Centerra Gold Records Net Loss for 2019 of $94 million or $0.32 per Common Share Adjusted Net Earnings (Non-GAAP) of $182 million or $0.62 per Common Share; Declares Dividend of CAD$0.04 per Common Share; Provides COVID-19 Update

All figures are in United States dollars and all production figures are on a 100% basis unless otherwise stated.

TORONTO, March 26, 2020 (GLOBE NEWSWIRE) -- Centerra Gold Inc. (“Centerra” or the “Company”) (TSX: CG) today reported fourth quarter and full-year 2019 results. Key events and operating results of the fourth quarter and year included:

- Net loss for the quarter of $12.2 million, $0.04 per common share (basic) and net loss for the year of $93.5 million, $0.32 per common share (basic).

- Adjusted net earningsNG for the quarter of $22.3 million, $0.08 per common share (basic) and adjusted net earningsNG for the year of $181.5 million, $0.62 per common share (basic).

- Cash flow from operations for the quarter and year was $92.5 million and $334.1 million, respectively. Adjusted cash flow from operationsNG for the quarter and year was $92.5 million and $396.7 million, respectively.

- Gold Production for the quarter of 194,507 ounces and gold production for the year of 783,308 ounces, in excess of the high end of our full-year guidance of 765,000 ounces.

- Copper production for the quarter of 18.1 million pounds and copper production for the year of 71.1 million pounds, within our guidance range.

- Production costs per ounce of gold sold for the quarter and year were $455 per ounce and $465 per ounce, respectively.

- Production costs per pound of copper sold for the quarter and year were $1.50 per pound and $1.46 per pound, respectively.

- All-in sustaining costs per ounce soldNG for the quarter was $799 per ounce and $708 per ounce for the year, below the annual guidance range of $713 to $743 per ounce.

- Debt net of cash of $34.8 million at the end of 2019, includes cash of $42.7 million. On January 30, 2020, the Company cancelled the $150 million Öksüt Project finance facility and repaid the $78 million drawn balance which resulted in the release of $25 million in restricted cash.

- Proven and probable gold mineral reserves total an estimated 11.1 million ounces of contained gold (442 Mt at 0.78 g/t gold) at year-end, reflecting 2019 mining depletion and the impact of the updated Mount Milligan NI 43-101 technical report.

- Proven and probable copper mineral reserves total an estimated 1,589 million pounds of contained copper (298.4 Mt at 0.24% copper) at year-end, reflecting 2019 mining depletion and the impact of the updated Mount Milligan NI 43-101 technical report.

- In December 2019, the Kumtor Mine experienced a significant waste rock movement at the Lysii waste rock dump resulting in two employee fatalities.

Key events subsequent to year-end:

- In January 2020, the Company received all the necessary approvals and permits to recommence mining operations at the Kumtor Mine.

- In January 2020, the Company announced that first gold pour was achieved at the Öksüt Project. The Company completed first gold pour on time and under budget.

- In February 2020, a Kumtor employee succumbed to a fatal injury while operating an excavator near the edge of Petrov Lake.

- In March 2020, the Company filed an updated NI 43-101 technical report for the Mount Milligan Mine with an effective date of December 31, 2019.

- Dividend of CAD$0.04 per common share declared in March 2020.

All references in this document denoted with NG, indicate a non-GAAP term which is discussed under “Non-GAAP Measures” and reconciled to the most directly comparable GAAP measure.

Commentary

Scott Perry, President and Chief Executive Officer of Centerra stated, “We are fully committed to understanding the circumstances that led to the troubling safety incidents at Kumtor in December 2019 and February 2020, so that we can take all necessary steps to prevent such incidents from happening in the future. We remain steadfast in our resolve to ensure that everyone who works at our operations can do so safely and will return home safely, each and every day. There is nothing more important.”

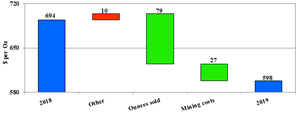

“In 2019, due to the strong operating performance at both operations, the Company exceeded its consolidated gold production and cost guidance, delivering more than 783,300 ounces of gold at an all-in sustaining costNG on a by-product basis of $708 per ounce sold, which was lower than the low-end of our all-in sustaining cost guidance. Kumtor had another strong year exceeding its revised production guidance in delivering 600,201 ounces of gold production at an all-in-sustaining cost on a by-product basis of $598 per ounce sold, which was lower than the low-end of its all-in-sustaining cost guidance. In 2019, Mount Milligan exceeded the upper end of its gold production guidance and achieved the mid-point of its copper production guidance, producing 183,107 ounces of gold and 71.1 million pounds of copper. All-in-sustaining cost on a by-product basis was above guidance at $828 per ounce sold.”

“Financially, the Company generated a meaningful $334.1 million of cash from operations for the year, Mount Milligan generated $62.2 million and Kumtor generated $376.2 million. In 2019, Kumtor generated $240 million of free cash flowNG and Mount Milligan generated $27 million which enabled the Company to aggressively pay down its debt over the year by approximately $111 million ending the year with debt net of cash of $34.8 million (excluding restricted cash).”

“Based on the Company’s financial position, recent strong operating results and cash flows, the Board approved on March 25, 2020 a dividend of Cdn$0.04 per share.”

“For 2020, we are estimating consolidated gold production to be in the range of 740,000 to 820,000 ounces combined with 80 million to 90 million pounds of payable copper production from Mount Milligan. Centerra’s consolidated all-in sustaining cost on a by-product basis per ounce soldNG for 2020 is expected to be in the range of $820 to $870 per ounce.”

“Our projected capital expenditures for 2020, excluding capitalized stripping, is estimated to be $169 million which includes $109 million of sustaining capital and $60 million of growth capital spending. Growth capital spending includes $29 million at the Öksüt Project in Turkey as we complete the construction of the site, $13 million at the Kemess Underground Project and $18 million at the Kumtor Mine. Total capitalized stripping for 2020 is estimated to be $236 million, including $215 million at the Kumtor Mine and $21 million at the Öksüt Project, with a total cash component of $193 million, including $173 million at the Kumtor Mine and $20 million at the Öksüt Project.” See “2020 Outlook” for further details.

“At Kumtor over the past 18 months we have invested significantly in exploration drilling and at year-end we can see the results as Kumtor’s open pit measured and indicated gold mineral resources increased by 3.3 million contained ounces to 6.3 million contained ounces and open pit inferred gold mineral resources increased by 1.2 million contained ounces to 1.4 million contained ounces. We are now in the process of updating Kumtor’s life-of-mine plan and an updated technical report which we plan to release in the second half of 2020.”

COVID-19 Update

Centerra continues to prioritize the health, safety and well-being of its employees, contractors, communities and other stakeholders, particularly during the current outbreak of COVID-19. To date, the Company has experienced no operating or production disruptions nor any supply chain interruptions or impact.

However, the Company has decided to undertake a significant reduction of manpower and operations at the Öksüt Project on March 31, 2020 for an initial period of two weeks. This decision was taken in response to recent Turkish government initiatives aimed to reducing the spread of COVID-19. The reduction will result in a suspension of open pit mining activities, though limited crews will remain on site to place ore on the heap leach pad, to operate the ADR plant and to perform essential site services. Approximately 150,000 tonnes of crushed material is available at site for stacking (such volume represents approximately 15 days worth of stacking activity). Öksüt has prepared detailed plans in case a further reduction or cessation of operations becomes necessary or desirable.

Kumtor and Mount Milligan operations continue for the time being and, in the case of Kumtor, with the support of the Kyrgyz Republic Government. Each site has implemented a number of proactive measures to prevent the spread of COVID-19 and ensure the safety of its employees, contractors, communities and other stakeholders. Both Kumtor and Mount Milligan have also made detailed plans in case a reduction or cessation in operations becomes necessary or desirable.

Scott Perry, President and Chief Executive Officer, commented: “The safety of our employees remains our top priority during the outbreak of COVID-19 and we are taking action based on the best available information we have. We believe that the temporary reduction of operations at Öksüt is the most prudent course of action at this juncture. Kumtor and Mount Milligan remain in operation for the time being, but we will not hesitate to reduce or shut down operations at those sites if we believe it is required to responsibly protect people.” To ensure appropriate social distancing, the Company has temporarily closed its head office in Toronto and regional offices in Bishkek, Kyrgyz Republic, Prince George, British Columbia and Ankara, Turkey and has asked its workforce to operate remotely.

To date, there are no confirmed cases of COVID-19 in the Issyk-Kul district of the Kyrgyz Republic, nor the Kayseri province of Turkey, where the Kumtor Mine and the Öksüt Mine are located, respectively, and from where they source their main workforce. To date, there has been a few reported cases in Prince George area of British Columbia from which the Mount Milligan Mine sources some of its workforce.

The Company is continuously monitoring information published by the Public Health Agency of Canada, U.S. Centers for Disease Control and Prevention (CDC), the World Health Organization (WHO) and other guidance released from appropriate government agencies.

Centerra has taken the following measures to provide its employees with accurate information, help prevent infection and reduce the potential transmission of COVID-19:

- Pandemic & Crisis Management: A global crisis management team was activated in early March. The team, comprised of executives and local site leaders, has been leading Centerra’s global response and has implemented a corporate pandemic response plan complemented by local site-specific crisis management plans.

- Health and Mental Well-being Support: Centerra continues to educate and raise awareness on COVID-19 facts and preventative actions through frequent communication with employees and is directing leaders to offer compassionate support for employees who are concerned about their wellbeing and the wellbeing of their families. Any employee who is feeling unwell or experiencing flu-like symptoms has been advised to stay home. The Company is conducting temperature checks using non-contact thermometers and asking health questions of all individuals entering any of its sites. A standard operating procedure has been implemented in case there is a need for individual isolation and subsequent transportation from site for any individual who exhibits COVID-19 related symptoms.

- Workplace Hygiene: All sites have increased daily cleaning of all common areas and spaces where there is frequent employee contact, including shared objects and any high-touch surfaces. Proper food hygiene and preparation practices have been reinforced at the Company’s mine sites which have onsite living quarters.

- Remote Working: As noted above, to promote social distancing practices, corporate and regional offices have been closed for the time being and flexible work arrangements have been implemented globally. Site employees who can work at home have been encouraged to do so. The Company has also moved to virtual meetings across the organization where possible or limited attendees at meetings while practicing prudent social distancing.

- Travel and Site Visit Restrictions: The Company has instituted a no-air travel policy. At the guidance of public health authorities, individuals who have recently returned from either business or non-business-related travel have entered a 14-day self-isolation period. In addition, a visitor ban has been instituted at all sites, including our operating mines, development projects and at our care and maintenance sites.

In addition to the above precautionary measures, operating mine sites have been actively assessing the resiliency of their supply chain, increasing mine site inventories of key materials and developing contingency plans to allow for continued operations.

The Company notes that the situation is fluid and has been changing rapidly. The measures enacted reflect the Company’s best assessment at this time but will remain flexible and be revised as necessary or advisable and/ or as recommended by the public health and governmental authorities.

About Centerra

Centerra Gold Inc. is a Canadian-based gold mining company focused on operating, developing, exploring and acquiring gold properties in North America, Asia and other markets worldwide and is the largest Western-based gold producer in Central Asia. Centerra operates two flagship assets, the Kumtor Mine in the Kyrgyz Republic, the Mount Milligan Mine in British Columbia, Canada and now has a third operating gold mine, the 100%-owned Öksüt Mine in Turkey, which began production in January 2020. Centerra's shares trade on the Toronto Stock Exchange (TSX) under the symbol CG. The Company is based in Toronto, Ontario, Canada.

Conference Call

Centerra invites you to join its 2019 conference call on Thursday, March 26, 2020 at 10:00 AM Eastern Time. The call is open to all investors and the media. To join the call, please dial toll-free in North America 1-800-952-1797. International participants may access the call at +1 416-641-6701. Results summary slides are available on Centerra Gold’s website at www.centerragold.com. Alternatively, an audio feed webcast will be broadcast live by Nasdaq Corporate Solutions and can be accessed live at Centerra Gold’s website at www.centerragold.com. A recording of the call will be available on www.centerragold.com shortly after the call and via telephone until midnight Eastern Time on April 2, 2020 by calling (416) 626-4100 or (800) 558-5253 and using passcode 21953022.

For more information:

John W. Pearson

Vice President, Investor Relations

Centerra Gold Inc.

(416) 204-1953

john.pearson@centerragold.com

Additional information on Centerra is available on the Company’s web site at www.centerragold.com and at SEDAR at www.sedar.com.

Attachment available at the following link: http://ml.globenewswire.com/Resource/Download/14bffd24-2493-44c9-95c7-88a6ce2fc5f5

Management’s Discussion and Analysis

For the Period Ended December 31, 2019

This Management Discussion and Analysis (“MD&A”) has been prepared as of March 25, 2020, and is intended to provide a review of the financial position and results of operations of Centerra Gold Inc. (“Centerra” or the “Company”) for the three and twelve months ended December 31, 2019 in comparison with the corresponding periods ended December 31, 2018. This discussion should be read in conjunction with the Company’s audited financial statements and the notes thereto for the year ended December 31, 2019 prepared in accordance with International Financial Reporting Standards (“IFRS”). The Company’s audited financial statements and the notes thereto for year ended December 31, 2019, are available at www.centerragold.com and on the System for Electronic Document Analysis and Retrieval (“SEDAR”) at www.sedar.com. All references in this document denoted with NG, indicate a non-GAAP term which is discussed under “Non-GAAP Measures” and reconciled to the most directly comparable GAAP measure. All dollar amounts are expressed in United States dollars (“USD”), except as otherwise indicated.

Caution Regarding Forward-Looking Information

Information contained in this document which are not statements of historical facts, and the documents incorporated by reference herein, may be “forward-looking information” for the purposes of Canadian securities laws. Such forward-looking information involves risks, uncertainties and other factors that could cause actual results, performance, prospects and opportunities to differ materially from those expressed or implied by such forward looking information. The words “believe”, “expect”, “anticipate”, “contemplate”, “plan”, “intends”, “continue”, “budget”, “estimate”, “may”, “will”, “schedule”, “understand” and similar expressions identify forward-looking information. These forward-looking statements relate to, among other things: statements under the heading “2020 Outlook” including expected gold and copper production in 2020, expectations regarding throughput rates per calendar day at the Mount Milligan mill, plans for maintenance work at our mines which will impact production, expectations for ramping up gold production at the Öksüt Project, production costs and all-in sustaining costs, capital spending and other expenditures expected for 2020, and expectations about the molybdenum business unit in 2020; our estimates for asset retirement obligations; the Company’s expectations regarding having sufficient liquidity for 2020; the Company’s expectations of extending the term of permits received for pumping from a wellfield; expectations regarding having sufficient water in the tailings storage facility for 2020; the Company’s plans and timing for developing and submitting requests to implement a long-term solution to the Mount Milligan water sufficiency issues, including consultations with potentially affected Indigenous groups and regulators; expectations regarding the construction completion of the Öksüt Project and timing of ramp up of operations; the expectations that the Kyrgyz Government will continue to comply with the terms of the Strategic Agreement; the outcome of the litigation involving the Company, the Greenstone Managing Partner, Premier Gold and its nominees to the Greenstone Managing Partner board of directors; the Company’s planned exploration activities; the Company’s cash on hand, working capital, future cash flows and existing credit facilities being sufficient to fund anticipated operating cash requirements and statements found under the heading “2020 Outlook”, including forecast 2020 production figures and costs, capital spending (growth and sustaining) and exploration expenditures and taxes; expectations of not needing to slow production at Mount Milligan to conserve water; and the Company will achieve Mount Milligan production and costs estimates as detailed in the updated NI 43-101 technical report for Mount Milligan.

Forward-looking information is necessarily based upon a number of estimates and assumptions that, while considered reasonable by Centerra, are inherently subject to significant political, business, economic and competitive uncertainties and contingencies. Known and unknown factors could cause actual results to differ materially from those projected in the forward-looking information. For a list of known risk factors, please see “Risks That Can Affect our Business”.

Furthermore, market price fluctuations in gold and copper, as well as increased capital or production costs or reduced recovery rates may render ore reserves containing lower grades of mineralization uneconomic and may ultimately result in a restatement of reserves. The extent to which resources may ultimately be reclassified as proven or probable reserves is dependent upon the demonstration of their profitable recovery. Economic and technological factors which may change over time always influence the evaluation of reserves or resources. Centerra has not adjusted mineral resource figures in consideration of these risks and, therefore, Centerra can give no assurances that any mineral resource estimate will ultimately be reclassified as proven and probable reserves.

Mineral resources are not mineral reserves, and do not have demonstrated economic viability, but do have reasonable prospects for economic extraction. Measured and indicated resources are sufficiently well defined to allow geological and grade continuity to be reasonably assumed and permit the application of technical and economic parameters in assessing the economic viability of the resource. Inferred resources are estimated on limited information not sufficient to verify geological and grade continuity or to allow technical and economic parameters to be applied. Inferred resources are too speculative geologically to have economic considerations applied to them to enable them to be categorized as mineral reserves. There is no certainty that mineral resources of any category can be upgraded to mineral reserves through continued exploration.

There can be no assurances that forward-looking information and statements will prove to be accurate, as many factors and future events, both known and unknown could cause actual results, performance or achievements to vary or differ materially from the results, performance or achievements that are or may be expressed or implied by such forward-looking statements contained herein or incorporated by reference. Accordingly, all such factors should be considered carefully when making decisions with respect to Centerra, and prospective investors should not place undue reliance on forward looking information. Forward-looking information is as of March 25, 2020. Centerra assumes no obligation to update or revise forward looking information to reflect changes in assumptions, changes in circumstances or any other events affecting such forward-looking information, except as required by applicable law.

TABLE OF CONTENTS

| Overview | 9 |

| Consolidated Financial and Operational Highlights | 10 |

| Overview of Consolidated Results | 11 |

| 2020 Outlook | 12 |

| Risks That Can Affect Our Business | 18 |

| Financial Performance | 20 |

| Balance Sheet Review | 23 |

| Market Conditions | 24 |

| Financial Instruments | 27 |

| Operating Mines and Facilities | 27 |

| Construction and Development Projects | 43 |

| Quarterly Results – Previous Eight Quarters | 45 |

| Related party transactions | 45 |

| Contingencies | 47 |

| Contractual Obligations | 52 |

| Accounting Estimates, Policies and Changes | 52 |

| Disclosure Controls and Procedures and Internal Control Over Financial Reporting | 53 |

| Non-GAAP Measures | 53 |

| Qualified Person & QA/QC – Production Information | 58 |

| Qualified Person & QA/QC – Mineral Reserves and Mineral Resources | 58 |

| Mineral Reserves and Mineral Resources | 59 |

Overview

Centerra is a Canadian-based gold mining company focused on operating, developing, exploring and acquiring gold properties worldwide and is one of the largest Western-based gold producers in Central Asia. Centerra’s principal operations are the Kumtor Gold Mine located in the Kyrgyz Republic, the Mount Milligan Gold-Copper Mine located in British Columbia, Canada, and the Öksüt Gold Mine in Turkey, which began production in January 2020. The Company has two properties in Canada in the pre-development stage, the Kemess Underground Gold Property and the Greenstone Gold Project (50% ownership), owns exploration properties in Canada, the United States of America and Turkey and has options to acquire exploration joint venture properties in Canada, Finland, Mexico and Turkey. The Company owns various assets included in its Molybdenum Business Unit consisting of the Langeloth metallurgical processing facility and two mines currently on care and maintenance, Thompson Creek Mine in the United States of America, and the Endako Mine in British Columbia, Canada (75% ownership).

As of December 31, 2019, Centerra’s significant subsidiaries are as follows:

| Current | Property | |||

| Entity | Property - Location | Status | Ownership | |

| Kumtor Gold Company (“KGC”) | Kumtor Mine - Kyrgyz Republic | Operation | 100% | |

| Thompson Creek Metals Company Inc. | Mount Milligan Mine - Canada | Operation | 100% | |

| Öksüt Madencilik A.S. (“OMAS”) | Öksüt Project - Turkey | Development / Commissioning(1) | 100% | |

| Langeloth Metallurgical Company LLC | Langeloth - United States | Operation | 100% | |

| AuRico Metals Inc. | Kemess Project - Canada | Pre-development | 100% | |

| Greenstone Gold Mines LP | Greenstone Gold Property - Canada | Pre-development | 50% | |

| Thompson Creek Mining Co. | Thompson Creek Mine - United States | Care and Maintenance | 100% | |

| Thompson Creek Metals Company Inc. | Endako Mine - Canada | Care and Maintenance | 75% | |

| (1) Commenced production in January 2020 | ||||

Centerra’s common shares are listed for trading on the Toronto Stock Exchange under the symbol CG. As of March 25, 2020, there are 293,814,618 common shares issued and outstanding, options to acquire 4,142,782 common shares outstanding under its stock option plan and 1,029,201 units outstanding under its restricted share unit plan (exercisable on a 1:1 basis for common shares).

The Company reports the results of its operations in U.S. dollars, however not all of its costs are incurred in U.S. dollars. As such, the movement in exchange rates between currencies in which the Company incurs costs and the U.S. dollar also impact reported costs of the Company.

Consolidated Financial and Operational Highlights

| Unaudited ($ millions, except as noted) | Three months ended December 31 | Twelve months ended December 31 | ||||||||||||||

| Financial Highlights | 2019 | 2018 | % Change | 2019 | 2018 | 2017 | % Change 2019 vs 2018 | |||||||||

| Revenue | $ | 312.5 | $ | 391.5 | (20%) | $ | 1,375.3 | $ | 1,129.3 | 1,199.0 | 22% | |||||

| Production costs | 149.4 | 172.5 | (13%) | 676.6 | 578.2 | 505.3 | 17% | |||||||||

| Standby costs | 9.1 | - | 100% | 9.1 | 10.8 | - | (16%) | |||||||||

| Depreciation, depletion and amortization | 59.3 | 63.7 | (7%) | 239.5 | 196.9 | 195.0 | 22% | |||||||||

| Earnings from mine operations | 94.7 | 155.3 | (39%) | 450.1 | 343.4 | 498.7 | 31% | |||||||||

| Net (loss) earnings | $ | (12.2 | ) | $ | 49.0 | (125%) | $ | (93.5 | ) | $ | 107.5 | 209.5 | (187%) | |||

| Adjusting items | ||||||||||||||||

| - ARO revaluation at sites on Care and Maintenance | 34.5 | 41.8 | (17%) | 34.5 | 40.4 | - | (15%) | |||||||||

| - Asset Impairment - Mount Milligan | - | - | 0% | 230.5 | - | - | 100% | |||||||||

| - Kyrgyz Republic settlement | - | - | 0% | 10.0 | - | 60.0 | 100% | |||||||||

| - Gain on sale of ATO | - | - | 0% | - | (28.0 | ) | - | (100%) | ||||||||

| - Other adjusting items | - | - | 0% | - | (1.8 | ) | 11.5 | (100%) | ||||||||

| Adjusted net earnings (3) | $ | 22.3 | $ | 90.8 | (75%) | $ | 181.5 | $ | 118.1 | 281.0 | 54% | |||||

| Cash provided by operations | 92.5 | 151.6 | (39%) | 334.1 | 217.5 | 500.9 | 54% | |||||||||

| Adjusted cash provided by operations(3) | 92.5 | 151.6 | (39%) | 396.7 | 221.9 | 500.9 | 79% | |||||||||

| Free cash flow (deficit) (3) | (0.4 | ) | 65.5 | (101%) | 34.7 | (68.4 | ) | 222.9 | 151% | |||||||

| Adjusted free cash flow (deficit)(3) | (0.4 | ) | 65.5 | (101%) | 97.3 | (64.0 | ) | 222.9 | 252% | |||||||

| Capital expenditures - sustaining | 17.8 | 23.6 | (24%) | 79.6 | 88.5 | 91.8 | (10%) | |||||||||

| Capital expenditures - growth and development projects | 42.4 | 34.3 | 23% | 148.9 | 101.5 | 32.0 | 47% | |||||||||

| Capital expenditures - stripping | 35.1 | 36.0 | (3%) | 97.2 | 138.8 | 200.2 | (30%) | |||||||||

| Total assets | $ | 2,701.7 | $ | 2,826.7 | (4%) | $ | 2,701.7 | $ | 2,826.7 | 2,772.2 | (4%) | |||||

| Long-term debt and lease obligation | 88.3 | 183.5 | (52%) | 88.3 | 183.5 | 211.6 | (52%) | |||||||||

| Cash, cash equivalents and restricted cash | 70.7 | 179.2 | (61%) | 70.7 | 179.2 | 416.6 | (61%) | |||||||||

| Per Share Data | ||||||||||||||||

| (Loss) earnings per common share - $ basic (1) | $ | (0.04 | ) | $ | 0.17 | (124%) | $ | (0.32 | ) | $ | 0.37 | 0.72 | (186%) | |||

| Adjusted net earnings per common share - $ basic (1)(3) | $ | 0.08 | $ | 0.31 | (74%) | $ | 0.62 | $ | 0.40 | 0.96 | 55% | |||||

| Per Ounce Data (except as noted) | ||||||||||||||||

| Average gold spot price ($/oz)(2) | 1,483 | 1,229 | 21% | 1,393 | 1,269 | 1,258 | 10% | |||||||||

| Average realized gold price ($/oz)(3)(4) | 1,403 | 1,158 | 21% | 1,309 | 1,175 | 1,171 | 11% | |||||||||

| Average copper spot price ($/lb)(2) | 2.68 | 2.79 | (4%) | 2.73 | 2.96 | 2.61 | (8%) | |||||||||

| Average realized copper price ($/lb)(3)(4) | 2.23 | 1.76 | 27% | 2.09 | 2.02 | 2.11 | 3% | |||||||||

| Operating Highlights | ||||||||||||||||

| Gold produced (oz's) | 194,507 | 288,367 | (33%) | 783,308 | 729,556 | 785,316 | 7% | |||||||||

| Gold sold (oz's) | 169,892 | 269,754 | (37%) | 780,654 | 709,330 | 792,466 | 10% | |||||||||

| Payable Copper Produced (000's lbs) | 18,079 | 11,796 | 53% | 71,146 | 47,091 | 53,596 | 51% | |||||||||

| Copper Sales (000's payable lbs) | 14,301 | 13,591 | 5% | 67,430 | 44,370 | 59,719 | 52% | |||||||||

| Unit Costs | ||||||||||||||||

| Production costs per ounce of gold sold (4) | $ | 455 | $ | 375 | 21% | $ | 465 | $ | 464 | 360 | 0% | |||||

| Gold - All-in sustaining costs on a by-product basis ($/oz sold)(3)(4) | $ | 799 | $ | 576 | 39% | $ | 708 | $ | 754 | 687 | (6%) | |||||

| Gold - All-in sustaining costs on a by-product basis (including taxes) ($/oz sold)(3) (4) | $ | 969 | $ | 709 | 37% | $ | 862 | $ | 889 | 815 | (3%) | |||||

| Gold - All-in sustaining costs on a co-product basis (before taxes) – ($/oz sold)(3)(4) | $ | 829 | $ | 573 | 45% | $ | 737 | $ | 750 | 737 | (2%) | |||||

| Production costs per pound of copper sold (4) | 1.50 | 1.33 | 13% | 1.46 | 1.26 | 1.48 | 16% | |||||||||

| Copper - All-in sustaining costs on a co-product basis (before taxes) – ($/pound sold)(3)(4) | $ | 2.28 | $ | 1.53 | 49% | $ | 1.85 | $ | 1.77 | 1.47 | 5% | |||||

| (1) As at December 31, 2019, the Company had 293,690,456 common shares issued and outstanding. | ||||||||||||||||

| (2) Average for the period as reported by the London Bullion Market Association (US dollar Gold P.M. Fix Rate) and London Metal Exchange (LME). | ||||||||||||||||

| (3) Non-GAAP measure. See discussion under “Non-GAAP Measures”. | ||||||||||||||||

| (4) Combines streamed and unstreamed amounts. | ||||||||||||||||

Overview of Consolidated Results

Fourth Quarter 2019 compared to Fourth Quarter 2018

Net loss of $12.2 million and adjusted net earningsNG of $22.3 million in the fourth quarter of 2019, compared to net earnings and adjusted net earningsNG of $49.0 million and $90.8 million, respectively, in the fourth quarter of 2018. The decrease in adjusted net earningsNG in the fourth quarter of 2019 was due to lower gold grades at Kumtor and Mount Milligan and costs related to the significant waste rock movement at Kumtor’s Lysii waste rock dump, partially offset by higher average gold prices in 2019 together with higher copper grades processed at the Mount Milligan Mine.

Significant adjusting items to the net loss in the fourth quarter of 2019 include:

- $34.5 million asset retirement obligation (“ARO”) expense at the Company’s non-operating sites, due primarily to a change in discount rates.

Significant adjusting items to net earnings in the fourth quarter of 2018 include:

- $40.4 million ARO expense at the Company’s non-operating sites, due primarily to a change in the underlying closure plan at the Thompson Creek Mine.

Cash provided by operations was $92.5 million in the fourth quarter of 2019, compared to $151.6 million in the same prior year period, due to the decrease in adjusted net earningsNG, increase in inventory and decrease in accounts payable at Mount Milligan, partially offset by an increase in accounts payable at Kumtor. Negative free cash flow NG of $0.4 million in the fourth quarter of 2019 compared to positive free cash flowNG of $65.5 million in the same period of 2018, consistent with the change in adjusted net earningsNG.

Year ended December 31, 2019 compared to 2018

Net loss of $93.5 million and adjusted net earningsNG of $181.5 million in 2019, compared to net earnings and adjusted net earningsNG of $107.5 million and $118.1 million, respectively, in 2018.

The increase in adjusted net earningsNG in the current year was due to increased gold sales at Kumtor and Mount Milligan, increased copper sales at Mount Milligan and higher realized gold prices. At Kumtor, the increase in gold sold was as a result of processing higher grade ore and achieving higher recoveries. At Mount Milligan the increased sales levels reflect additional concentrate shipments during the year due to higher mill availability and throughput, coupled with higher copper grades and higher gold recoveries.

Significant adjusting items to the net loss in 2019 include:

- $230.5 million impairment charge on the assets at the Mount Milligan Mine,

- $34.5 million ARO expense at the non-operating sites due to a significant change in the discount rate assumption, and

- $10.0 million charge relating to the completion of the Strategic Agreement with the Kyrgyz Government.

Significant adjusting items to net earnings in 2018 include:

- $40.4 million ARO expense at the non-operating sites due to changes in the underlying closure models, partially offset by,

- $28.0 million gain on the sale of the Company’s royalty portfolio that was acquired as part of the AuRico Metals Inc. acquisition.

Cash provided by operations was $334.1 million in 2019, which included the Kyrgyz Republic settlement payment of $62.6 million, compared to $217.5 million in the same prior year period. Excluding this payment, adjusted cash provided by operationsNG for 2019 was $396.7 million compared to $221.9 million in 2018 due to higher revenue as a result of increased gold sold at Kumtor, increased copper sold at Mount Milligan and higher realized gold prices. There was also an increase in cash from working capital due to a larger increase in accounts payable balances at Kumtor, Mount Milligan and the corporate office in 2019 compared to 2018, partially offset by a larger increase in the accounts receivable balance at Mount Milligan, due to the timing of shipments in 2019 compared to 2018. The increase in adjusted free cash flow NG of $97.3 million in 2019 compared to negative adjusted free cash flow NG of $64.0 million in 2018 is due to an increase in cash provided by operations and decrease in capitalized stripping at Kumtor, partially offset by an increase in capital expenditures at Öksüt. The negative adjusted free cashflowNG of $64.0 million in 2018 was primarily due to lower sales and earnings at Kumtor and Mount Milligan.

Safety and Environment

On December 1, 2019, a significant waste rock movement occurred at Kumtor’s Lysii waste rock dump resulting in two employee fatalities. After six weeks of continuous search efforts and with the consent of the families and the relevant Kyrgyz state agencies, the search was concluded. Investigations involving the Kyrgyz State Inspectorate for Environmental and Technical Safety as well as internal investigations by Centerra Gold are currently underway. Including these two fatalities, Centerra incurred fourteen reportable injuries in the fourth quarter of 2019, including six lost time injuries, six medical aid injuries and two restricted work injuries.

On February 15, 2020, a Kumtor employee succumbed to a fatal injury while operating an excavator, which tipped and then slipped down into a water-filled basin near the edge of Petrov Lake. An internal investigation has commenced, and management is working closely with the Kyrgyz regulators and other state authorities to ascertain the cause of the incident.

There were no reportable releases to the environment in the fourth quarter and for the 2019 year.

2020 Outlook

The Company has been monitoring closely developments relating to COVID19 and has taken a number of proactive measures to ensure the safety of its employees and the continuity of its business. To date, the Company has experienced no operating or production disruptions nor any supply chain interruptions or impact.

However, the Company has decided to undertake a significant reduction of manpower and operations at the Öksüt Project on March 31, 2020 for an initial period of two weeks. This decision was taken in response to recent Turkish government initiatives aimed to reducing the spread of COVID-19. The reduction will result in a suspension of open pit mining activities though, limited crews will remain on site to place ore on the heap leach pad, to operate the ADR plant and to perform essential site services. Approximately 150,000 tonnes of crushed material is available at site for stacking (such volume represents approximately 15 days worth of stacking activity). Öksüt has prepared detailed plans in case a further reduction or cessation of operations becomes necessary or desirable. This short-term cessation of mining is not expected to impact 2020 production guidance as estimated at December 31, 2019.

Kumtor and Mount Milligan operations continue for the time being and, in the case of Kumtor, with the support of the Kyrgyz Republic Government. Each site has implemented a number of proactive measures to prevent the spread of COVID-19 and ensure the safety of its employees, contractors, communities and other stakeholders. Both Kumtor and Mount Milligan have also made detailed plans in case a reduction or cessation in operations becomes necessary or desirable.

Despite its best efforts, the Company notes that COVID-19 has the potential to significantly further disrupt Centerra’s operations. Among other things, COVID19 has the potential to cause significant illness in our workforce, temporarily shut down mining, milling and other operations, disrupt supply chains as well as rail and shipping networks used to deliver our products to customers. While Centerra has taken and will continue to take measures to mitigate such risks, the global effects of COVID19 are rapidly evolving and cannot be predicted.

The guidance in this Outlook section has been largely reproduced from the Company’s news release of February 11, 2020 for ease of reference. However, the Company cautions that due to the rapidly evolving risks relating to COVID-19, the guidance set out below will not reflect the Company’s estimates of its 2020 performance if there are any further significant disruptions to any of its operations. Readers are therefore cautioned to carefully consider the foregoing paragraphs of this Outlook section and the risks identified elsewhere in this document and in Centerra’s most recently filed Annual Information Form.

2020 Gold Production Guidance

Centerra’s 2020 gold production is expected to be between 740,000 to 820,000 ounces.

Kumtor Mine’s gold production forecast is expected to be in the range of 520,000 ounces to 560,000 ounces. A planned shutdown of the processing plant, for the replacement of the SAG Mill girth gear, SAG Mill pinion and Ball Mill electrical motor occurred in December 2019 and the processing plant was successfully restarted in early-January. This shutdown is expected to reduce production levels in the first quarter of 2020. For 2020, 100% of the ore feed for the processing plant will come from existing ore stockpiles on surface.

At Mount Milligan, the Company expects to achieve an average daily throughput of approximately 55,000 tonnes per calendar day for the full year. Crusher maintenance was completed during January. Further mill maintenance downtime is scheduled for the first quarter (9-days) and third quarter (8-days) to complete SAG Mill relines and other maintenance work. The Company notes that any delays in the completion of such work, due to COVID19 or otherwise, may result in a potentially prolonged period during which the mill could be shut down. Mount Milligan’s total payable gold production is forecast to be in the range of 140,000 to 160,000 ounces. During the first half of 2020, lower than the expected 2020 average gold and copper grades are planned to be processed resulting in lower first half production. Gold and copper grades and metal production is expected to increase over the second half of 2020. The Company continues to work on several continuous improvement projects including electrification of all pumping equipment, groundwater exploration and remediation of the secondary crushing circuit and is actively reducing costs throughout the operation, including the removal of a layer of management in January 2020.

At Öksüt, first gold pour occurred on January 31 and 2020 gold production is expected to be in the range of 80,000 to 100,000 ounces with gold production expected to ramp up over the course of the year.

2020 Copper Production Guidance

Centerra expects total payable copper production from the Mount Milligan Mine to be in the range of 80 to 90 million pounds.

Centerra’s 2020 production is currently forecast as follows:

| Units | Kumtor | Mount Milligan(1) | Öksüt | Centerra | |

| Gold | |||||

| Unstreamed Gold Payable Production | (Koz) | 520-560 | 91-104 | 80-100 | 691-764 |

| Streamed Gold Payable Production(1) | (Koz) | - | 49-56 | - | 49-56 |

| Total Gold Payable Production(2) | (Koz) | 520-560 | 140-160 | 80-100 | 740-820 |

| Copper | |||||

| Unstreamed Copper Payable Production | (Mlb) | - | 65-73 | - | 65-73 |

| Streamed Copper Payable Production(1) | (Mlb) | - | 15-17 | - | 15-17 |

| Total Copper Payable Production(3) | (Mlb) | - | 80-90 | - | 80-90 |

| (1) The Mount Milligan Streaming Arrangement entitles Royal Gold to 35% and 18.75% of gold and copper sales, respectively, from the Mount Milligan Mine. Under the Mount Milligan Streaming Arrangement, Royal Gold will pay $435 per ounce of gold delivered and 15% of the spot price per metric tonne of copper delivered. | |||||

| (2) Gold production assumes recoveries of 82.4% at Kumtor, 64% at Mount Milligan and approximately 60% at Öksüt. | |||||

| (3) Copper production assumes 81.9% recovery for copper at Mount Milligan. | |||||

2020 Sales and All-in Sustaining Unit Costs GuidanceNG

Centerra’s 2020 sales and all-in sustaining costs per ounce sold NG (“AISC”) calculated on a by-product basis, are forecasted as follows:

| Units | Kumtor | Mount Milligan(2) | Öksüt | Centerra(2)(4) | |

| Ounces sold | (Koz) | 520-560 | 140-160 | 80-100 | 740-820 |

| Production costs per ounce of gold sold | ($/oz) | $300-$360 | $750-$800 | $375-$550 | $450-$500 |

| All-in sustaining costs on a by-product basis(1), (2) | ($/oz) | $750-$800 | $885-$935 | $650-$700 | $820-$870 |

| Revenue-based tax and taxes(3) | ($/oz) | $190-$205 | $20-$24 | $10-$12 | $130-$140 |

| All-in sustaining costs on a by-product basis, including taxes(1), (2), (3) | ($/oz) | $940-$1,005 | $905-$959 | $660-$712 | $950-$1,010 |

| Gold - All-in sustaining costs on a co-product basis(1), (2) | ($/oz) | $750-$800 | $970-$1,220 | $650-$700 | $825-$925 |

| Production costs per pound of copper sold | ($/lb) | - | $1.30-$1.40 | - | $1.30-$1.40 |

| Copper - All-in sustaining costs on a co-product basis(1), (2) | ($/lb) | - | $1.70-$2.10 | - | $1.70-$2.10 |

| (1) All-in sustaining costs per ounce sold, all-in sustaining costs per ounce sold on a by-product basis, all-in sustaining costs on a by-product basis including taxes per ounce sold and all-in sustaining costs on a co-product basis (gold and copper) on a per unit basis are non-GAAP measures and are discussed under “Non-GAAP Measures”. | |||||

| (2) Mount Milligan payable production and ounces sold are on a 100% basis (the Mount Milligan Streaming Arrangement entitles Royal Gold to 35% and 18.75% of gold and copper sales, respectively). Unit costs and consolidated unit costs include a credit for forecasted copper sales treated as by-product for all-in sustaining costs and all-in sustaining costs plus taxes. Payable production for copper and gold reflects estimated metallurgical losses resulting from handling of the concentrate and payable metal deductions, subject to metal content, levied by smelters. | |||||

| (3) Includes revenue-based tax at Kumtor, British Columbia mineral tax at Mount Milligan and income tax at Öksüt. | |||||

| (4) Results in chart may not add due to rounding. | |||||

Production costs per ounce of gold sold are included as a new guidance measure and is considered the nearest GAAP measure to AISC. AISC is defined in the non-GAAP section of this MD&A, and includes production costs, as presented in the financial statements, as well as sustaining capital, capitalized stripping, corporate administration costs and various “other costs”, and a credit for copper sales ranging from $175 to $197 million for 2020. At Mount Milligan, “other costs” include approximately $20 million for treatment and refining charges and $10 million for marketing costs. In 2020, at Kumtor, “other costs” include approximately $10 million as contributions to various development funds in the Kyrgyz Republic.

2020 Capital Spending

Projected capital expenditures include:

| Capitalized | Sustaining | Growth | ||

| Projects ($ millions) | Stripping | Capital | Capital | Total |

| Kumtor Mine(1) | 215 | 49 | 18 | 282 |

| Mount Milligan Mine | - | 55 | - | 55 |

| Öksüt Mine(1) | 21 | - | 29 | 50 |

| Kemess Underground Project | - | - | 13 | 13 |

| Other(2) | - | 5 | - | 5 |

| Consolidated Total | $236 | $109 | $60 | $405 |

| (1) Capitalized stripping includes a cash component of $173 million (Kumtor Mine), and $20 million (Öksüt Mine). | ||||

| (2) Thompson Creek Mine, Endako Mine (75% ownership), Langeloth facility, and Corporate. | ||||

Kumtor Mine

Spending on sustaining capital of $49 million relates primarily to major overhauls, purchase of vehicles and dewatering projects.

Growth capital investment at Kumtor for 2020 is forecast at $18 million which includes capital expenditures for the tailings dam lift required to allow for production from cutback 20 and cost related to the construction of the effluent treatment plant.

Mining activities at Kumtor in 2020 will be focused on stripping cutback 20. The cash component of capitalized stripping costs related to the development is expected to be $173 million of the $215 million total capitalized stripping estimated in 2020.

Mount Milligan Mine

Sustaining capital expenditures are forecast to be $55 million and relate primarily to tailings storage facility costs, major overhauls and water management costs.

Öksüt Mine

Growth capital investment for 2020 is forecast at $29 million as the Company completes the construction of the site.

The cash component of capitalized stripping costs related to the development of the open pit is expected to be $20 million of the $21 million total capitalized stripping estimated in 2020.

Kemess Underground Project

In 2020, total spending at Kemess is estimated at $35 million, including $22 million for care and maintenance for the year. The Company has authorized $13 million of capitalized pre-construction spending at the Kemess Underground Project, with further spending subject to board approval.

Greenstone Gold Property

The 2020 expenditures relating to the Greenstone Gold Property (50-50 joint venture with Premier Gold) including the Hardrock Project continue to be under review given the ongoing legal dispute between the Company and Premier Gold.

2020 Exploration Expenditures

Planned exploration expenditures for 2020 are expected to be $50 million, including approximately $32 million for brownfields exploration (Kumtor - $20 million, Mount Milligan - $7 million, Öksüt - $3 million and Kemess - $2 million) and the balance for greenfields and generative exploration programs.

2020 Corporate Administration

Corporate and administration expense for 2020 is forecast to be between $32 million and $38 million (including $6 million to $8 million of stock-based compensation expense).

2020 Depreciation, Depletion and Amortization

Consolidated depreciation, depletion and amortization (DD&A) expense included in costs of sales expense for 2020 is forecasted to be in the range of $295 to $345 million, including Kumtor’s DD&A expense of $235 to $255 million, Mount Milligan’s DD&A expense of $40 million to $60 million, and Öksüt’s DD&A expense of $20 to $30 million.

2020 Taxes

Pursuant to the Restated Investment Agreement, Kumtor’s operations are not subject to corporate income taxes. Instead, the Restated Investment Agreement imposes a tax of 13% on gross revenue plus 1% for the Issyk-Kul Oblast Development Fund. The Mount Milligan operations are subject to corporate income tax and British Columbia mineral tax. At Öksüt, income tax is expected to be between $1 to $2 million. Corporate income tax for 2020 is forecast to be nil, while British Columbia mineral tax is forecast to be between $2 and $4 million.

2020 Financing Costs

Financing costs for 2020 are expected to be $5 to $7 million. As at December 31, 2019 the Company’s cash balance was approximately $43 million (excluding $28 million of restricted cash) and the outstanding debt balance was $78 million (Öksüt facility). At the end of 2019, the CAT lease facility of $27 million was repaid and the Öksüt facility with a drawn balance of $78 million was repaid on January 30, 2020 using lower cost funds from the Company’s corporate credit facility. In 2020, the Company expects to utilize the corporate credit facility and then expedite its repayment using available cash flow.

Molybdenum Business Unit

In 2020, the Company expects that the Langeloth metallurgical roasting facility, forming part of the molybdenum business, will not generate sufficient operating margins to cover the costs of its two molybdenum mines on care and maintenance. This assumption is based on a decline in the molybdenum price late in 2019. Care and maintenance expenses related to the Molybdenum unit are currently estimated to be between $12 million and $14 million for 2020.

Sensitivities

Centerra’s revenues, earnings and cash flows for 2020 are sensitive to changes in certain key inputs or currencies. The Company has estimated the impact of any such changes on revenues, net earnings and cash from operations.

| Impact on ($ millions) | Impact on ($ per ounce sold) | ||||||||

| Production Costs & Taxes | Capital Costs | Financing Costs | Revenues | Cash flows | Net Earnings (after tax) | AISC(2)(3) on by-product basis | |||

| Gold price | $50/oz | 5.1 - 5.6 | - | 1.5 - 1.6 | 34.5 - 38.2 | 27.9 - 31.0 | 27.9 - 31.0 | 0.2 - 0.5 | |

| Copper price | 10% | 4.7 - 5.3 | - | 0.6 - 0.7 | 17.0 - 19.0 | 11.7 - 13.0 | 11.7 - 13.0 | 21 - 23 | |

| Diesel fuel(4) | 10% | 4.9 - 6.0 | - | - | - | 4.9 - 6.0 | 4.9 - 6.0 | 7 - 8 | |

| Kyrgyz som(1) | 1 som | 1.2 - 1.6 | - | - | - | 1.2 - 1.6 | 1.2 - 1.6 | 1.5 - 2.0 | |

| Turkish lira(1) | 1 lira | 4.5 - 5.0 | 1.5 - 2.5 | - | - | 5.5 - 7.5 | 4.0 - 5.0 | 8 - 9 | |

| Canadian dollar(1)(4) | 10 cents | 8.5 - 10.0 | 4.1 - 4.8 | - | - | 12.6 - 14.8 | 8.5 - 10.0 | 13 - 15 | |

| (1) Appreciation of currency against the U.S. dollar will result in higher costs and lower cash flow and earnings, depreciation of currency against the U.S. dollar results in decreased costs and increased cash flow and earnings. | |||||||||

| (2) Non-GAAP measure. See discussion under “Non-GAAP Measures” | |||||||||

| (3) AISC is calculated over the full year ounces sold forecast. | |||||||||

| (4) Includes the effect of hedging programs. | |||||||||

Production, cost and capital forecasts for 2020 are forward-looking information and are based on key assumptions and subject to material risk factors that could cause actual results to differ materially and which are discussed herein under the headings “Material Assumptions” and “Caution Regarding Forward-Looking Information” in this document and under the heading “Risks That Can Affect Our Business” in this document and the Company’s most recently filed Annual Information Form.

Material Assumptions

Material assumptions or factors used to forecast production and costs for 2020 include the following:

- a gold price of $1,350 per ounce

- a copper price of $2.60 per pound

- a molybdenum price of $10.75 per pound

- exchange rates:

° $1USD:$1.30 Canadian dollar,

° $1USD:69.50 Kyrgyz som,

° $1USD:5.50 Turkish lira,

° $1USD:0.85 Euro. - diesel fuel price assumption:

° $0.50/litre at Kumtor,

° $0.81/litre (CAD$1.06/litre) at Mount Milligan.

The assumed diesel price of $0.50/litre at Kumtor assumes that no Russian export duty will be paid on the fuel exports from Russia to the Kyrgyz Republic. Diesel fuel for Kumtor is sourced from separate Russian suppliers. The diesel fuel price assumptions were made when the oil price was approximately $66 per barrel. Crude oil is a component of diesel fuel purchased by the Company, such that changes in the price of Brent crude oil generally impacts diesel fuel prices. The Company established a hedging strategy to manage changes in diesel fuel prices on the cost of operations at the Kumtor Mine with the objective to hedge approximately 75% of Kumtor’s 2020 diesel purchases. The oil price has significantly decreased from January 1, 2020. The company is currently re-evaluating its diesel procurement strategy together with its hedging strategy, this may include holding higher levels of diesel at the Kumtor mine and the hedging strategy extending beyond the current 12-month period.

Other material assumptions used in forecasting production and costs for 2020 can be found under the heading “Caution Regarding Forward-Looking Information” in this document. Production, cost and capital forecasts for 2020 are forward-looking information and are based on key assumptions and subject to material risk factors that could cause actual results to differ materially and which are discussed under the heading “Risks That Can Affect Our Business” in this document and in the Company’s most recent Annual Information Form.

Risks That Can Affect Our Business

Overview

The Company is subject to risks that can have a material effect on the profitability, future cash flow, stated mineral reserves and financial condition of the Company. Some of these risks relate to the mining industry in general, and others apply to specific properties, operations or planned operations. The Company has adopted an enterprise risk management program which applies to all of our operations and corporate offices. This broad, systematic approach is used to identify, assess, report and manage the significant risks that the Company faces in our business and operations. The Company uses a common risk matrix throughout the organization and considers any risk that has the potential to significantly affect our ability to achieve our corporate objectives or strategic plan as an enterprise risk.

Board and Committee Oversight

The Company has a Risk Committee of the Board of Directors which has oversight responsibilities in relation to the policies, processes and systems for the identification, assessment and management of the Company’s principal strategic, financial, and operational risks. To ensure cross-communication of risks amongst Board committees, the members of the Risk Committee are comprised of at least one member from each of the other standing committees of the Board. Each of the other Board committees are responsible for overseeing risks related to their area of expertise and reviewing the policies, standards and actions undertaken to mitigate such risks.

Management Oversight

The Company’s executive team meets regularly with our Vice President, Risk Management and Insurance to review the risks applicable to the organization in general, and to specific sites, and to discuss mitigation actions. The Company’s Vice President, Risk Management and Insurance in turn has regular calls and meetings with counterparts at the operations and sites to raise and discuss risks facing the operations and mitigation actions.

Principal risks

The following section describes the risks that are most material to our business. This is not, however, a complete list of the potential risks we face; there may be others we are not aware of, or risks we feel are not material today that could become material in the future. For a more comprehensive discussion about our risks, see our most recently filed Annual Information Form.

Strategic, legal, planning and other risks

These include political risks associated with the Company’s operations in the Kyrgyz Republic, Turkey and Canada; resource nationalism; reliance on cash flow from its subsidiaries; the impact of changes in, or more aggressive enforcement of laws, regulations and government practices including with respect to the environment; impact of community activism on laws and regulations; increases in contributory demands, or business interruption; delays or refusals to grant required permits and licenses; status of our relationships with local communities; Indigenous claims and consultative issues relating to the Company’s properties which are in proximity to Indigenous communities; the risks related to outstanding litigation affecting the Company; the impact of any sanctions imposed by Canada, the United States or other jurisdictions against various Russian and Turkish individuals and entities; potential defects of title in the Company’s properties that are not known as of the date hereof; the inability of the Company and its subsidiaries to enforce their legal rights in certain circumstances; the presence of a significant shareholder that is a state-owned company of the Kyrgyz Republic; conflicts of interest among its board members; risks related to anti-corruption legislation; Centerra’s future exploration and development activities not being successful; Centerra not being able to replace mineral reserves and resources; risks related to disagreements with partners; risks related to mineral reserves and resources being imprecise; our production and cost estimates may be inaccurate; reputational risks, particularly in light of the increase in social media; ability to identify new opportunities and to grow the business; large fluctuations in the Company’s trading price that are beyond the Company’s control or ability to predict and mitigate; potential risks related to kidnapping or acts of terrorism; and competition amongst mining companies for acquisition or development opportunities.

Financial Risks

The Company is subjected to risks related to its financial position and liquidity, including sensitivity of the Company’s business to the volatility of gold, copper and other mineral prices; the use of provisionally-priced sales contracts for production at Mount Milligan; reliance on a few key customers for the gold-copper concentrate at Mount Milligan; use of commodity derivatives; sensitivity to fuel price volatility; the impact of currency fluctuations; global financial conditions; access to future financing including the impact of our environmental, social and corporate governance (“ESG”) practices and reporting on our ability to obtain future financing or accessing capital; the impact of restrictive covenants in the Company’s credit facilities which may, among other things, restrict the Company from pursuing certain business activities or making distributions from its subsidiaries; the effect of market conditions on the Company’s short-term investments; the Company’s ability to make payments including any payments of principal and interest on the Company’s debt facilities depends on the cash flow of its subsidiaries; ability to obtain adequate insurance coverage; and changes to taxation laws in the jurisdictions where we operate.

Operational Risks

Mining and metals processing involve significant production and operational risks. Some of these risks are outside of the Company’s control or ability to predict and mitigate. Risks include but are not limited to the following: unanticipated ground and water conditions; shortages of water for processing activities; adjacent or adverse land or mineral ownership that results in constraints on current or future mine operations; geological problems, including earthquakes and other natural disasters; metallurgical and other processing problems; unusual or unexpected mineralogy or rock formations; ground or slope failures; pit flooding; tailings design or operational issues, including dam breaches or failures; structural cave-ins, wall failures or rock-slides; flooding or fires; equipment failures or performance problems; periodic interruptions due to inclement or hazardous weather conditions or operating conditions and other force majeure events; lower than expected ore grades or recovery rates; accidents; delays in the receipt of, or failure to receive, necessary government permits; delays in transportation, including disruption in rail and shipping networks caused by COVID19; interruption of energy supply; labour disturbances; the availability of drilling and related equipment in the area where mining operations will be conducted; the failure of equipment or processes to operate in accordance with specifications or expectations; tailings management facilities; exposure of workforce to widespread pandemic (including COVID19); cyanide use; regulations regarding greenhouse gas emissions and climate change; development and construction costs being over budget; predicting decommissioning and reclamation costs; attracting and retaining qualified personnel; long lead times required for equipment and supplies given the remote location of some of the Company’s operating properties, and the potential that COVID19 could disrupt such supply chains; reliance on a limited number of suppliers for certain consumables, equipment and components; and security of critical operating systems.

Financial Performance

Fourth Quarter 2019 compared to Fourth Quarter 2018

Revenue:

Revenue decreased to $312.5 million in the fourth quarter of 2019 from $391.5 million in the comparative prior year period, as a result of 37% fewer gold ounces sold compared to 2018, partially offset by 21% higher average realized gold price and 5% more copper pounds sold.

Production:

Gold production in the fourth quarter of 2019 was 194,507 ounces compared to 288,367 ounces for the same prior year period. Gold production at Kumtor was 148,523 ounces in the fourth quarter of 2019, 35% less than the same period of 2018. The decrease in ounces produced at Kumtor was a result of processing lower grade ore, lower recoveries and a comprehensive mill shutdown in December to replace equipment. During the fourth quarter for 2019, Mount Milligan produced 45,984 ounces of gold, a 24% decrease from the same prior year period due to lower gold grades processed. Copper production at Mount Milligan during the fourth quarter of 2019 was 18.1 million pounds, 6.3 million pounds more than the comparative prior year period, reflecting higher grades, partially offset by lower recoveries.

Production costs per ounce of gold sold:

Production costs per ounce of gold sold increased in the fourth quarter of 2019 to $455 compared to $375 in the same period of 2018, mainly due to lower sales volumes at both operating mines.

All-in Sustaining CostsNG:

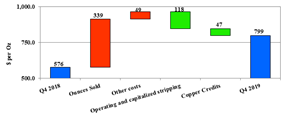

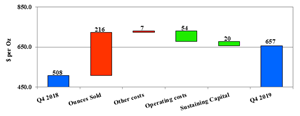

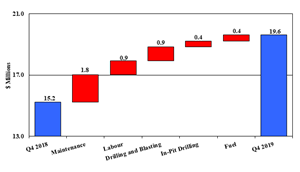

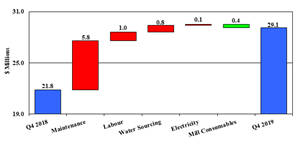

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/c2cab1f7-7e47-4c4a-b376-92537f661187

Centerra’s all-in sustaining costs on a by-product basis per ounce of gold soldNG, which excludes revenue-based tax and income tax, increased to $799 per ounce in the fourth quarter of 2019, up from $576 per ounce in the same prior year period due primarily to fewer ounces sold, partially offset by higher copper credits and lower production costs.

Exploration:

Exploration expenditures in the fourth quarter of 2019 were $9.1 million compared to $6.5 million in the comparative prior year period. The increase was due to an additional $1.0 million spent on drilling at each of the Kumtor and Mount Milligan mines.

Financing costs:

Financing costs in the fourth quarter of 2019 were $4.3 million compared to $4.9 million in the comparative prior year period, reflecting the Company’s repayment of the principal outstanding on its Corporate Facility.

Corporate administration:

Corporate administration costs were $9.2 million in the fourth quarter of 2019, an increase of $2.7 million compared to the same period of 2018, mainly due to an increase in employee and other costs.

Year ended December 31, 2019 compared to 2018

Revenue:

Revenue increased to $1,375.3 million in 2019 from $1,129.3 million in the comparative year, as a result of 10% more gold ounces sold, 11% higher average realized gold price, 52%more copper pounds sold and 2% higher molybdenum sales as compared to 2018.

Production:

Gold production for 2019 was 783,308 ounces compared to 729,556 ounces in 2018. Gold production at Kumtor was 600,201 ounces in 2019, 65,638 ounces (12%) more than the comparative year. The increase in ounces produced at Kumtor was a result of milling higher-grade ore (3.7g/t compared to 3.3g/t) and higher recoveries (83.5%compared to 79.3%). During 2019, although Mount Milligan recorded 21% higher throughput, it produced 183,107 ounces of gold, 6%lower than in 2018, as a result of lower grades (0.5g/t compared to 0.7g/t). Mount Milligan produced 71.1 million pounds of copper, 51%more than in 2018, reflecting higher throughput and grades (0.26%compared to 0.20%).

Production costs per ounce of gold sold:

Production costs per ounce of gold sold increased in 2019 to $465 from $464 in 2018 due to higher mining and milling costs per ounce at Mount Milligan, partially offset by higher sales volumes at Kumtor.

All-in Sustaining CostsNG:

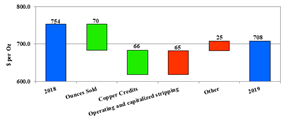

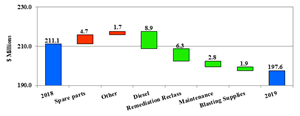

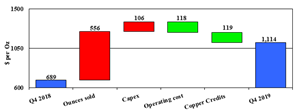

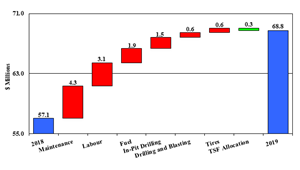

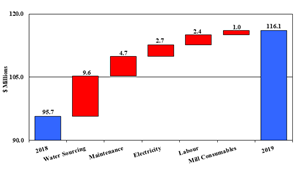

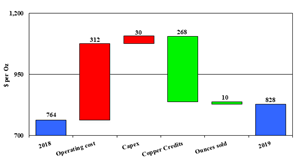

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/0ae9a411-fc48-4cea-82fc-71fc6a09d66a

All-in sustaining costs on a by-product basis per ounce of gold soldNG, which excludes revenue-based tax and income tax, decreased to $708 per ounce in 2019 from $754 per ounce in the comparative year mainly as a result of significantly more ounces sold and lower capitalized stripping costs at Kumtor, resulting in a 14% decrease in Kumtor’s all-in sustaining costNG. This was partially offset by an 8% increase in all-in sustaining costsNG at Mount Milligan attributable to higher production costs, partially offset by higher copper credits.

Exploration:

Exploration expenditures in 2019 were $28.0 million, a 34% increase compared to the $20.9 million in 2018, reflecting the increased exploration spending at Kumtor, Mount Milligan and Kemess in 2019.

Financing costs:

Financing costs in 2019 were $16.3 million compared to $30.7 million in the comparative year, reflecting the Company’s repayment of its Corporate Facility, which resulted in lower interest expense, and lower financing costs and fees.

Corporate administration:

Corporate administration costs increased to $45.3 million in 2019 compared to $29.6 million in the prior year, mainly due to an increase in share-based compensation of $15.3 million, driven by an increase in the Company’s share price, partially offset by administration costs in 2018 associated with the Company’s acquisition of AuRico Metals Inc (“AuRico”).

Balance Sheet Review

| $ millions | Year ended December 31, | |||

| 2019 | 2018 | Change | ||

| Consolidated: | ||||

| Cash and cash equivalents | 42.7 | 151.7 | (72%) | |

| Inventories | 774.1 | 577.4 | 34% | |

| Current assets | 115.9 | 85.3 | 36% | |

| Property, plant and equipment | 1,669.5 | 1,905.5 | (12%) | |

| Non-current assets | 99.5 | 106.7 | (7%) | |

| Total Assets | 2,701.7 | 2,826.7 | (4%) | |

| Current debt | - | 5.0 | (100%) | |

| Current liabilities | 244.8 | 229.8 | 7% | |

| Non-current Debt | 70.0 | 179.3 | (61%) | |

| Provision for reclamation | 265.0 | 212.2 | 25% | |

| Non-current liabilities | 56.0 | 52.4 | 7% | |

| Total Liabilities | 635.9 | 678.7 | (6%) | |

| Total Equity | 2,065.8 | 2,148.0 | (4%) | |

| Total Liabilities and Equity | 2,701.7 | 2,826.7 | (4%) | |

Cash and cash equivalents

Cash and cash equivalents decreased by $109.0 million from December 31, 2018 to the end of 2019 as the Company paid down its current and non-current debt by $111 million.

Inventory

Total inventory at December 31, 2019 was $774.1 million compared to $577.4 million at the end of 2018. Inventory on hand included product inventory of $564.7 million and supplies inventory of $209.3 million, compared to $389.3 million and $188.2 million, respectively, at the end of 2018. The increase in product inventory was primarily attributable to an increase at Kumtor of $161.6 million in product inventory due to the additional ounces mined and stockpiled in 2019 from cut-back 19.

As at December 31, 2019, the inventory balance consisted of 1 million contained gold ounces on surface at Kumtor, of which roughly 73% is expected to be processed in 2020, and 85,246 contained gold ounces and 19.2 million contained pounds of copper in stockpiles at Mount Milligan.

Property, Plant and Equipment

The book value of property, plant and equipment as at December 31, 2019 was $1.7 billion, which compares to $1.9 billion at the end of 2018. The decrease in 2019 of 12% was mainly due to the impairment charge on the Mount Milligan assets recorded in the third quarter of 2019. Capital expenditures in the fourth quarter of 2019 were $95.4 million compared to $60.8 million in the same prior year period, primarily due to increased spending to construct the Öksüt Project and increased capitalized stripping at Kumtor.

Asset Retirement Obligations

The total future asset retirement obligations were estimated by management based on the estimated costs to reclaim the mine sites and facilities and the estimated timing of the costs to be incurred in future periods.

The Company has estimated the net present value of the total asset retirement obligations to be $265.2 million as at December 31, 2019, compared to $212.2 million at the end of 2018, primarily due to a reduction in the discount rates used to calculate the present value of the reclamation costs. The Company does not anticipate any significant costs to be incurred on reclamation until 2027 at the Kumtor Mine, under the assumption that there is no extension of the Kumtor mine life.

In 1998, a reclamation trust fund was established to cover the future costs of reclamation, net of salvage values at the Kumtor Gold Mine. On December 31, 2019, this fund had a balance of $41.0 million.

Debt

As at December 31, 2019, the Company’s $500 million secured revolving credit facility was undrawn (December 31, 2018 – outstanding balance was $111 million).

As at December 31, 2019, the Öksüt Project financing facility had a drawn balance of $77.5 million.

Subsequent to year end, the Company repaid and cancelled its Öksüt Project financing facility, which resulted in the release of $25 million in restricted cash.

In December 2019, the remaining balance of $27.2 million promissory note payable to Caterpillar Financial Services Limited was fully repaid.

Liquidity

The Company believes its cash on hand, cash flow from the Company’s Kumtor, Mount Milligan and Öksüt operations and available capacity in its existing corporate credit facility will be sufficient to satisfy working capital needs, fund its anticipated construction and development activities and meet other liquidity requirements through to the end of 2020.

Cash provided by operating activities

Cash provided by operations increased by 54% in 2019 as a result of higher earnings at Kumtor and Mount Milligan.

Cash used in investing activities

Cash used in investing activities decreased by 12% in 2019 when compared to 2018 due primarily to the acquisition of AuRico in 2018, partially offset by the sale of the Company’s royalty portfolio and disposal of the Mongolian business unit, also in 2018.

Cash used in financing activities

Cash used in financing activities increased by 3% in 2019 when compared to 2018. The increase was mainly on account of higher lease payments, partially offset by lower payments for interest and borrowing costs.

Market Conditions

Gold Price

During the fourth quarter of 2019, the spot gold price fluctuated between a low of $1,454 per ounce and a high of $1,517 per ounce. The average spot gold price for the fourth quarter was $1,483 per ounce, an increase of 21% from the comparative prior year period ($1,229 per ounce). The average gold spot price for 2019 was $1,393 per ounce, an increase of 10% over the average in 2018 ($1,269 per ounce).

Copper Price

The average spot copper price in the fourth quarter of 2019 was $2.68 per pound, a 4% decrease compared to the comparative prior year period ($2.79 per pound). The average copper spot price for 2019 was $2.73 per pound, a decrease of 8% over the average in 2018 ($2.96 per pound).

Molybdenum Price

The average molybdenum price in the fourth quarter of 2019 was $9.65 per pound, a decrease of 20% from the comparative prior year period ($12.05 per pound). The average molybdenum spot price for 2019 was $11.35 per pound, a decrease of 5% over the average in 2018 ($11.94 per pound).

Foreign Exchange

The Company receives its revenues through the sale of gold, copper and molybdenum in U.S. dollars. The Company has operations in Canada, including its corporate head office, the Kyrgyz Republic, Turkey and the United States.

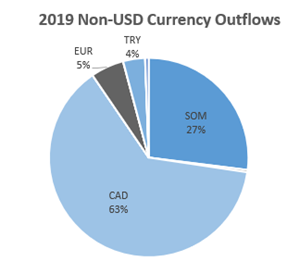

During 2019, the Company incurred combined expenditures (including capital and leases) of approximately $1,266 million. Approximately $644 million of this (51%) was in currencies other than the U.S. dollar. The percentage of Centerra’s non-U.S. Dollar costs by currency was as follows:

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/bd38e06e-625e-4d4b-954d-070bd0f9572e

The net impact of the currency movements in the year ended December 31, 2019, after factoring in the balances in non-USD currencies held at the beginning of the year, was to increase annual costs by $9.0 million (decrease of $14.5 million in the year ended December 31, 2018).

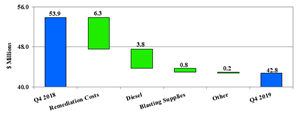

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/2f343bec-adbb-4c1d-9f5d-9a43b838d4bc

USD to CAD

During the fourth quarter of 2019, the spot price of the U.S dollar to Canadian dollar fluctuated between a low of 1.30 and a high of 1.33. The average U.S. dollar to Canadian dollar exchange rate for the fourth quarter of 2019 was 1.32, consistent with the average of the third quarter of 2019 and the fourth quarter of 2018. The Canadian dollar strengthened by 4% from its value as at December 31, 2018 (1.36). As at December 31, 2019, we maintained currency hedges (zero cost collars) on approximately 62% of our Canadian dollar exposure over the next twelve months.

USD to Kyrgyz Som

During the fourth quarter of 2019, the spot price of the U.S. dollar to Kyrgyz som exchange rate fluctuated from 69.6 to 69.9. The average U.S. dollar to Kyrgyz som for the fourth quarter of 2019 was 69.8, consistent with the third quarter of 2019 and minimal movement when compared to the fourth quarter of 2018 (69.6). The Kyrgyz som was relatively consistent to the U.S. dollar as compared to its value at December 31, 2018.

USD to Turkish Lira

The average U.S. dollar to Turkish lira exchange rate for the fourth quarter of 2019 was 5.8, and ranged from 5.7 to 6.0 during the quarter. The Turkish lira weakened by 2% when compared to the third quarter of 2019 (5.7) and 5% when compared to the average of the fourth quarter of 2018 (5.5). The Turkish lira weakened by 9% from its value as at December 31, 2018 (5.3).

Diesel Fuel Prices

After lower prices for a majority of the year when compared to 2018, international benchmarks of crude oil prices, Intercontinental Exchange Brent (“Brent”) and West Texas Intermediate (“WTI”) increased by 13% and 9%, respectively, in the last quarter of 2019.

According to the U.S. Energy Information Administration, the Brent crude oil price averaged $64/bbl. in 2019, $7/bbl. lower than the 2018 average of $71/bbl. As at December 31, 2019 the closing Brent price was $68/bbl., $17/bbl. higher than the price at December 31, 2018 of $51/bbl. WTI crude oil prices averaged $57/bbl. in 2019, $8/bbl. lower than the 2018 average of $65/bbl. As at December 31, 2019 the closing WTI price was $61/bbl., $16/bbl. higher than the price at December 31, 2018 of $45/bbl.

Fuel costs represent a significant cost component for Centerra’s mining operations. Prices for Kumtor diesel fuel in 2019 generally reflected the price movements of Brent crude oil. The purchase price for diesel fuel for Kumtor in 2019 remained unchanged when compared to 2018, averaging $0.52 per litre for the year. Kumtor sources its fuel from Russia either directly or through Kyrgyz distributors. Kumtor’s diesel prices include additional costs such as seasonal premiums for winterizing the diesel fuel and transportation costs from the Russian refineries. Centerra’s diesel hedging program resulted in a $0.7 million realized gain to offset purchasing costs in 2019, compared to $2.2 million realized gain in the same comparative period.