Dundee Precious Metals Announces Updated Mineral Resource Estimate for the Timok Gold Project

TORONTO, Sept. 24, 2018 (GLOBE NEWSWIRE) -- Dundee Precious Metals Inc. (TSX: DPM) (“DPM” or “the Company”) is pleased to announce the results of the updated Mineral Resource estimate for its Timok Gold Project (“Timok”) in Serbia.

Highlights

- Total Indicated Mineral Resources of 46.9 million tonnes at 1.32 g/t Au for 1.996 million ounces

- Includes oxide Indicated Mineral Resources of 21.8 million tonnes at 1.06 g/t Au for 742,000 ounces and transitional Indicated Mineral Resources of 9.2 million tonnes at 1.15 g/t Au for 338,000 ounces

- Column leach test results returned recoveries of up to 94% for oxide mineralization

- Includes a maiden Mineral Resource estimate for the Korkan West deposit of Timok, discovered by DPM in 2016

- Exploration drilling continues to intersect significant intervals of gold mineralization that are outside the new resource model

- Scoping study to be initiated in the fourth quarter of 2018, followed by a potential preliminary economic assessment (“PEA”)

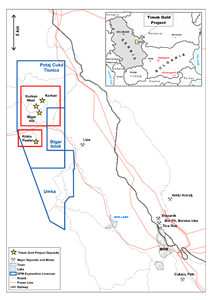

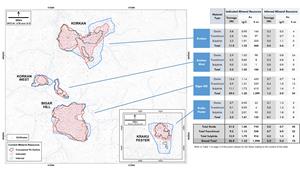

DPM owns 100% of Timok, which is comprised of the Bigar Hill, Korkan, Korkan West, and Kraku Pester deposits. The addition of significant amounts of oxide and transitional mineralization in the Mineral Resource, coupled with encouraging metallurgical test work results, indicates potential to improve the economics of the project relative to the previous PEA released by Avala Resources Ltd. (“Avala”) in July, 2014 (the “2014 PEA”, filed on SEDAR at www.sedar.com), by applying lower cost processing options.

“This updated Mineral Resource is a significant step forward for our Timok gold project,” said Rick Howes, President and CEO. “We are excited to further advance this project within our organic growth pipeline.”

The estimate was prepared by CSA Global (UK) Ltd (“CSA Global”) and is effective as at May 15, 2018.

The Mineral Resource statement for each deposit, and the cut-off grades for each material type, reported using the various cut-off grades, is presented below in Table 1.

Table 1. Mineral Resource Statement for the Timok Gold Project

| Mineral Resource estimates: Timok Gold Project, Serbia, as at May 15, 2018 | |||||||

| Deposit | Indicated Mineral Resource | Inferred Mineral Resource | |||||

| Tonnage (Mt) | Au | Tonnage (Mt) | Au | ||||

| (g/t) | K oz | (g/t) | K oz | ||||

| Bigar Hill | Oxide | 12.4 | 1.14 | 455 | 0.7 | 0.7 | 16 |

| Transitional | 5.9 | 1.21 | 229 | 0.4 | 1.0 | 12 | |

| Sulphide | 11.1 | 1.72 | 615 | 0.1 | 1.6 | 7 | |

| Total | 29.4 | 1.38 | 1,299 | 1.2 | 0.9 | 34 | |

| Korkan | Oxide | 5.8 | 0.90 | 166 | 0.2 | 0.5 | 4 |

| Transitional | 2.8 | 1.06 | 97 | 0.1 | 0.7 | 3 | |

| Sulphide | 3.3 | 1.91 | 205 | 0.0 | 1.1 | 0 | |

| Total | 11.9 | 1.22 | 468 | 0.4 | 0.6 | 7 | |

| Korkan West | Oxide | 2.9 | 1.03 | 98 | 1.0 | 0.8 | 24 |

| Transitional | 0.3 | 0.85 | 8 | 0.2 | 0.8 | 6 | |

| Sulphide | 0.0 | 1.33 | 1 | 0.0 | 0.9 | 0 | |

| Total | 3.2 | 1.02 | 106 | 1.2 | 0.8 | 31 | |

| Kraku Pester | Oxide | 0.7 | 0.95 | 22 | 0.1 | 1.3 | 5 |

| Transitional | 0.1 | 0.95 | 4 | 0.0 | 1.2 | 0 | |

| Sulphide | 1.5 | 2.01 | 95 | 0.0 | 1.8 | 0 | |

| Total | 2.3 | 1.61 | 122 | 0.1 | 1.3 | 6 | |

| Total Oxide | 21.8 | 1.06 | 742 | 2.0 | 0.7 | 48 | |

| Total Transitional | 9.2 | 1.15 | 338 | 0.7 | 0.9 | 22 | |

| Total Sulphide | 15.9 | 1.79 | 916 | 0.2 | 1.5 | 8 | |

| Grand Total | 46.9 | 1.32 | 1,996 | 2.9 | 0.8 | 78 | |

| Notes: | |||||||

| 1. The effective date of the Mineral Resource estimates is May 15, 2018 | |||||||

| 2. Mineral Resources are reported in accordance with CIM guidelines. | |||||||

| 3. A cut-off of 0.20 g/t Au for the oxide material, 0.25 g/t Au for the transitional material, and 0.60 g/t Au for the sulphide material, is applied at Bigar Hill. | |||||||

| 4. A cut-off of 0.20 g/t Au for the oxide material, 0.25 g/t Au for the transitional material, and 0.65 g/t Au for the sulphide material, is applied at Korkan and Korkan West. | |||||||

| 5. A cut-off of 0.35 g/t Au for the oxide material, 0.40 g/t Au for the transitional material, and 1.05 g/t Au for the sulphide material, is applied at Kraku Pester. | |||||||

| 6. Figures have been rounded to the appropriate level of precision for the reporting of Mineral Resources. | |||||||

| 7. Due to rounding, some columns or rows may not compute exactly as shown. | |||||||

| 8. The Mineral Resources are stated as in situ dry tonnes. All figures are in metric tonnes. | |||||||

| 9. The models are reported above surfaces based on conceptual US$1,400 gold price pit shells to support assumptions relating to reasonable prospects of eventual economic extraction. | |||||||

| 10. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. The estimate of Mineral Resources may be materially affected by environmental, permitting, legal, title, taxation, socio-political, marketing, or other relevant issues. | |||||||

See Figure 1 for the location map of Timok and Figure 2 for a plan map of the Mineral Resource estimates by deposit.

The increase in Indicated Mineral Resources compared to the year-end 2017 Mineral Resource estimate disclosed in DPM’s Annual Information Form dated March 28, 2018 (filed on SEDAR at www.sedar.com) is attributable to updated interpretations of the oxide and transitional weathering domains and new metallurgical inputs related to processing oxide and transitional mineralization. The inclusion of oxide and transitional mineralization within the conceptual pit optimisation study has lowered reporting cutoffs, which in turn has increased constrained Mineral Resources. Net changes in Indicated Mineral Resources compared to the 2017 Mineral Resource estimate show an increase of 12 million tonnes and 280,000 ounces of gold. Corresponding percentage increase are 35% in tonnes and 16% in contained ounces of gold.

Recent Background

A previous Mineral Resource estimate formed the basis of the 2014 PEA completed by Avala, which contemplated the flotation and sale of a gold concentrate, but it was determined by DPM that additional optimization and exploration work was required to warrant further study.

In April 2016, DPM acquired the remaining 49.9% minority portion it did not own of Avala, the previous owners of Timok, and other exploration licenses in Serbia. The acquisition was completed through the issuance of 956,329 DPM common shares valued at US$1.6 million.

In late 2016, DPM discovered the Korkan West prospect following a comprehensive technical review integrating new geophysical data to define near resource targets for diamond drilling. The mineralization at the Korkan West prospect was found to be almost entirely comprised of oxide and transitional material types. This new prospect is hosted at the same stratigraphic horizons (S1/S2 sandstones and conglomerates) as found at the Bigar Hill and Korkan prospects.

Subsequent to this discovery, DPM embarked on a series of further technical reviews during 2017 which identified that Timok hosted a much larger proportion of oxide and transitional material than previously recognized which led to the resource update.

Metallurgical Results

In Q1 2018, DPM initiated a testing program to establish the gold recovery potential for the oxidized and transitional mineralization. The test work was conducted by SGS Minerals Services, Lakefield, Ontario. Four drill core composites were taken from Bigar Hill, Korkan and Korkan West deposits for the test program. Each composite was deemed to be representative of the various types of oxide and transitional mineralization found at Timok.

The metallurgical test work, concluded in June 2018, returned encouraging nine-week column leach test results of gold extractions of 94% for the Korkan and Bigar Hill oxide samples, 76% for the Korkan West oxide sample and 68% for the Korkan transitional sample.

Percolation testing on the four composites at various crush sizes indicated that agglomeration would not be required. Reagent consumption was generally low to very low during all phases of test work.

Exploration Update

During 2018, exploration has focused primarily on identifying additional oxide and transitional gold resources near the Bigar Hill, Korkan, and Korkan West deposits within the Potoj Čuka Tisnica and Bigar Istok exploration licenses. Approximately 8,000m of this year’s 11,500m diamond drilling program has been completed and include the following highlights from holes that are outside the new resource model (using 0.25 g/t gold cut-off grade and 3 metre maximum internal dilution):

- 39 metres grading 1.84 g/t gold between 246 to 285 metres downhole (oxide) following a 7 metre interval grading 1.68 g/t between 229 to 236 metres downhole (transitional) in hole BHDD094 located about 70 metres NE of current interpreted extents of mineralization.

- 13 metres grading 6.43 g/t gold between 96 and 109 metres downhole (transitional) in hole BIDD079, one of a series of holes to extend the Bigar Hill deposit to the west.

Plan Forward

Based on the updated Mineral Resource estimate, the Company plans to initiate a scoping study in the fourth quarter of 2018 for Timok and, based on the results of the scoping study, expects to release a PEA in the first quarter of 2019. These studies will focus on the initial economics of the oxide and transitional material to be constrained in a separate open pit shell excluding the sulphides, as well as the high level potential for subsequent development of the sulphide resource. Development of a permitting and approvals plan incorporating the ESIA process and approvals as well as all additional licensing (major permits and authorizations) requirements will also be initiated in the fourth quarter. Exploration plans for 2019 are being developed to identify additional high quality targets to expand the near surface oxide resources.

Mineral Resource Estimate

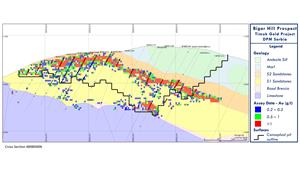

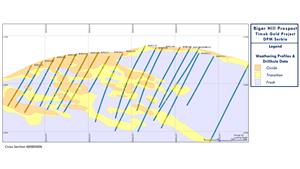

The drill hole database, consisting of 1,366 drill holes for 274,370m of drilling, was closed off as of May 15, 2018. Mineralization domains were built at a 0.1 g/t cutoff and 3m downhole width, which sufficiently constrains the broad mineralization trends and is appropriate considering the open pit mining method to be employed at Timok. A detailed geologic model for each prospect was built to aid in contouring mineralized domains, which are characterized by a strong stratigraphic control (see Figure 3). Based on 3,930 five-metre composite, bottle roll assays and geologic re-logging data, weathering profiles for the oxide, transitional and fresh portions of the mineralization were built in Leapfrog® Geo Implicit Modelling software using an indicator interpolation approach (see Figure 4).

Mineral Resources at the Timok gold project were estimated using Ordinary Kriging with search ellipse orientations guided by the Dynamic Anisotropy function in Datamine StudioRMTM. Based on Kriging Neighbourhood analysis, a block panel size of 20m x 20m x 10m was deemed optimum for the deposits. Recoverable resources were estimated using Uniform Conditioning (UC), which is a technique appropriate for the gradational grade profile and wide data spacing observed at Timok. SMU sized blocks (5mN x 5mE x 5mRL) were kriged and the resultant SMU blocks ranked by grade proportion. Grades were assigned to SMUs based on the estimated ranking, through a process called Localized Uniform Conditioning (LUC). Bulk density was estimated by IDW2 (Inverse Distance Weighting).

The Indicated Mineral Resource category was assigned to blocks estimated in search pass 1, with a slope of regression statistic of at least 0.75, using at least 10 composites to estimate and are within the 40m x 40m drill spacing. Blocks with an estimated gold grade but falling outside the Indicated Mineral Resources criteria were assumed to be of lower confidence and classified as Inferred Mineral Resources.

Mineral Resources are reported constrained within conceptual pit optimization shells for each deposit, for the purposes of demonstrating reasonable chances of eventual economic extraction, required for Mineral Resource disclosure. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. The open-pit shells have been determined via consideration of various cutoff grades for material types that were calculated based upon, among other things, the material type, haulage distance and recoveries derived from metallurgical test work.

Results from the metallurgical test program were discounted to provide inputs into the optimisation study. The table below shows the steps to generate the discounted recoveries.

| Sample ID | Crush Size (mm) | Column Leach Recovery | Correction Factor | Corrected Recovery | CIC/ Goldroom | %Au Recovery | |

| % Au | % | to Dore | |||||

| Korkan Oxide | -12.5 | 94.4 | 2 | 92.4 | 99 | % | 91.5 |

| Korkan Transitional | -12.5 | 75.0 | 5 | 70.0 | 99 | % | 69.3 |

| Bigar Hill Oxide | -12.5 | 94.2 | 2 | 92.2 | 99 | % | 91.3 |

| Korkan West Oxide | -12.5 | 75.5 | 2 | 73.5 | 99 | % | 72.8 |

The oxide column test recoveries are discounted by 2% to reflect scale up from laboratory column scale to industrial scale performance, which considers losses and percolation inefficiencies. The Korkan transitional column leach test was stopped prematurely after 63 days, despite continued leaching of Au. Based on regression analysis, the predicted gold leach recovery after 90 days of leaching is 75%. This figure was discounted by a 5% correction factor, since the gold leach recovery was extrapolated above the final column leach test recovery. Further testing will be carried out to verify the ultimate leach recovery for the Korkan transitional ore.

The recovery value derived from the Korkan transitional column leach was assigned to the Bigar Hill, Kraku Pester and Korkan West transitional material. This is based on the observation that the 5m composite bottle roll assays and transitional mineralization characteristics are consistent within each of the prospects. The Korkan West oxide recovery figure was applied to the Kraku Pester oxide material based on comparable mineralization styles and review of the 5m composite bottle roll assays from this prospect.

A full list of parameters used in the conceptual pit optimization study are detailed below.

| Units | Bigar Hill | Korkan | Korkan West | Kraku Pester | |||

| Costs | Mining Cost | Waste | $/t mined | 2.39 | 2.58 | 2.39 | 2.45 |

| Ore (Oxide and Transitional) | $/t ore | 2.39 | 2.58 | 2.39 | 2.45 | ||

| Ore (Sulphide) | $/t ore | 3.09 | 3.28 | 3.09 | 3.15 | ||

| Incremental cost per 10m bench | $/t mined | 0.045 from 530RL | 0.045 from 560 RL | 0.045 from 560 RL | 0.045 from 480 RL | ||

| Rehabilitation | $/t mined | 0.09 | 0.09 | 0.09 | 0.09 | ||

| Ore haulage from Kraku Pester | $/t ore | - | - | - | 3.5 | ||

| Processing & Admin | Ore (Oxide and Transitional) | $/t ore | 6.22 | ||||

| Ore (Sulphide) | $/t ore | 12.81 | |||||

| Off-Site Costs | Ore (Oxide and Transitional) | $/oz | 5 | ||||

| Total concentrate and smelter cost (Sulphide) | $/oz | 200 | |||||

| Royalty | % | 5 | |||||

| Parameters | Mining Parameters | Mining Recovery | % | 95 | |||

| Dilution | % | 0.0 | |||||

| Au Processing Recovery | Ore (Oxide) | % | 91.3 | 91.5 | 72.8 | 72.8 | |

| Ore (Transitional) | % | 69.3 | 69.3 | 69.3 | 69.3 | ||

| Ore (Sulphide) | % | 70 | 65 | 65 | 50 | ||

| Overall Slope Angle | Oxide Zone | deg. | 45 | ||||

| Transitional and Sulphide | deg. | 52.5 | |||||

| Revenue | Price of gold | $/oz | 1,250(RF=1).Pit shell at 1,400 | ||||

| Payable for Oxide and Transitional | % | 99 | |||||

| Payable for Sulphide | % | 100 | |||||

| Analysis | Discount Rate | % | 7.50 | ||||

| Grams in a Troy Ounce | 31.1035 | ||||||

| Processing Rate | Mtpa | 2.0 | |||||

Technical Information

The Mineral Resource estimates and other scientific and technical information contained in this news release were prepared by CSA Global, in accordance with the Canadian regulatory requirements set out in National Instrument 43-101, Standards of Disclosure for Mineral Projects (“NI 43-101”), and has been reviewed and approved by, as it relates to Mineral Resources, Maria O’Connor, BSc, MAIG, Principal Resource Geologist of CSA Global, as it relates to the Metallurgy, Gary Patrick BSc, MAusIMM (CP) Senior Associate Metallurgist on behalf of CSA Global, and by David Muir, BSc (Hons) Geology, Data Manager (CSA Global), as it relates to sampling, drilling and QAQC. Maria O’Connor, Gary Patrick and David Muir are all independent Qualified Persons (“QP”), as defined under NI 43-101.

Ross Overall, Corporate Senior Resource Geologist of DPM, who is a QP and not independent of the Company, has reviewed and approved the contents of this release. A NI 43-101 compliant technical report, in respect of the Mineral Resource estimates disclosed herein, will be filed on SEDAR within 45 days of this news release.

The Mineral Resource and Mineral Reserve estimates contained herein may be subject to legal, political, environmental or other risks that could materially affect the potential development of such Mineral Resources. See the Technical Report for more information with respect to the key assumptions, parameters, methods and risks of determination associated with the foregoing.

Cautionary note to U.S. investors concerning estimates of Mineral Resources

These estimates have been prepared in accordance with the requirements of Canadian securities laws, which differ from the requirements of U.S. securities laws. The terms “mineral resource”, “measured mineral resource”, “indicated mineral resource” and “inferred mineral resource” are defined in NI 43-101 and recognized by Canadian securities laws but are not defined terms under the U.S. Securities and Exchange Commission (“SEC”) Guide 7 (“SEC Guide 7”) or recognized under U.S. securities laws. U.S. investors are cautioned not to assume that any part or all of mineral deposits in these categories will ever be upgraded to mineral reserves. “Inferred mineral resources” have a great amount of uncertainty as to their existence, and great uncertainty as to their economic and legal feasibility. It cannot be assumed that all or any part of an “inferred mineral resource” will ever be upgraded to a higher category. Under Canadian securities laws, estimates of “inferred mineral resources” may not form the basis of feasibility or pre-feasibility studies. U.S. investors are cautioned not to assume that all or any part of an inferred mineral resource exists or is economically or legally mineable. Accordingly, these mineral resource estimates and related information may not be comparable to similar information made public by U.S. companies subject to the reporting and disclosure requirements under the U.S. federal securities laws and the rules and regulations thereunder, including SEC Guide 7.

About Dundee Precious Metals

Dundee Precious Metals Inc. is a Canadian based, international gold mining company engaged in the acquisition of mineral properties, exploration, development, mining and processing of precious metals. The Company's operating assets include the Chelopech operation, which produces a copper concentrate containing gold and silver and a pyrite concentrate containing gold, located east of Sofia, Bulgaria; and the Tsumeb smelter, a complex copper concentrate processing facility located in Namibia. DPM also holds interests in a number of developing gold and exploration properties located in Bulgaria, including the Krumovgrad gold project, which started construction in the fourth quarter of 2016 and is expected to commence production in the fourth quarter of 2018, Canada, Serbia, and its 10.2% interest in Sabina Gold & Silver Corp.

Cautionary Note Regarding Forward Looking Statements

This press release contains “forward looking statements” or “forward looking information” (collectively, “Forward Looking Statements”) that involve a number of risks and uncertainties. Statements that constitute Forward looking statements include, but are not limited to, certain statements with respect to commodity prices; the estimation of Mineral Reserves and Mineral Resources and the realization of such mineral estimates; results of economic studies; success of exploration activities. Forward Looking Statements are statements that are not historical facts and are generally, but not always, identified by the use of forward looking terminology such as “plans”, “expects”, or “does not expect”, “is expected”, “budget”, “scheduled”, “estimates”, “forecasts”, “outlook”, “intends”, “anticipates”, or “does not anticipate”, or “believes”, or variations of such words and phrases or that state that certain actions, events or results “may”, “could”, “would”, “might” or “will” be taken, occur or be achieved. Forward Looking Statements are based on certain key assumptions and the opinions and estimates of management and Qualified Persons (in the case of technical and scientific information), as of the date such statements are made, and they involve known and unknown risks, uncertainties and other factors which may cause the actual results, performance or achievements of the Company to be materially different from any other future results, performance or achievements expressed or implied by the Forward Looking Statements. In addition to factors already discussed in this document, such factors include, among others: the uncertainties with respect to the actual results of current exploration activities; conclusions of economic evaluations and economic studies; changes in project parameters as plans continue to be refined; possible variations in ore grade or recovery rates; delays in obtaining governmental approvals or financing or in the completion of development or construction activities, social and non-governmental organizations (“NGO”) opposition to mining projects and smelting operations; uncertainties inherent with conducting business in foreign jurisdictions where corruption, civil unrest, political instability and uncertainties with the rule of law may impact the Company’s activities; fluctuations in metal and acid prices, toll rates and foreign exchange rates; unanticipated title disputes; claims or litigation; limitation on insurance coverage; as well as those risk factors discussed or referred to in the Company’s MD&A under the heading “Risks and Uncertainties” and under the heading “Cautionary Note Regarding Forward Looking Statements” which include further details on material assumptions used to develop such Forward Looking Statements and material risk factors that could cause actual results to differ materially from Forward Looking Statements, and other documents (including without limitation the Company’s most recent Annual Information Form) filed from time to time with the securities regulatory authorities in all provinces and territories of Canada and available on SEDAR at www.sedar.com. Although the Company has attempted to identify important factors that could cause actual actions, events or results to differ materially from those described in Forward Looking Statements, there may be other factors that cause actions, events or results not to be anticipated, estimated or intended. There can be no assurance that Forward Looking Statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Other than as it may be required by law, the Company undertakes no obligation to update Forward Looking Statements if circumstances or management’s estimates or opinions should change. Accordingly, readers are cautioned not to place undue reliance on Forward Looking Statements.

For further information, please contact:

DUNDEE PRECIOUS METALS INC.

| Rick Howes President and Chief Executive Officer Tel: (416) 365-2836 rhowes@dundeeprecious.com | |

Janet Reid

Manager, Investor Relations

Tel: (416) 365-2549

jreid@dundeeprecious.com

Photos accompanying this announcement are available at

http://www.globenewswire.com/NewsRoom/AttachmentNg/7df48c3c-de8d-4df0-9828-0d9859679a3b

http://www.globenewswire.com/NewsRoom/AttachmentNg/8c831e03-89bb-46ee-893e-924e66c1e95e

http://www.globenewswire.com/NewsRoom/AttachmentNg/5a87a2d7-1079-4977-bbc6-e83b2c0ff90a

http://www.globenewswire.com/NewsRoom/AttachmentNg/53fab313-d59e-4a68-9273-efd10f55e2e2