres of deforestation, grading, and granular refilling. An estimated 2,900 metres of site roads will also be required in and around the mine site. In addition, an estimated 4,300 metres of public access roads will be required as the existing access road crosses the proposed TMF location. Clearing work is also included for an existing road, just east of Gold Brook Lake, to locate the explosives storage buildings.

With respect to communications, cellular service is currently available at the site, as is Wi-Fi, but will need to be extended to the office and process plant area. UHF radio will be used in the pits and TMF, with a base station at the guardhouse.

Power for the site is anticipated to be provided from a nearby Nova Scotia Power 25 kV distribution line installed along Highway 316. A 1.6 kilometre tap line would be installed along a new right of way to the mine site main substation. Nova Scotia Power would upgrade its existing distribution system as necessary to be able to provide the additional power required. Peak power demand for the site is estimated to be 10 MW, with the average demand estimated to be 7.5 MW. A network of 13.8 kV overhead distribution lines would be installed at site to provide power sourced from the main substation for the mine and surface infrastructure.

Tailings Management Facility (TMF)

The TMF will be constructed as a paddock style, single cell facility located on a side hill northeast of the proposed process plant. The TMF will contain 16.4 million tonnes of potentially acid generating ("PAG") tailings and 4.8 million tonnes of PAG1 waste rock. PAG1 waste rock has been identified as high-sulphur PAG and metal leaching ("ML"). A geomembrane lining system will be installed along the TMF basin floor and on the upstream face of the perimeter embankments to minimize seepage exiting the facility. The TMF development will include an initial starter embankment (Stage 1) followed by subsequent stages. Stages 2 through to 5 of the TMF will be expanded using downstream construction methods throughout the approximately 11-year mine life. The TMF embankments will be constructed using non-potentially acid generating ("PNAG") waste rock from open pit mining operations.

Both tailings and PAG1 waste rock will be managed by co-disposal in the TMF. Tailings and PAG1 waste rock would be transported to the TMF independently and placed in separate locations within the lined basin (i.e., co-placement). Following placement, the PAG1 waste rock will be inundated with ongoing thickened tailings slurry deposition and tailings supernatant water to maintain the materials in a saturated state. Maintaining the PAG1 material below the long-term phreatic surface within the TMF will prevent the onset of acid rock drainage ("ARD") conditions and help reduce ML from the PAG1 material.

Tailings will be pumped as a conventional thickened tailings slurry (typically 60% solids content by weight) from the process plant to the TMF via pipelines. Tailings will be deposited sub-aqueously (below the water surface) from the upstream face of the TMF embankments at multiple locations around the perimeter of the TMF basin and from the co-placed PAG1 waste rock in the central portion of the TMF. The tailings deposition strategy will allow for even filling of the basin to maintain a water cover over the tailings and maximize tailings storage within the impoundment.

Meteoric and supernatant inflows to the TMF basin will be temporarily stored prior to reclaim by a floating pump barge in the basin to the process plant. Water reclaim, treatment and release will be conducted so as to always maintain a minimum water cover of two (2) metres above the deposited tailings surface. Adequate freeboard allowances for temporary storage of the Environmental Design Storm ("EDS") have been included in the proposed staging plan. Based on the water balance, the TMF will operate in a net water surplus and excess water beyond the storage of the required water cover level and allowable operating range will be transferred to the TMF water treatment plant as required for treatment prior to release to the environment. The TMF will be equipped with an overflow spillway in each embankment stage to accommodate flows above the EDS and up to the Inflow Design Flood ("IDF").

For closure of the TMF, the water cover will be removed and a NAG rockfill cover with a surficial veneer of till and topsoil will be placed over the final TMF surface and revegetated

Water Management and Treatment

The Mine Water Management Plan and associated design measures were developed for the construction, operations and closure of the Project. All site contact water will be managed to meet the regulatory discharge requirements prior to discharge into the natural environment. The Mine Water Management Plan consists of a series of surface water ditches, culverts and settling ponds to collect stormwater runoff. Clean water ditching will direct non-contact water away from the site. Water Treatment units will be installed at the discharge of the TMF and waste rock storage areas where necessary. Surface water and groundwater monitoring programs will be implemented for all phases of the Project.

Environment, Permitting, Mi'kmaq Engagement and Public Consultation

The Goldboro Gold Project is subject to regulation under the Nova Scotia Environmental Act, Part IV. An Environmental Assessment Registration Document ("EARD") for the proposed project will be submitted for Class 1 Environmental Assessment in Q2 2022. The EARD will be authored by Anaconda and GHD, utilizing extensive baseline data collected at the Project site by Anaconda and its consultants since 2017, when Anaconda acquired the Project, augmented by ongoing studies which are outlined below.

Baseline scientific studies, combined with modelling efforts, shall inform project planning and provide the required information for various authorizations and permits. The following studies are in progress:

- Wetland delineation

- Archaeological resource impact assessment

- Mi'kmaq Ecological Knowledge Study ("MEKS")

- Aquatic biology and fisheries

- Aquatic effects

- Climate and hydrology

- Mine rock and water geochemistry

- Ground water and surface water modelling

- Water quality

- Air quality

- Noise and light

- Species at risk habitat suitability

- Human Health and Ecological Risk Assessment

- Phase I/II Environmental Site Assessment

- Country foods

- Wildlife

Anaconda shall also apply for a provincial Industrial Approval to Operate, planned for early 2023, and make applications for various permits associated with Mining and Crown Land access, mining, and milling permits, water use, watercourse/wetland alteration, and sewage treatment to support authorization for the construction and operation of the Project. Applications to federal authorities are also required, including but not limited to a Fisheries Act Authorization through Fisheries and Oceans Canada ("DFO") for alteration and destruction of fish habitat, as well as an amendment to Schedule 2 of the Metal and Diamond Mining Effluent Regulations associated with tailings placement. These applications will be made in early 2023, as regulations, and associated timelines dictate.

Anaconda recognizes the asserted Aboriginal & Treaty Rights and Title of Nova Scotia Mi'kmaq. The Company maintains an active information sharing relationship with Kwilmu'kw Maw-klusuaqn Negotiation Office ("KMKNO") and representatives of Paqtnkek Mi'kmaw Nation. On June 2, 2019, the Company and the Assembly of Nova Scotia Mi'kmaw Chiefs signed a Memorandum of Understanding ("MOU") that outlines a process that the parties may use to develop a Mutual Benefits Agreement ("MBA") that reflects a desire to build a mutually beneficial relationship with respect to the Project. This process is ongoing. Anaconda maintains its commitment to work collaboratively with Nova Scotia Mi'kmaq regarding environmental and cultural priorities, as well as social and economic opportunities throughout the life of the project. Information shared through ongoing Mi'kmaq engagement as well as completion of a Mi'kmaq Ecological Knowledge Study in 2017, has been reflected in the development of the project. A new MEKS is in progress that will reflect any new information or considerations related to the current footprint. The Company welcomes the opportunity to engage with any Mi'kmaw community's Council or organization that has an interest in the Project.

Public engagement has been ongoing with the Municipality of the District of Guysborough ("MODG"), as well as residents and property owners in the region since 2017. This includes regular meetings of Company senior executives and project consultants with the MODG Council. A Community Liaison Committee ("CLC") was established to foster environmental stewardship, and act as a conduit for transparent and ongoing communications between community, stakeholders, and Anaconda on all matters pertaining to potential development. Anaconda has held three open house meetings in Goldboro and will seek additional opportunities for community engagement prior to the submission of the EARD.

Technical Report and Qualified Persons

A Technical Report prepared in accordance with NI 43-101 for the Goldboro Gold Project Feasibility Study will be filed on SEDAR ( www.sedar.com ) before the end of January 2022. Readers are encouraged to read the Technical Report in its entirety, including all qualifications, assumptions and exclusions that relate to the Mineral Resource and Mineral Reserve and Feasibility Study. The Technical Report is intended to be read as a whole, and sections should not be read or relied upon out of context.

Kevin Bullock, P.Eng., President and Chief Executive Officer of Anaconda, and Paul McNeill, P. Geo., VP Exploration of Anaconda, are "Qualified Person(s)" as such term is defined under NI 43-101 and have each reviewed and approved the scientific and technical information and data included in this press release.

The Qualified Person responsible for the preparation of the Goldboro Gold Project Mineral Resource Estimate contained in this press release is Glen Kuntz, P. Geo. (Ontario, Nova Scotia) of Nordmin Engineering Ltd. The Qualified Person responsible for the preparation of the of the Goldboro Gold Project Mineral Reserve Estimate and mine plan contained in this press release is Joanne Robinson, P.Eng. of Nordmin Engineering Ltd. Tommaso Raponi, P.Eng., of Ausenco Engineering Canada Inc. is the Qualified Person responsible for processing and metallurgy. Timo Kirchner, P.Geo., of Lorax Environmental is the Qualified Person responsible for geochemistry. Steve Pumphrey, P.Eng. of Nordmin Engineering Ltd. is the Qualified Person responsible for Surface Infrastructure (excluding process plant). Reagan McIsaac, Ph.D., P.Eng., of Knight Piésold Ltd. is the Qualified Person responsible for design of the TMF and its water management infrastructure. Andrew Betts, P.Eng. (ON, Nova Scotia), of GHD is the Qualified Person responsible for surface water management.

Each of Mr. Kuntz, Ms. Robinson, Mr. Raponi, Mr. Kirchner, Mr. Pumphrey, Mr. McIsaac and Mr. Betts are considered to be an "Independent" of Anaconda and a "Qualified Person" under NI 43-101.

ABOUT ANACONDA

Anaconda Mining is a TSX and OTCQX-listed gold mining, development, and exploration company, focused in the top-tier Canadian mining jurisdictions of Newfoundland and Nova Scotia. The Company is advancing the Goldboro Gold Project in Nova Scotia, a significant growth project subject to a positive Feasibility Study with Mineral Reserves of 1.15 million ounces of gold (15.80 million tonnes at 2.26 g/t gold), Measured and Indicated Mineral Resources inclusive of Mineral Reserves of 2.58 million ounces (21.6 million tonnes at 3.72 g/t gold) and additional Inferred Mineral Resources of 0.48 million ounces (3.18 million tonnes at 4.73 g/t gold) (Please see above). Anaconda also operates mining and milling operations in the prolific Baie Verte Mining District of Newfoundland which includes the fully permitted Pine Cove Mill, tailings facility and deep-water port, as well as ~15,000 hectares of highly prospective mineral property, including those adjacent to the past producing, high-grade Nugget Pond Mine at its Tilt Cove Gold Project.

NON-IFRS MEASURES

Anaconda has included certain non-IFRS performance measures as detailed below. In the gold mining industry, these are common performance measures but may not be comparable to similar measures presented by other issuers. The Company believes that, in addition to conventional measures prepared in accordance with IFRS, certain investors use this information to evaluate the Company's performance and ability to generate cash flow. Accordingly, it is intended to provide additional information and should not be considered in isolation or as a substitute for measures of performance prepared in accordance with IFRS.

Operating Cash Costs per Ounce of Gold - Anaconda calculates operating cash costs per ounce by dividing operating expenses, net of by-product revenue, by payable gold ounces. Operating expenses include mine site operating costs such as mining, processing and administration as well as selling costs and royalties, however, excludes depletion and depreciation and rehabilitation costs.

All-In Sustaining Costs per Ounce of Gold - Anaconda has adopted an all-in sustaining cost ("AISC") performance measure that reflects all of the expenditures that are required to produce an ounce of gold from current operations. The Company defines all-in sustaining costs as the sum of operating cash costs (per above), sustaining capital (capital required to maintain current operations at existing levels), sustaining exploration, and rehabilitation and reclamation costs. All-in sustaining costs excludes initial capital expenditures, financing costs, corporate general and administrative costs and salvage value, and taxes. AISC per Ounce is calculated as AISC divided by payable gold ounces.

FORWARD-LOOKING STATEMENTS

This news release contains "forward-looking information" within the meaning of applicable Canadian and United States securities legislation. Forward-looking information includes, but is not limited to, disclosure regarding the economics and project parameters presented in the Feasibility Study, including, without limitation, Mineral Resource and Mineral Reserve Estimates, IRR, operating cash costs, all-in sustaining costs, NPV and other costs and economic information, possible events, conditions or financial performance that is based on assumptions about future economic conditions and courses of action; the timing and costs of future development and exploration activities on the Company's projects; success of development and exploration activities; permitting time lines and requirements; time lines for further studies; planned exploration and development of properties and the results thereof; and planned expenditures and budgets and the execution thereof. Generally, forward-looking information can be identified by the use of forward-looking terminology such as "plans", "expects", or "does not expect", "is expected", "budget", "scheduled", "estimates", "forecasts", "intends", "anticipates", or "does not anticipate", or "believes" or variations of such words and phrases or state that certain actions, events or results "may", "could", "would", "might", or "will be taken", "occur", or "be achieved". Forward-looking information is based on the opinions and estimates of management at the date the information is made, and is based on a number of assumptions and is subject to known and unknown risks, uncertainties and other factors that may cause the actual results, level of activity, performance or achievements of Anaconda to be materially different from those expressed or implied by such forward-looking information, including the risks outlined in this news release, risks associated with the exploration, development and mining such as economic factors as they effect exploration, future commodity prices, risks related to pandemics, including COVID-19, changes in foreign exchange and interest rates, actual results of current production, development and exploration activities, government regulation, political or economic developments, environmental risks, permitting timelines, capital expenditures, operating or technical difficulties in connection with development activities, employee relations, the speculative nature of gold exploration and development, including the risks of diminishing quantities of grades of resources, contests over title to properties, and changes in project parameters as plans continue to be refined as well as those risk factors discussed in Anaconda's annual information form for the year ended December 31, 2020, available on www.sedar.com. Although Anaconda has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking information, there may be other factors that cause results not to be as anticipated, estimated or intended. There can be no assurance that such information will prove to be accurate, as actual results and future events could differ materially from those anticipated in such information. Accordingly, readers should not place undue reliance on forward-looking information. The Company does not undertake to update any forward-looking information, except in accordance with applicable securities laws.

FOR ADDITIONAL INFORMATION CONTACT:

Anaconda Mining Inc.

Kevin Bullock

President and CEO

(647) 388-1842

kbullock@anacondamining.com

Reseau ProMarket Inc.

Dany Cenac Robert

Investor Relations

(514) 722-2276 x456

Dany.Cenac-Robert@ReseauProMarket.com

SOURCE: Anaconda Mining Inc.

View source version on accesswire.com:

https://www.accesswire.com/677994/Anaconda-Mining-Reports-Positive-Phase-I-Open-Pit-Feasibility-Study-for-the-Goldboro-Gold-Project