Aton Reports up to 97.9% Gold Recovery From Initial Scoping Level Metallurgical Testwork at the Semna Prospect

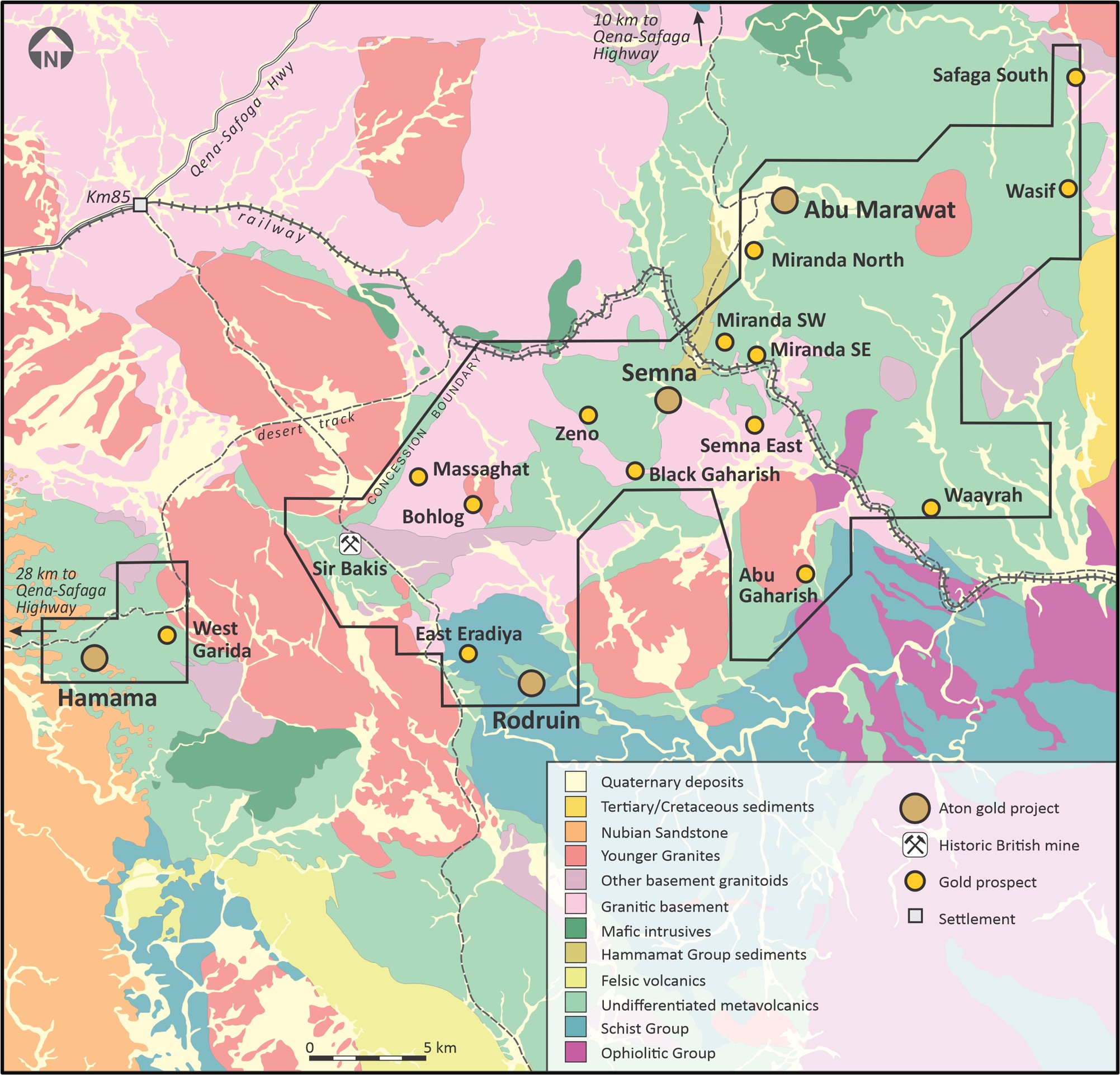

VANCOUVER, BC / ACCESSWIRE / January 4, 2024 / Aton Resources Inc. (TSXV:AAN) ("Aton" or the "Company") is pleased to update investors on the results of initial scoping level metallurgical testwork from its recent Semna drill discovery. Semna is located within the Company's 100% owned Abu Marawat Concession ("Abu Marawat" or the "Concession"), in the Eastern Desert of Egypt, see Figure 1.

Highlights:

- 2 composite metallurgical samples (SMMET-01 and SMMET-02), representative of mineralisation from the Main Vein zone at Semna, underwent scoping testwork. The 2 samples were selected and composited by Aton geologists from reverse circulation percussion ("RC") drill hole samples, and dispatched to Wardell Armstrong International Ltd ("WAI") in the UK for testing;

- The 2 composite samples were subjected to whole ore cyanide leach tests at a grind size of 80% passing 75µm. The leach test results showed final gold recoveries of 97.4% (SMMET-01) and 97.9% (SMMET-02), after 48 hours of leaching. Silver recoveries were 85.2% (SMMET-01) and 87.9% (SMMET-02);

- The 2 composite samples were also subjected to two-stage bulk gravity separation tests at grind sizes of 80% passing 212µm and 75µm. Gold and silver recoveries to the gravity concentrates were 56.4% and 38.0% respectively from sample SMMET-01, and 62.2% and 39.0% respectively from SMMET-02;

- Intensive cyanide leaching of the SMMET-01 gravity concentrate achieved gold and silver recoveries of 98.3% and 96.5% respectively, after 48 hours. Leaching of the SMMET-02 gravity concentrate achieved gold and silver recoveries of 98.6% and 97.3% respectively, after 48 hours;

- Separate cyanide leaching of the gravity tailings achieved gold and silver recoveries of 93.0% and 78.1% from the SMMET-01 sample after 48 hours, whilst gold and silver recoveries from the SMMET-02 sample were 93.6% and 87.5% after 48 hours;

- The combined gravity concentration + leach test results showed final gold recoveries of 96.0% (SMMET-01) and 96.7% (SMMET-02), after 48 hours of leaching. Silver recoveries were 85.1% (SMMET-01) and 91.3% (SMMET-02);

- Initial scoping tests indicates that the Semna Main Vein zone mineralisation is amenable to treatment by both conventional CIL, and gravity concentration-leach processing options.

"These initial scoping level metallurgical testwork results from Semna are exceedingly encouraging. The very high recoveries of both gold and silver indicate that the mineralisation that we have drilled to date in the Main Vein zone at Semna is readily amenable to treatment using both conventional CIL and gravity-leach process routes" said Tonno Vahk, Interim CEO. "This is very positive for us to be able to report these excellent metallurgical testwork results at such an early stage, and the new Semna discovery continues to look highly promising. Preparations for the phase 2 diamond drilling programme at Semna continue to advance rapidly, and we remain on track to start drilling later this month. We envisage the next phase of metallurgical testwork will be undertaken once we have drill core available for testing. We are also very close now to finalising the mining licence at Abu Marawat with the Egyptian Mineral Resources Authority and the Ministry of Petroleum and Mineral Resources, and we look forwards to being able to provide further updates on this very soon."

Metallurgical testwork programme

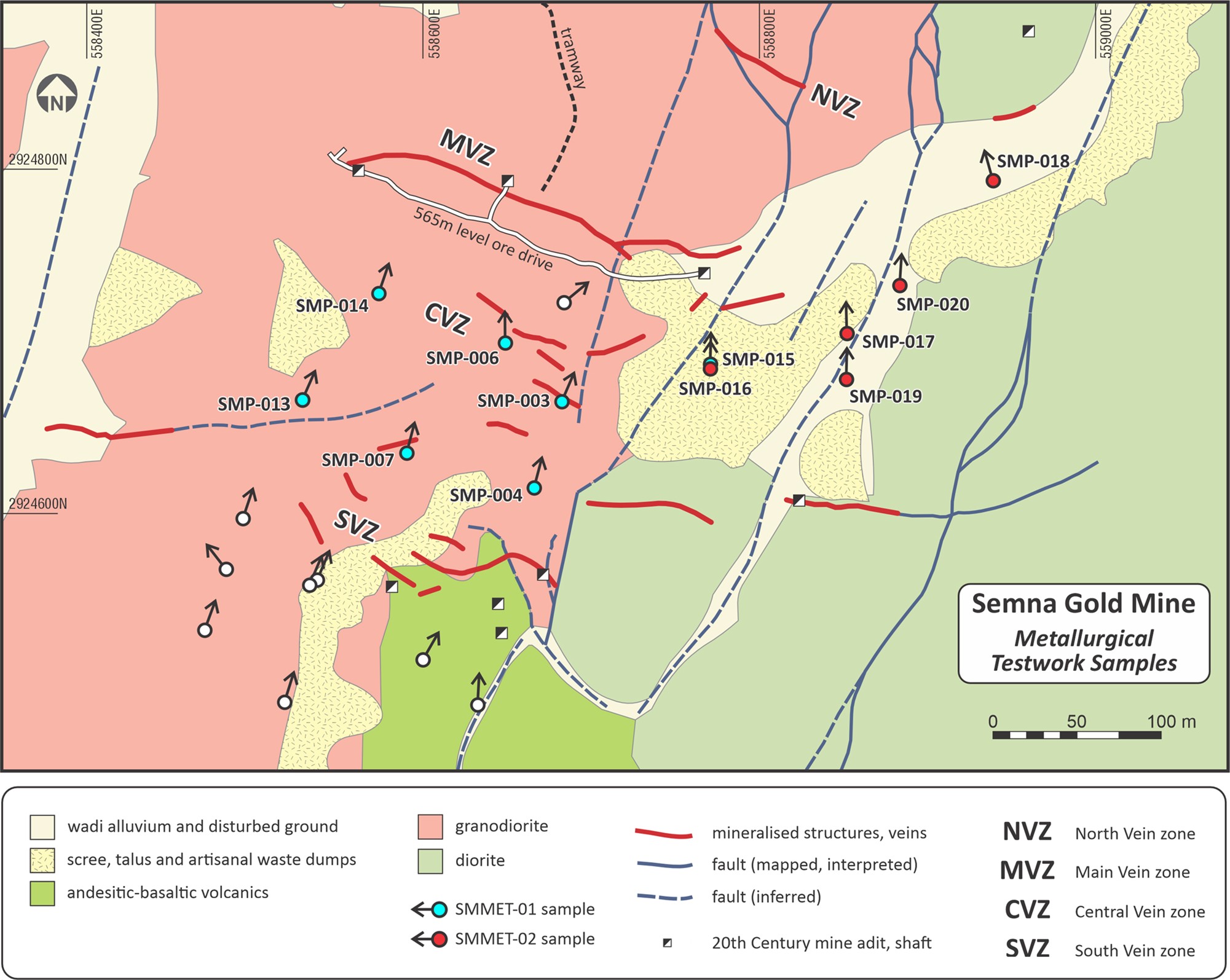

2 samples were prepared from RC drill samples for metallurgical testing, and were composited to represent the Main Vein zone ("MVZ") mineralisation at the Semna mineral deposit, as drilled to date. Samples were collected onsite from the bagged reject portion of the 1m sample splits from the phase 1 Semna RC drilling programme (see news release dated December 18, 2023). Both composite metallurgical samples weighed slightly less than 40kg. Details of the 2 composite samples are provided in Table 1, and the sampled drill hole collar locations are shown in Figure 2. The 2 composite samples were dispatched from Egypt to WAI's Truro laboratory in the United Kingdom, for a scoping level metallurgical testwork programme consisting of head assays, whole ore cyanide leach testing, gravity separation tests and cyanidation leaching of the gravity products.

The 2 metallurgical samples were composited from bulk reject material from the 1m sub-sample splits from the RC drilling programme, which were retained onsite at the Rodruin sample preparation facility (see news release dated December 18, 2023).

The SMMET-01 sample was composited from 26 separate 1m intervals from 7 different holes which intersected the western portion of the MVZ (see Figure 2), each weighing approximately 1.5kg. The individual grades of the 1m sub-samples varied between 0.40 g/t Au and 94.8 g/t Au, with the weighted average estimated grade of the composite sample being 9.75 g/t Au and 5.5 g/t Ag (Table 1). The individual 1m samples were taken from downhole depths of between 50-189m, and were composed of fresh sulphide mineralisation, displaying only occasional minor localised oxidation.

The SMMET-02 sample was composited from 39 separate 1m intervals from 5 different holes which intersected the eastern portion or extension of the MVZ (see Figure 2), each weighing approximately 1kg. The individual grades of the 1m sub-samples varied between 0.34 g/t Au and 51.8 g/t Au, with the weighted average estimated grade of the composite sample being 8.81 g/t Au and 3.8 g/t Ag (Table 1). The individual 1m samples were taken from downhole depths of between 56-141m, and were composed of fresh sulphide mineralisation, displaying only minor localised oxidation.

Composite sample ID | Total 1m samples | Weight (kg) | Original RC drill assay results (weighted average) | ||||

Au (g/t) | Ag (g/t) | Cu (ppm) | Pb (ppm) | Zn (ppm) | |||

SMMET-01 | 26 | 37.97 | 9.75 | 5.5 | 1844 | 7 | 50 |

SMMET-02 | 39 | 38.10 | 8.81 | 3.8 | 784 | 8 | 56 |

Table 1: Details of the composite metallurgical samples

Head assays

Head assays for gold, silver, copper, lead, zinc, arsenic, sulphur (total and sulphide) and carbon (total) were undertaken in-house by WAI using an aqua regia digest with an atomic absorption spectroscopy ("AAS") finish.

Separate sub-samples of the SMMET-01 and SMMET-02 composite samples were sent by WAI for additional head assay analyses by ALS Minerals. Gold and silver were analysed by metallic screen fire assay (ALS analytical code ME-SCR21). The samples were also analysed for a full multi-element suite of elements, and mercury, using a four acid digest followed by an ICP mass spectrometry finish (ALS analytical codes ME-MS61 and Hg-MS42), see Appendix A.

The results of the head assays are provided in Table 2. The screen fire assay analyses showed the SMMET-01 composite to grade 9.64 g/t Au and 8 g/t Ag, whilst the SMMET-02 composite was shown to grade 8.51 g/t Au and 6 g/t Ag.

Analyte | Units | WAI head assay results | Original RC drill assay results | |||

Composite sample ID | Composite sample ID | |||||

SMMET-01 | SMMET-02 | SMMET-01 | SMMET-02 | |||

Au | SFA 1 | g/t | 9.64 | 8.51 | 9.75 | 8.81 |

AR 2 | g/t | 9.01 | 7.58 | |||

Ag | SFA 1 | g/t | 8 | 6 | 5.5 | 3.8 |

AR 2 | g/t | 4.4 | 3.4 | |||

Cu 1 | % | 0.20 | 0.086 | 0.18 | 0.08 | |

Pb 1 | % | <0.001 | <0.001 | 0.001 | 0.001 | |

Zn 1 | % | 0.007 | 0.006 | 0.005 | 0.006 | |

As 1 | % | <0.001 | <0.001 | - | - | |

S(TOT) 1 | % | 2.46 | 1.50 | - | - | |

S(SUL) 1 | % | 2.39 | 1.44 | - | - | |

C(TOT) 1 | % | 1.04 | 1.96 | - | - | |

Notes:

| ||||||

Table 2: Head assay results

The screen fire gold assay results show good correlation with the original RC drill results (see Tables 1 and 2), and indicate that the c. 40kg bulk samples submitted for metallurgical testwork are representative of mineralised intervals sampled in the RC drill holes.

Separate to the assay results, the screen fire assay data also indicated that less than 10% of the gold and silver in both samples was distributed within the coarse (+100μm) fraction.

Base metal analyses showed both samples to be low in copper with 0.20% in the SMMET-01 composite and 0.086% in the SMMET-02 composite, whilst zinc grades were 0.007% and 0.006% respectively. Lead and arsenic were below the detection limit of 0.001% (Table 2). The multi-element ICP mass spectrometry analyses also indicated that the levels of deleterious elements including bismuth, cadmium, mercury and antimony were all very low, to a maximum of 2.54 ppm Bi in sample SMMET-02 (Appendix A).

Sulphur levels within the samples were 2.46% S(TOT) for the SMMET-01 composite and 1.50% S(TOT) for the SMMET-02 composite (Table 2), with the data showing that 96-97% of the sulphur was present in the sulphide phase. This data confirms the relatively low concentrations of sulphide minerals present in the MVZ mineralisation at Semna, and that the mineralisation is predominantly fresh, with only minor oxidation of the drilled mineralisation, as evidenced by the limited amount of iron and copper oxide minerals logged during the drilling.

Whole ore cyanide leach tests

A single whole ore cyanidation leach test was conducted on each of the composite samples at a grind size of 80% passing 75µm. The purpose of these tests was to investigate the amount of gold and silver that can be recovered from each sample by means of cyanide leaching.

Results are summarised in Table 3 below.

Composite sample ID | Residence time (hours) | Reagent consumption (kg/t) | Recovery (%) | |||

Lime | NaCN | Au | Ag | Cu | ||

SMMET-01 | 24 | 0.40 | 2.48 | 93.5 | 75.2 | 27.4 |

32 | 0.40 | 2.33 | 88.3 | 78.5 | 27.6 | |

48 | 0.40 | 2.55 | 97.4 | 85.2 | 29.1 | |

SMMET-02 | 24 | 0.36 | 2.26 | 100.0 | 85.9 | 23.1 |

32 | 0.36 | 2.00 | 99.7 | 86.8 | 23.2 | |

48 | 0.36 | 2.41 | 97.9 | 87.9 | 23.6 | |

Table 3: Whole ore cyanide leach test results

The test results showed that 93.5% of the gold in the SMMET-01 composite was recovered after 24 hours of leaching, increasing to 97.4% when the leach residence time was increased to 48 hours. Gold recovery from the SMMET-02 composite was 100.0% after 24 hours, reducing slightly to 97.9% after 48 hours.

75.2% of the silver in the SMMET-01 composite was recovered after 24 hours of leaching, increasing to 85.2% when the leach residence time was increased to 48 hours. Silver recovery from the SMMET-02 composite was 85.9% after 24 hours, increasing slightly to 87.9% after 48 hours.

Gravity + leach tests

Bulk gravity tests

Each composite was subjected to a programme of bulk gravity separation followed by cyanide leaching of the gravity products.

A 20kg sample of each composite was subjected to two stages of gravity processing using a Knelson KC-MD3 centrifugal gravity concentrator, with the first stage being conducted at a target grind size of 80% passing 212µm, and the second stage being conducted at a target grind size of 80% passing 75µm.

Results of the bulk gravity separation tests are shown in Table 4 below:

Composite sample ID | Product | Mass (%) | Assay (g/t) | Distribution (%) | ||||

Au | Ag | Cu | Au | Ag | Cu | |||

SMMET-01 | Concentrate | 1.03 | 448 | 182 | 8,100 | 56.4 | 38.0 | 4.5 |

Tailings | 98.97 | 3.63 | 3.1 | 1,800 | 43.6 | 62.0 | 95.5 | |

Feed | 100.00 | 8.22 | 5.0 | 1,865 | 100.0 | 100.0 | 100.0 | |

SMMET-02 | Concentrate | 1.00 | 489 | 136 | 4,700 | 62.2 | 39.0 | 5.7 |

Tailings | 99.00 | 3.01 | 2.2 | 785 | 37.8 | 61.0 | 94.3 | |

Feed | 100.00 | 7.88 | 3.5 | 824 | 100.0 | 100.0 | 100.0 | |

Table 4: Bulk gravity separation test results

The results showed that, after two stages of gravity separation, 56.4% of the gold and 38.0% of the silver had been recovered to the gravity concentrate for the SMMET-01 composite.

Gold and silver recoveries to the gravity concentrate for the SMMET-02 composite were 62.2% and 39.0% respectively.

In both cases approximately 1% of the total mass of the tested sample was recovered to the respective gravity concentrates.

Cyanide leaching of gravity concentrates

The gravity concentrates generated during the gravity separation stage were subjected to leach testing to evaluate the amount of gold and silver that could be recovered via intensive cyanidation leaching.

The intensive cyanidation leach tests were carried out for 48 hours with 20g/L sodium cyanide and 5g/L LeachWell™ GC.

Results of the gravity concentrate intensive cyanidation leach tests are shown in Table 5 below:

Composite sample ID | Residence time (hours) | Reagent consumption (kg/t) | Recovery (%) | |||

Lime | NaCN | Au | Ag | Cu | ||

SMMET-01 | 48 | 0.50 | 48.23 | 98.3 | 96.5 | 29.6 |

SMMET-02 | 48 | 0.11 | 50.87 | 98.6 | 97.3 | 32.7 |

Table 5: Gravity concentrate leach test results

Results for the SMMET-01 composite showed an overall gold recovery of 98.3% after 48 hours of leaching, with total extraction of the gold achieved after the first two hours of leaching. Results for the SMMET-02 composite showed an overall gold recovery of 98.6% after 48 hours of leaching, with 94.6% of the gold extracted within the first 2 hours of leaching.

Silver recoveries from the gravity concentrates after the 48 hours of leaching were 96.5% for the SMMET-01 composite and 97.3% for the SMMET-02 composite.

Cyanide leaching of gravity tailings

Separate to the leaching of the gravity concentrates, a representative sub-sample of the gravity tailings from each composite was subjected to cyanide leaching.

Results of the gravity tailings cyanidation leach tests are shown in Table 6 below:

Composite sample ID | Residence time (hours) | Reagent consumption (kg/t) | Recovery (%) | |||

Lime | NaCN | Au | Ag | Cu | ||

SMMET-01 | 48 | 0.13 | 2.33 | 93.0 | 78.1 | 25.5 |

SMMET-02 | 48 | 0.13 | 1.81 | 93.6 | 87.5 | 20.5 |

Table 6: Gravity tailings leach test results

Results showed overall gold recoveries after 48 hours of leaching of 93.0% for the SMMET-01 composite and 93.6% for the SMMET-02 composite, with silver recoveries of 78.1% and 87.5% respectively.

Combined Gravity + Leach Tests

Based on the results of the gravity and subsequent gravity product cyanide leach tests, cumulative metal recoveries for the gold, silver and copper have been calculated. The cumulative metal recoveries are shown in Appendix B.

The results in Appendix B show overall recoveries for the SMMET-01 composite using a combined gravity + leach methodology of 96.0% gold and 85.1% silver after 48 hours. Results for the SMMET-02 composite showed overall recoveries of 96.7% gold and 91.3% silver after 48 hours.

Whole ore leach versus gravity + leach tests

A summary of the comparative gold, silver and copper recoveries between the whole ore leach and gravity + leach test process routes are shown in Table 7.

Composite sample ID | Residence time (hours) | Recovery (%) | |||||

Whole ore leach | Gravity + leach | ||||||

Au | Ag | Cu | Au | Ag | Cu | ||

SMMET-01 | 24 | 93.5 | 75.2 | 27.4 | 96.3 | 84.8 | 24.5 |

48 | 97.4 | 85.2 | 29.1 | 96.0 | 85.1 | 25.7 | |

SMMET-02 | 24 | 100.0 | 85.9 | 23.1 | 95.5 | 89.8 | 20.3 |

48 | 97.9 | 87.9 | 23.6 | 96.7 | 91.3 | 21.2 | |

Table 7: Whole ore leach vs gravity + leach test results

Results in Table 7 show that the gold recoveries from both composite samples were marginally higher after 48 hours of leaching from the whole ore cyanidation leach test compared to the gravity + leach option. The silver recoveries from sample SMMET-01 were virtually identical from both the test routes, whereas from SMMET-02 silver recovery was lower after 48 hours of leaching from the whole ore cyanidation leach test compared to the gravity + leach option.

About Aton Resources Inc.

Aton Resources Inc. (AAN: TSX-V) is focused on its 100% owned Abu Marawat Concession ("Abu Marawat"), located in Egypt's Arabian-Nubian Shield, approximately 200 km north of Centamin's world-class Sukari gold mine. Aton has identified numerous gold and base metal exploration targets at Abu Marawat, including the Hamama deposit in the west, the Abu Marawat deposit in the northeast, and the advanced Rodruin exploration prospect in the south of the Concession. Two historic British gold mines are also located on the Concession at Sir Bakis and Semna. Aton has identified several distinct geological trends within Abu Marawat, which display potential for the development of a variety of styles of precious and base metal mineralisation. Abu Marawat is 447.7 km2 in size and is located in an area of excellent infrastructure; a four-lane highway, a 220kV power line, and a water pipeline are in close proximity, as are the international airports at Hurghada and Luxor.

Qualified person

The technical information contained in this News Release was prepared by Gary Patrick BSc, MAusIMM, CP (Met), Principal Consultant of Metallurg Pty Ltd. Mr. Patrick is a qualified person (QP) under National Instrument 43-101 Standards of Disclosure for Mineral Projects.

For further information regarding Aton Resources Inc., please visit us at www.atonresources.com or contact:

Tonno Vahk

Interim CEO

Tel: +1 345 525 2512

Email: info@atonresources.com

Note Regarding Forward-Looking Statements

Some of the statements contained in this release are forward-looking statements. Since forward-looking statements address future events and conditions; by their very nature they involve inherent risks and uncertainties. Actual results in each case could differ materially from those currently anticipated in such statements.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Appendix A - Multi-element analyses

Element | Unit | SMMET-01 | SMMET-02 | Element | Unit | SMMET-01 | SMMET-02 |

Ag | ppm | 4.33 | 4.11 | Na | % | 0.61 | 0.80 |

Al | % | 4.64 | 5.79 | Nb | ppm | 1.0 | 1.3 |

As | ppm | 34.4 | 25.7 | Ni | ppm | 24.9 | 22.8 |

Ba | ppm | 60 | 70 | P | ppm | 260 | 380 |

Be | ppm | 0.27 | 0.34 | Pb | ppm | 2.6 | 4.5 |

Bi | ppm | 2.52 | 2.54 | Rb | ppm | 21.0 | 25.1 |

Ca | % | 2.79 | 4.50 | Re | ppm | 0.004 | <0.002 |

Cd | ppm | 0.43 | 0.58 | S | % | 2.67 | 1.68 |

Ce | ppm | 3.79 | 6.15 | Sb | ppm | 1.25 | 1.64 |

Co | ppm | 27.0 | 26.7 | Sc | ppm | 17.7 | 22.6 |

Cr | ppm | 54 | 59 | Se | ppm | 2 | 2 |

Cs | ppm | 0.26 | 0.39 | Sn | ppm | 1.0 | 1.5 |

Cu | ppm | 1780 | 788 | Sr | ppm | 62.4 | 92.1 |

Fe | % | 5.65 | 5.75 | Ta | ppm | 0.28 | 0.08 |

Ga | ppm | 10.35 | 13.55 | Te | ppm | 1.09 | 1.24 |

Ge | ppm | 0.10 | 0.09 | Th | ppm | 0.15 | 0.21 |

Hf | ppm | 0.2 | 0.2 | Ti | % | 0.180 | 0.312 |

Hg 1 | ppm | 0.030 | 0.035 | Tl | ppm | 0.11 | 0.13 |

In | ppm | 0.426 | 0.156 | U | ppm | 0.1 | 0.2 |

K | % | 0.93 | 1.03 | V | ppm | 131 | 165 |

La | ppm | 1.6 | 2.6 | W | ppm | 6.5 | 7.8 |

Li | ppm | 8.3 | 11.8 | Y | ppm | 3.4 | 4.8 |

Mg | % | 0.79 | 1.38 | Zn | ppm | 56 | 71 |

Mn | ppm | 752 | 1095 | Zr | ppm | 4.5 | 5.9 |

Mo | ppm | 9.72 | 3.36 | - | - | - | - |

Notes:

| |||||||

Table A1: Multi-element head assay analyses

Appendix B - Combined gravity + leach test results

Composite sample ID | Gravity stage | Leach stage | Combined gravity + leach | ||||||||||||

Product name | Mass (%) | Distribution (%) | Reagent consumption (kg/t) | Recovery (%) | Reagent consumption (kg/t) | Recovery (%) | |||||||||

Au | Ag | Cu | Lime | NaCN | Au | Ag | Cu | Lime | NaCN | Au | Ag | Cu | |||

SMMET-01 | Concentrate | 1.03 | 56.4 | 38.0 | 4.5 | 0.50 | 48.23 | 98.3 | 96.5 | 29.6 | 0.01 | 0.50 | 55.4 | 36.7 | 1.3 |

Tailings | 98.97 | 43.6 | 62.0 | 95.5 | 0.13 | 2.33 | 93.0 | 78.1 | 25.5 | 0.13 | 2.31 | 40.6 | 48.4 | 24.4 | |

Total | 100.00 | 100.0 | 100.0 | 100.0 | - | - | - | - | - | 0.13 | 2.80 | 96.0 | 85.1 | 25.7 | |

SMMET-02 | Concentrate | 1.00 | 62.2 | 39.0 | 5.7 | 0.11 | 50.87 | 98.6 | 97.3 | 32.7 | 0.00 | 0.51 | 61.3 | 38.0 | 1.9 |

Tailings | 99.00 | 37.8 | 61.0 | 94.3 | 0.13 | 1.81 | 93.6 | 87.5 | 20.5 | 0.12 | 1.79 | 35.4 | 53.4 | 19.3 | |

Total | 100.00 | 100.0 | 100.0 | 100.0 | - | - | - | - | - | 0.12 | 2.30 | 96.7 | 91.3 | 21.2 | |

Table B1: Combined gravity + leach test results

SOURCE: Aton Resources, Inc.

View the original press release on accesswire.com