First Quantum Minerals Reports Third Quarter 2024 Results

(In United States dollars, except where noted otherwise)

TORONTO, Oct. 22, 2024 (GLOBE NEWSWIRE) -- First Quantum Minerals Ltd. (“First Quantum” or the "Company”) (TSX: FM) today reports results for the three months ended September 30, 2024 (“Q3 2024” or the "third quarter") of net earnings attributable to shareholders of the Company of $108 million ($0.13 earnings per share) and adjusted earnings1 of $119 million ($0.14 adjusted earnings per share2).

“While it is pleasing to see continued strong operational performance from the Zambian operations during the third quarter, this was marred by a tragic accident in September resulting in the death of a colleague at Kansanshi. We continue to support the family and we remain committed to ensure the safety of our colleagues across the business. While ZESCO power restrictions continue, our Zambian team's proactive actions have resulted in minimal production impacts. The S3 Expansion continues to make good progress for production in the second half of 2025,” commented Tristan Pascall, Chief Executive Officer of First Quantum. “In Panama, we continue to engage with local authorities for the approval of the Preservation and Safe Management program for Cobre Panamá. With Cobre Panamá remaining in a state of preservation and safe management and the ongoing capital expenditures related to the S3 Expansion, we are continuing efforts to maintain the strength of the balance sheet and, as such, additional hedges were added during the quarter.”

Q3 2024 SUMMARY

In Q3 2024, First Quantum reported gross profit of $456 million, EBITDA1 of $520 million, net earnings attributable to shareholders of $0.13 per share, and adjusted earnings per share2 of $0.14. Relative to the second quarter of 2024 (“Q2 2024”), third quarter financial results improved due to higher copper and gold sales volumes along with stronger realized gold prices. Total copper production for the third quarter was 116,088 tonnes, a 13% increase from Q2 2024. Copper C1 cash cost3 was $1.57 per lb in the third quarter, a decrease of 9% quarter-over-quarter.

There were a number of developments during the third quarter that are also detailed in this news release:

- 2024 Guidance for copper production has narrowed to the top end of previous guidance, while gold production guidance has increased. Copper C1 cash cost3 guidance has narrowed to the low end of previous guidance.

- During the quarter, the Company entered into additional derivative contracts. More than half of planned production and sales remains exposed to spot copper prices through the period until the end of 2025.

- On October 15, 2024, FQM Trident signed a $425 million unsecured term loan facility with a maturity date of September 2028 to replace the previous Trident facility that was scheduled to mature in December 2025.

- While Zambia’s energy crisis persisted in the third quarter, operational adjustments minimized the effect on copper production. Minimal operational interruptions are expected heading into the fourth quarter of 2024.

- As part of the ongoing board renewal program, the Company is pleased to announce the appointments of Ms. Juanita Montalvo and Mr. Hanjun ("Kevin") Xia to its Board of Directors with immediate effect.

_______________________

1 EBITDA and adjusted earnings (loss) are non-GAAP financial measures. These measures do not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

2 Adjusted earnings (loss) per share is a non-GAAP ratio which does not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

3 C1 cash cost (C1) is a non-GAAP ratio, which does not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”

Q3 2024 OPERATIONAL HIGHLIGHTS

Total copper production for the third quarter was 116,088 tonnes, a 13% increase from Q2 2024 as a result of higher production at the Zambian operations. While Zambia’s energy crisis persisted in the third quarter, First Quantum’s proactive sourcing of supplementary power minimized disruptions, allowing normal operations to continue for most of the quarter. The impact of higher costs associated with the imported power was mitigated by strong gold by-product credits during the quarter. Copper C1 cash cost1 was $0.16 per lb lower quarter-over-quarter at $1.57 per lb, reflecting higher copper production, along with lower fuel costs. Copper sales volumes totalled 112,094 tonnes, approximately 3,994 tonnes lower than production due to the timing of shipments.

- Kansanshi reported the highest quarterly copper production since the fourth quarter of 2021. Copper production of 49,810 tonnes in Q3 2024 was 8,303 tonnes higher than the previous quarter as continued mining discipline resulted in higher feed grades on the mixed and oxide circuits. During the quarter, the sulphide and mixed mills were swapped to increase the throughput of mixed material which contained higher grades. Gold production of 31,659 ounces for the third quarter of 2024 was the highest quarterly production since the first quarter of 2022. Copper C1 cash cost1 of $1.29 per lb was $0.22 lower quarter-over-quarter due to improved production volumes. Production guidance for 2024 has increased to 155,000 - 165,000 tonnes of copper from 130,000 - 150,000 tonnes while gold production guidance has increased to 90,000 - 100,000 ounces from 65,000 - 75,000 ounces. A swap of the mixed and sulphide mills will continue in the fourth quarter in order to maximize mixed grade through the mills. Fourth quarter gold production is expected to be lower than the third quarter due to lower grades.

- Sentinel reported copper production of 58,412 tonnes in Q3 2024, approximately 4,817 tonnes higher than the previous quarter as improved throughput levels benefitted from better performance of the in-pit crushers as well as improved fragmentation of the ore. Copper C1 cash cost1 of $1.86 per lb was lower than the preceding quarter as a result of higher production volumes. Copper production guidance for 2024 has narrowed to 220,000 - 230,000 tonnes from 220,000 - 250,000 tonnes. Mining performance and throughput is expected to further improve over the remainder of the year with the ongoing development of Stage 3 (Western Cut-back) which will enable improved mining productivities due to the increased availability of softer material on shorter haul cycles. The improvement in fragmentation experienced in the third quarter that led to improved crushing and milling rates is expected to continue for the remainder of the year. The development of the Stage 1 sump is on schedule to be completed during October 2024 along with other site works in preparation for the upcoming wet season.

- Enterprise had its first full quarter of commercial production, producing 4,827 tonnes of nickel during the third quarter, a decrease from 6,147 tonnes in Q2 2024. The plant has been stable and achieved record throughput in August 2024. The plant was shut down for the last nine days of September due to power supply restrictions in order to prioritize power for the copper circuit. Plant operations resumed in October. Production guidance for 2024 for Enterprise remains unchanged at 17,000 – 20,000 contained tonnes of nickel. Good progress has been made in preparation for the wet season and securing of the south wall. The focus for the remainder of the year will be on increasing mobile equipment reliability through supporting the contractor uplift maintenance practices in order to increase mining volumes.

- Cobre Panamá remains in a phase of preservation and safe management ("P&SM") with production halted and production guidance suspended. During the quarter, the process plant assets inspection frequency was changed from 28 to 56 days, while the equipment start-up frequency remains unchanged at 14 days to ensure equipment preservation through dynamic lubrication and monitoring asset conditions. All the major ultra-class mobile equipment is in a maintenance cycle that adheres to the original equipment manufacturer’s long-term storage recommendations and includes periodic inspections as well as scheduled startups. In addition to asset preservation, a key focus continues to be on maintaining the environmental stability for all areas of the site and compliance with the environmental and social impact study for the project, which remains in force. The costs for the P&SM program in the third quarter were approximately $13 million per month, which included labour, maintenance spares, contractor’s services, electricity, and other general expenses. During the quarter, activities on site were further curtailed with reduction in active equipment for the tailings management facility and open pit maintenance. For the remainder of the year, P&SM expenses are expected to be $11 - $13 million per month, depending on the level of environmental stability and asset integrity programs. The Company is actively managing the P&SM costs of Cobre Panamá and will adjust the level of employment and cost of these activities according to the conditions on the ground in Panama. Approximately 121 thousand dry metric tonnes of copper concentrate remain onsite.

_______________________

1 C1 cash cost (C1) is a non-GAAP ratio, which does not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”

FINANCIAL HIGHLIGHTS

Financial results continue to be impacted by Cobre Panamá being in a phase of P&SM, however, the third quarter benefitted from higher copper and gold sales volumes along with stronger gold prices.

- Gross profit for the third quarter of $456 million was $123 million higher than Q2 2024, while EBITDA1 of $520 million for the same period was $184 million higher.

- Cash flows from operating activities of $260 million ($0.31 per share2) for the quarter were $137 million lower than Q2 2024.

- Net debt3 increased by $154 million during the quarter, attributable mainly to planned capital expenditures at Kansanshi and an increase in net working capital, taking the net debt3 level to $5,591 million, with total debt at $6,284 million as at September 30, 2024.

_______________________

1 EBITDA is a non-GAAP financial measure which does not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

2 Cash flows from operating activities per share is a non-GAAP ratio, which does not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

3 Net debt is a supplementary financial measure which does not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

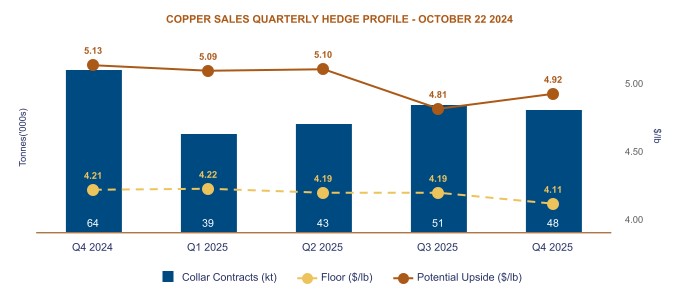

HEDGING PROGRAM

During the quarter, and consistent with the approach outlined in the second quarter results of 2024, the Company entered into derivative contracts, in the form of additional unmargined zero cost copper collars, as protection from downside price movements, financed by selling price upside beyond certain levels on a matched portion of production. More than half of planned production and sales remains exposed to spot copper prices through the period until the end of 2025.

At October 22, 2024, the Company had zero cost copper collar contracts for 245,400 tonnes at weighted average prices of $4.18 per lb to $5.01 per lb outstanding with maturities to December 2025.

FQM TRIDENT FACILITY

At Trident, on October 15, 2024, FQM Trident signed a $425 million unsecured term loan facility (the “FQM Trident Facility”) with a maturity date of September 2028 to replace the previous Trident facility that was scheduled to mature in December 2025. Repayments on the FQM Trident Facility will commence in March 2026 and are due every six months thereafter. This action is in line with the Company’s prudent management of its debt maturities.

CONSOLIDATED FINANCIAL HIGHLIGHTS

| QUARTERLY | |||||||||

| Q3 2024 | Q2 2024 | Q3 2023 | |||||||

| Sales revenues | 1,279 | 1,231 | 2,029 | ||||||

| Gross profit | 456 | 333 | 660 | ||||||

| Net earnings (loss) attributable to shareholders of the Company | 108 | (46 | ) | 325 | |||||

| Basic earnings (loss) per share | $0.13 | ($0.06 | ) | $0.47 | |||||

| Diluted earnings (loss) per share | $0.13 | ($0.06 | ) | $0.47 | |||||

| Cash flows from operating activities3 | 260 | 397 | 594 | ||||||

| Net debt1 | 5,591 | 5,437 | 5,637 | ||||||

| EBITDA1,2 | 520 | 336 | 969 | ||||||

| Adjusted earnings (loss)1 | 119 | (13 | ) | 359 | |||||

| Adjusted earnings (loss) per share3 | $0.14 | ($0.02 | ) | $0.52 | |||||

| Cash cost of copper production excluding Cobre Panamá (C1) (per lb)3,4 | $1.57 | $1.73 | $1.66 | ||||||

| Total cost of copper production excluding Cobre Panamá (C3) (per lb)3,4 | $2.54 | $2.83 | $2.60 | ||||||

| Copper all-in sustaining cost excluding Cobre Panamá (AISC) (per lb)3,4 | $2.35 | $2.71 | $2.54 | ||||||

| Cash cost of copper production (C1) (per lb)3,4 | $1.57 | $1.73 | $1.42 | ||||||

| Total cost of copper production (C3) (per lb)3,4 | $2.59 | $2.87 | $2.29 | ||||||

| Copper all-in sustaining cost (AISC) (per lb)3,4 | $2.42 | $2.82 | $2.02 | ||||||

| Realized copper price (per lb)3 | $4.24 | $4.39 | $3.70 | ||||||

| Net earnings (loss) attributable to shareholders of the Company | 108 | (46 | ) | 325 | |||||

| Adjustments attributable to shareholders of the Company: | |||||||||

| Adjustment for expected phasing of Zambian value-added tax (“VAT”) | (17 | ) | (27 | ) | (15 | ) | |||

| Loss on redemption of debt | – | – | – | ||||||

| Total adjustments to EBITDA1 excluding depreciation2 | 32 | 71 | 61 | ||||||

| Tax adjustments | – | 6 | (12 | ) | |||||

| Minority interest adjustments | (4 | ) | (17 | ) | – | ||||

| Adjusted earnings (loss)1 | 119 | (13 | ) | 359 | |||||

1 EBITDA and adjusted earnings (loss) are non-GAAP financial measures, and net debt is a supplementary financial measure. These measures do not have a standardized meaning under IFRS and might not be comparable to similar financial measures disclosed by other issuers. Adjusted earnings (loss) have been adjusted to exclude items from the corresponding IFRS measure, net earnings (loss) attributable to shareholders of the Company, which are not considered by management to be reflective of underlying performance. The Company has disclosed these measures to assist with the understanding of results and to provide further financial information about the results to investors and may not be comparable to similar financial measures disclosed by other issuers. The use of adjusted earnings (loss) and EBITDA represents the Company’s adjusted earnings (loss) metrics. See “Regulatory Disclosures”.

2 Adjustments to EBITDA in 2024 principally relate to impairment expense, restructuring expense and foreign exchange losses (2023 - royalties, restructuring expenses and foreign exchange losses).

3 Adjusted earnings (loss) per share, realized metal prices, copper all-in sustaining cost (copper AISC), copper C1 cash cost (copper C1) and total cost of copper (copper C3) are non-GAAP ratios, which do not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

4 Excludes the sale of copper anode produced from third-party concentrate purchased at Kansanshi. Sales of copper anode attributable to third-party concentrate purchases were 7,537 tonnes for the three months ended September 30, 2024, (11,228 tonnes for the three months ended September 30, 2023).

CONSOLIDATED OPERATING HIGHLIGHTS

| QUARTERLY | ||||||

| Q3 2024 | Q2 2024 | Q3 2023 | ||||

| Copper production (tonnes)1 | 116,088 | 102,709 | 221,550 | |||

| Cobre Panamá | – | – | 112,734 | |||

| Kansanshi | 49,810 | 41,507 | 39,600 | |||

| Sentinel | 58,412 | 53,595 | 63,805 | |||

| Other Sites | 7,866 | 7,607 | 5,411 | |||

| Copper sales (tonnes)2 | 112,094 | 94,628 | 218,946 | |||

| Cobre Panamá | – | – | 113,616 | |||

| Kansanshi2 | 49,131 | 36,332 | 41,820 | |||

| Sentinel | 53,662 | 51,113 | 58,600 | |||

| Other Sites | 9,301 | 7,183 | 4,910 | |||

| Gold production (ounces) | 41,006 | 32,266 | 73,125 | |||

| Cobre Panamá | – | – | 45,996 | |||

| Kansanshi | 31,659 | 23,575 | 19,946 | |||

| Guelb Moghrein | 8,621 | 8,144 | 6,765 | |||

| Other sites | 726 | 547 | 418 | |||

| Gold sales (ounces)3 | 43,371 | 37,140 | 77,106 | |||

| Cobre Panamá | – | – | 45,959 | |||

| Kansanshi | 34,186 | 28,860 | 23,704 | |||

| Guelb Moghrein | 8,382 | 7,572 | 7,292 | |||

| Other sites | 803 | 708 | 151 | |||

| Nickel production (contained tonnes)4 | 4,827 | 7,400 | 7,046 | |||

| Nickel sales (contained tonnes)5 | 4,598 | 7,645 | 5,749 | |||

| Cash cost of copper production (C1) (per lb)2,6 | $1.57 | $1.73 | $1.42 | |||

| C1 (per lb) excluding Cobre Panamá 2,6 | $1.57 | $1.73 | $1.66 | |||

| Total cost of copper production (C3) (per lb)2,6 | $2.59 | $2.87 | $2.29 | |||

| Copper all-in sustaining cost (AISC) (per lb)2,6 | $2.42 | $2.82 | $2.02 | |||

| AISC (per lb) excluding Cobre Panamá 2,6 | $2.35 | $2.71 | $2.54 | |||

1 Production is presented on a contained basis, and is presented prior to processing through the Kansanshi smelter.

2 Sales exclude the sale of copper anode produced from third-party concentrate purchased at Kansanshi. Sales of copper anode attributable to third-party concentrate purchases were 7,537 tonnes for the three months ended September 30, 2024, respectively, (11,228 tonnes for the three months ended September 30, 2023).

3 Excludes refinery-backed gold credits purchased and delivered under the precious metal streaming arrangement (see “Precious Metal Stream Arrangement”).

4 Nickel production includes 3,875 tonnes of pre-commercial production from Enterprise for the three months ended June 30, 2024, which is not included in earnings (loss) or C1, C3 and AISC calculations. (1,556 tonnes for the three months ended September 30, 2023).

5 Nickel sales (contained tonnes) includes 1,388 tonnes of of pre-commercial sales from Enterprise for the three months ended June 2024. (97 tonnes for the three months ended September 30, 2023.

6 Copper all-in sustaining cost (copper AISC), copper C1 cash cost (copper C1), and total cost of copper (copper C3) are non-GAAP ratios, which do not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

REALIZED METAL PRICES1

| QUARTERLY | |||||||||

| Q3 2024 | Q2 2024 | Q3 2023 | |||||||

| Average LME copper cash price (per lb) | $4.18 | $4.42 | $3.79 | ||||||

| Realized copper price1 (per lb) | $4.24 | $4.39 | $3.70 | ||||||

| Treatment/refining charges (“TC/RC”) (per lb) | ($0.06 | ) | ($0.06 | ) | ($0.15 | ) | |||

| Freight charges (per lb) | ($0.03 | ) | ($0.05 | ) | ($0.02 | ) | |||

| Net realized copper price1 (per lb) | $4.15 | $4.28 | $3.53 | ||||||

| Average LBMA cash price (per oz) | $2,474 | $2,338 | $1,929 | ||||||

| Net realized gold price1,2 (per oz) | $2,383 | $2,207 | $1,764 | ||||||

| Average LME nickel cash price (per lb) | $7.37 | $8.35 | $9.23 | ||||||

| Net realized nickel price1 (per lb) | $7.35 | $7.86 | $8.96 | ||||||

1 Realized metal prices are a non-GAAP ratio, do not have standardized meanings under IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures” for further information.

2 Excludes gold revenues recognized under the precious metal stream arrangement.

2024 GUIDANCE

Guidance is based on a number of assumptions and estimates as of September 30, 2024, including among other things, assumptions about metal prices and anticipated costs and expenditures. Guidance involves estimates of known and unknown risks, uncertainties and other factors, which may cause the actual results to be materially different.

Guidance has been updated to reflect performance year-to-date and the outlook for the remainder of the year. Copper production guidance has narrowed to a range of 400,000 – 420,000 tonnes from 370,000 – 420,000 tonnes. Strong performance from Kansanshi, Guelb Moghrein and Cayeli has resulted in an increase in copper production guidance for these operations. Sentinel guidance range has been narrowed with the upper end reduced based on performance to date. Gold production guidance has increased to 120,000 – 135,000 ounces from 95,000 – 115,000 ounces to reflect higher grades experienced to date at Kansanshi. Nickel production guidance remains unchanged.

Copper unit cost guidance has been narrowed for both C11 and AISC1 to reflect performance to date, coupled with a favourable Zambian kwacha/US dollar exchange rate and strong by-product credits, partially offset by increased Zambian electricity costs. Guidance does not include any P&SM costs with respect to Cobre Panamá. C1 cash costs1 guidance assumes a gold price of $2,500 per ounce for the remainder of the year, an average Brent crude oil price of $85 per barrel and a Zambian kwacha/US dollar exchange rate of 25.

Previous nickel unit cash cost guidance for 2024 was for Ravensthorpe only and was withdrawn in the second quarter. There is no guidance provided for Enterprise as operations ramp up this year. Care and maintenance costs for Ravensthorpe are expected to be approximately $2 million per month in the fourth quarter.

Guidance for total capital expenditure remains unchanged at $1,250 - $1,400 million.

PRODUCTION GUIDANCE

| 000’s | 2024 Previous Guidance | 2024 Updated Guidance |

| Copper (tonnes) | 370 – 420 | 400 – 420 |

| Gold (ounces) | 95 – 115 | 120 – 135 |

| Nickel (contained tonnes) | 22 – 25 | 22 – 25 |

_______________________

1 Realized metal prices, C1 cash cost (C1), and all-in sustaining cost (AISC) are non-GAAP ratios which do not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

PRODUCTION GUIDANCE BY OPERATION1

| Copper production guidance (000’s tonnes) | 2024 Previous Guidance | 2024 Updated Guidance |

| Kansanshi | 130 – 150 | 155 – 165 |

| Trident - Sentinel | 220 – 250 | 220 – 230 |

| Other sites | 20 | 25 |

| Gold production guidance (000’s ounces) | ||

| Kansanshi | 65 – 75 | 90 – 100 |

| Guelb Moghrein | 28 – 38 | 28 – 33 |

| Other sites | 2 | 2 |

| Nickel production guidance (000’s contained tonnes) | ||

| Ravensthorpe | 5 | 5 |

| Trident - Enterprise | 17 – 20 | 17 – 20 |

1 Production is stated on a 100% basis as the Company consolidates all operations.

CASH COST1 AND ALL-IN SUSTAINING COST1

| Total Copper | 2024 Previous Guidance | 2024 Updated Guidance |

| C1 (per lb)1 | $1.80 – $2.05 | $1.80 – $1.95 |

| AISC (per lb)1 | $2.70 – $3.00 | $2.70 – $2.90 |

1 C1 cash cost (C1), and all-in sustaining cost (AISC) are non-GAAP ratios which do not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

PURCHASE AND DEPOSITS ON PROPERTY, PLANT & EQUIPMENT

| 2024 | |

| Capitalized stripping1 | 180 – 230 |

| Sustaining capital1 | 260 – 290 |

| Project capital1 | 810 – 880 |

| Total capital expenditure | 1,250 – 1,400 |

1 Capitalized stripping, sustaining capital and project capital are non-GAAP financial measures which do not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

ZAMBIA POWER UPDATE

During the quarter, Zambia’s energy crisis persisted due to the El Niño-induced drought, which has significantly reduced the country’s hydropower generation. Despite these challenges, First Quantum’s proactive sourcing of supplementary power minimized disruptions, allowing normal operations to continue for most of the quarter.

In late September 2024, planned maintenance work on a 150 MW thermal generation unit at Maamba Collieries led to a nine-day, 30% power reduction imposed on Zambian Electricity Supply Corporation Limited (“ZESCO”)-supplied power to the Company’s Zambian mine sites. However, the Company’s supplementary sourcing strategy limited the actual impact on its Zambian mine sites to a 10% reduction in maximum power availability during the 9-day period. Operational adjustments, including rescheduling maintenance and prioritizing critical activities, minimized the effect on copper production.

By the end of the quarter, with the restoration of 150 MW from the thermal generation unit and increased ZESCO imports from South Africa, power availability at the Company’s Zambian mine sites returned to normal and minimal operational interruptions are expected heading into the fourth quarter of 2024.

The annualized impact of $0.06 per lb on Copper C1 cash costs1 from the supplementary sourcing strategy is aligned with estimates communicated in the second quarter of 2024 and expected to remain unchanged for the balance of the financial year.

_______________________

1 Copper C1 cash cost (copper C1) is a non-GAAP ratio, which does not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

ZAMBIA 2025 NATIONAL BUDGET

The 2025 National Budget was presented on September 27, 2024 by the Minister of Finance and National Planning, Dr. Situmbeko Musokotwane, under the theme "Building Resilience for Inclusive Growth and Improved Livelihoods".

No significant changes were announced to the mining tax regime, with the Minister reaffirming his commitment to maintaining stable and predictable tax policies to encourage investment.

COBRE PANAMÁ UPDATE

At the request of the Ministry of Commerce and Industries (“MICI”), Cobre Panamá delivered a draft plan for the first phase of the P&SM plan on January 16, 2024. The incoming administration reviewed the P&SM plan upon taking office in July 2024 and requested additional information, which was submitted by the Company on August 27, 2024, along with a formal presentation to MICI on September 25, 2024. The plan is still pending government approval and, therefore, not all aspects of the plan have been implemented by the Company.

During the quarter, President Mulino made public statements to the effect that his government intends to address the Cobre Panamá mine in early 2025. The Government of Panama ("GOP") also announced that an integrated audit of Cobre Panamá would be conducted with international experts to establish a factual basis to aid in decision making for the future of the mine. The Company welcomes this audit process, although the timeline remains unclear.

In parallel with the P&SM of the site, the Company has also embarked on a comprehensive program of public outreach in order to make more transparent information available to the public about Cobre Panamá. Since the beginning of 2024, these efforts have reached over 20,000 Panamanian citizens through site visits (which are currently suspended, pending P&SM approval) and briefings in universities, schools, and public spaces. A further 40,000 Panamanians have undertaken an online virtual tour of the mine.

Steps towards two arbitration proceedings have been taken by the Company, one under the Canada-Panama Free Trade Agreement (“FTA”) and the other under the International Chamber of Commerce (“ICC”) pursuant to the arbitration clause of the Refreshed Concession Contract.

- ICC Arbitration: On November 29, 2023, Minera Panamá S.A. ("MPSA") initiated arbitration before the ICC's International Court of Arbitration pursuant to the ICC’s Rules of Arbitration and Clause 46 of the Refreshed Concession Contract to protect its rights under Panamanian law and the Refreshed Concession Contract that the GOP agreed to in October 2023. The arbitration clause of the contract provides for arbitration in Miami, Florida. A final hearing for this matter is scheduled for September 2025.

- FTA Arbitration: On November 14, 2023, First Quantum submitted a notice of intent to the GOP initiating the consultation period required under the FTA. First Quantum submitted an updated notice of intent on February 7, 2024. First Quantum is entitled to seek any and all relief appropriate in arbitration, including, but not limited to, damages and reparation for Panama’s breaches of the Canada-Panama FTA. These breaches include, among other things, the GOP’s failure to permit MPSA to lawfully operate the Cobre Panamá mine prior to the Supreme Court’s November 2023 decision and the GOP’s pronouncements and actions concerning closure plans and P&SM at Cobre Panamá. The Company has the right to file its arbitration claim under the FTA within three years of Panama’s breaches of the FTA.

The Company reiterates that arbitration is not the preferred outcome for the situation in Panama and it remains committed to dialogue with the GOP and to being part of a solution for the country and its people.

KANSANSHI S3 EXPANSION

During the third quarter of 2024, assembly of the SAG and ball mills at the S3 Expansion at Kansanshi was completed and installation of the gearless mill drives commenced. Work in priority areas, including the primary crusher, continued as per schedule and focus now shifts to piping and electrical work. Commissioning activities have started in the 33kv distribution substation and is expected to be energized in the fourth quarter. System configuration of the plant control system has been completed for the primary circuit and is now focused on ancillary systems and services. The plant simulator has been made available for operator training on site. The majority of the capital spend on the S3 Expansion is expected to occur in 2024, with first production expected in the second half of 2025.

BOARD RENEWAL

As part of the ongoing board renewal program, the Company is pleased to announce the appointments of Ms. Juanita Montalvo, a Managing Partner at Acasta Cuba Capital, and Mr. Hanjun ("Kevin") Xia, currently at Jiangxi Copper, to its Board of Directors with immediate effect.

Ms. Montalvo has over 25 years of governance, executive, operations and investment experience in the mining, extractive and agricultural industries in various jurisdictions including Latin America and Africa. She is a Managing Partner at Privus Capital Inc., focused on private equity and strategic corporate investments, and an Independent Director of Dundee Precious Metals. Ms. Montalvo has held various leadership roles, including Senior Vice President Corporate Affairs and Sustainability at Sherritt International Corporation and Country Manager in Madagascar during the construction of the Ambatovy Joint Venture. She is the Chairman of Wildlife Conservation Society Canada and a founding member of the Women for Nature initiative of Nature Canada. She holds a B.Sc. in Biology and Biochemistry, a B.A. in International Development Studies, and a Masters in Development Economics, all from Dalhousie University. She is also part of McKinsey's LGBTQ Leadership Master Class Alumni and has the ICD.D designation from the Institute of Corporate Directors and Rotman School of Management.

Mr. Xia has over 20 years of experience in the global copper industry, covering the entire industrial chain from mining, smelting and processing to marketing and trading. Mr. Xia is currently at Jiangxi Copper Company Limited, holding various roles since 2001, including Coordinator in the Department of Overseas Economic and Technical Cooperation, International Cooperation Project Manager, Investor and Government Relations Manager, Director of the Office for Chairman and CEO and, more recently, President of Marketing and Trading. Mr. Xia holds a College degree in English from Shangrao Normal University and an MBA from Jiangxi University of Finance and Economics.

COMPLETE FINANCIAL STATEMENTS AND MANAGEMENT’S DISCUSSION AND ANALYSIS

The complete Consolidated Financial Statements and Management’s Discussion and Analysis for the three and nine months ended September 30, 2024 are available at www.first-quantum.com and at www.sedarplus.com and should be read in conjunction with this news release.

CONFERENCE CALL DETAILS

The Company will host a conference call and webcast to discuss the results on Wednesday, October 23, 2024 at 9:00 am (EST).

Conference call and webcast details:

Toll-free North America: 1-844-763-8274

Toll-free International: +1-647-484-8814

Webcast: Direct link or on our website

A replay of the webcast will be available on the First Quantum website.

For further information, visit our website at www.first-quantum.com or contact:

Bonita To, Director, Investor Relations

(416) 361-6400 Toll-free: 1 (888) 688-6577

E-Mail: info@fqml.com

REGULATORY DISCLOSURES

Non-GAAP and Other Financial Measures

EBITDA, ADJUSTED EARNINGS (LOSS) AND ADJUSTED EARNINGS (LOSS) PER SHARE

EBITDA, adjusted earnings (loss) and adjusted earnings (loss) per share exclude certain impacts which the Company believes are not reflective of the Company’s underlying performance for the reporting period. These include impairment and related charges, foreign exchange revaluation gains and losses, gains and losses on disposal of assets and liabilities, one-time costs related to acquisitions, dispositions, restructuring and other transactions, revisions in estimates of restoration provisions at closed sites, debt extinguishment and modification gains and losses, the tax effect on unrealized movements in the fair value of derivatives designated as hedged instruments, and adjustments for expected phasing of Zambian VAT.

| QUARTERLY | ||||||

| Q3 2024 | Q2 2024 | Q3 2023 | ||||

| Operating profit | 329 | 117 | 585 | |||

| Depreciation | 159 | 148 | 323 | |||

| Other adjustments: | ||||||

| Foreign exchange loss | 23 | 6 | 23 | |||

| Impairment expense1 | 2 | 61 | – | |||

| Restructuring expense2 | 2 | 6 | 31 | |||

| Other expense | 5 | (2 | ) | 8 | ||

| Revisions in estimates of restoration provisions at closed sites | – | – | (1 | ) | ||

| Total adjustments excluding depreciation | 32 | 71 | 61 | |||

| EBITDA | 520 | 336 | 969 | |||

1 The three and nine months ended September 30, 2024 include an impairment charge of $2 million and $71 million respectively, following the decision to scale back operations at Ravensthorpe in Q1 and subsequently placing the mine on care and maintenance in May.

2 The three months ended September 30, 2023, following a corporate reorganization within the Kansanshi segment, included a restructuring expense of $31 million.

| QUARTERLY | |||||||||

| Q3 2024 | Q2 2024 | Q3 2023 | |||||||

| Net earnings (loss) attributable to shareholders of the Company | 108 | (46 | ) | 325 | |||||

| Adjustments attributable to shareholders of the Company: | |||||||||

| Adjustment for expected phasing of Zambian VAT | (17 | ) | (27 | ) | (15 | ) | |||

| Loss on redemption of debt | – | – | – | ||||||

| Total adjustments to EBITDA excluding depreciation | 32 | 71 | 61 | ||||||

| Tax adjustments | – | 6 | (12 | ) | |||||

| Minority interest adjustments | (4 | ) | (17 | ) | – | ||||

| Adjusted earnings (loss) | 119 | (13 | ) | 359 | |||||

| Basic earnings (loss) per share as reported | $0.13 | ($0.06 | ) | $0.47 | |||||

| Diluted earnings (loss) per share | $0.13 | ($0.06 | ) | $0.47 | |||||

| Adjusted earnings (loss) per share | $0.14 | ($0.02 | ) | $0.52 | |||||

REALIZED METAL PRICES

Realized metal prices are used by the Company to enable management to better evaluate sales revenues in each reporting period. Realized metal prices are calculated as gross metal sales revenues divided by the volume of metal sold in lbs. Net realized metal price is inclusive of the treatment and refining charges (TC/RC) and freight charges per lb.

OPERATING CASHFLOW PER SHARE

In calculating the operating cash flow per share, the operating cash flow calculated for IFRS purposes is divided by the basic weighted average common shares outstanding for the respective period.

NET DEBT

Net debt is comprised of bank overdrafts and total debt less unrestricted cash and cash equivalents.

CASH COST, ALL-IN SUSTAINING COST, TOTAL COST

The consolidated cash cost (C1), all-in sustaining cost (AISC) and total cost (C3) presented by the Company are measures that are prepared on a basis consistent with the industry standard definitions by the World Gold Council and Brook Hunt cost guidelines but are not measures recognized under IFRS. In calculating the C1 cash cost, AISC and C3, total cost for each segment, the costs are measured on the same basis as the segmented financial information that is contained in the financial statements.

C1 cash cost includes all mining and processing costs less any profits from by-products such as gold, silver, zinc, pyrite, cobalt, sulphuric acid, or iron magnetite and is used by management to evaluate operating performance. TC/RC and freight deductions on metal sales, which are typically recognized as a component of sales revenues, are added to C1 cash cost to arrive at an approximate cost of finished metal.

AISC is defined as cash cost (C1) plus general and administrative expenses, sustaining capital expenditure, deferred stripping, royalties and lease payments and is used by management to evaluate performance inclusive of sustaining expenditure required to maintain current production levels.

C3 total cost is defined as AISC less sustaining capital expenditure, deferred stripping and general and administrative expenses net of insurance, plus depreciation and exploration. This metric is used by management to evaluate the operating performance inclusive of costs not classified as sustaining in nature such as exploration and depreciation.

| For the three months ended September 30, 2024 | Cobre Panamá | Kansanshi | Sentinel | Guelb Moghrein | Las Cruces | Çayeli | Pyhäsalmi | Copper | Ravensthorpe | Enterprise | Nickel | Corporate & other | Total | ||||||||||||

| Cost of sales1 | (11 | ) | (392 | ) | (309 | ) | (50 | ) | 1 | (19 | ) | (3 | ) | (783 | ) | – | (30 | ) | (30 | ) | (10 | ) | (823 | ) | |

| Adjustments: | – | ||||||||||||||||||||||||

| Depreciation | 11 | 68 | 70 | 4 | – | 1 | (1 | ) | 153 | – | 5 | 5 | 1 | 159 | |||||||||||

| By-product credits | – | 81 | – | 36 | – | 4 | 5 | 126 | – | 1 | 1 | – | 127 | ||||||||||||

| Royalties | – | 50 | 32 | 2 | – | 2 | – | 86 | – | 5 | 5 | – | 91 | ||||||||||||

| Treatment and refining charges | 1 | (5 | ) | (9 | ) | (3 | ) | – | (4 | ) | – | (20 | ) | – | – | – | – | (20 | ) | ||||||

| Freight costs | – | – | (2 | ) | – | – | (1 | ) | – | (3 | ) | – | – | – | – | (3 | ) | ||||||||

| Finished goods | – | (3 | ) | (10 | ) | 1 | – | 3 | (2 | ) | (11 | ) | – | (5 | ) | (5 | ) | – | (16 | ) | |||||

| Other4 | (2 | ) | 63 | – | 1 | – | (1 | ) | – | 61 | – | (2 | ) | (2 | ) | 9 | 68 | ||||||||

| Cash cost (C1)2,4 | (1 | ) | (138 | ) | (228 | ) | (9 | ) | 1 | (15 | ) | (1 | ) | (391 | ) | – | (26 | ) | (26 | ) | – | (417 | ) | ||

| Adjustments: | – | ||||||||||||||||||||||||

| Depreciation (excluding depreciation in finished goods) | (11 | ) | (67 | ) | (76 | ) | (5 | ) | (1 | ) | 1 | 1 | (158 | ) | – | (7 | ) | (7 | ) | (1 | ) | (166 | ) | ||

| Royalties | – | (50 | ) | (32 | ) | (2 | ) | – | (2 | ) | – | (86 | ) | – | (5 | ) | (5 | ) | – | (91 | ) | ||||

| Other | – | (3 | ) | (2 | ) | (1 | ) | (1 | ) | 1 | – | (6 | ) | – | – | – | – | (6 | ) | ||||||

| Total cost (C3)2,4 | (12 | ) | (258 | ) | (338 | ) | (17 | ) | (1 | ) | (15 | ) | – | (641 | ) | – | (38 | ) | (38 | ) | (1 | ) | (680 | ) | |

| Cash cost (C1)2,4 | (1 | ) | (138 | ) | (228 | ) | (9 | ) | 1 | (15 | ) | (1 | ) | (391 | ) | – | (26 | ) | (26 | ) | – | (417 | ) | ||

| Adjustments: | – | – | |||||||||||||||||||||||

| General and administrative expenses | (18 | ) | (7 | ) | (12 | ) | (1 | ) | – | – | – | (38 | ) | – | (1 | ) | (1 | ) | – | (39 | ) | ||||

| Sustaining capital expenditure and deferred stripping3 | – | (35 | ) | (47 | ) | (2 | ) | – | (2 | ) | – | (86 | ) | – | (15 | ) | (15 | ) | – | (101 | ) | ||||

| Royalties | – | (50 | ) | (32 | ) | (2 | ) | – | (2 | ) | – | (86 | ) | – | (5 | ) | (5 | ) | – | (91 | ) | ||||

| Lease payments | – | – | – | – | – | – | – | – | – | – | – | – | – | ||||||||||||

| AISC2,4 | (19 | ) | (230 | ) | (319 | ) | (14 | ) | 1 | (19 | ) | (1 | ) | (601 | ) | – | (47 | ) | (47 | ) | – | (648 | ) | ||

| AISC (per lb)2,4 | – | $2.15 | $2.61 | $1.55 | – | $2.54 | – | $2.42 | – | $5.97 | $5.97 | – | |||||||||||||

| Cash cost – (C1) (per lb)2,4 | – | $1.29 | $1.86 | $1.09 | – | $1.93 | – | $1.57 | – | $3.37 | $3.37 | – | |||||||||||||

| Total cost – (C3) (per lb)2,4 | – | $2.42 | $2.76 | $1.87 | – | $2.32 | – | $2.59 | – | $4.76 | $4.76 | – | |||||||||||||

1 Total cost of sales per the Consolidated Statement of Earnings (Loss) in the Company’s unaudited condensed interim consolidated financial statements.

2 C1 cash cost (C1), total costs (C3), and all-in sustaining costs (AISC) are non-GAAP ratios which do not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

3 Sustaining capital expenditure and deferred stripping are non-GAAP financial measures which do not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

4 Excludes purchases of copper concentrate from third parties treated through the Kansanshi Smelter.

| For the three months ended September 30, 2023 | Cobre Panamá | Kansanshi | Sentinel | Guelb Moghrein | Las Cruces | Çayeli | Pyhäsalmi | Copper | Corporate & other | Ravensthorpe | Total | |||||||||||

| Cost of sales1 | (497 | ) | (362 | ) | (308 | ) | (50 | ) | (15 | ) | (9 | ) | (4 | ) | (1,245 | ) | (8 | ) | (114 | ) | (1,369 | ) |

| Adjustments: | ||||||||||||||||||||||

| Depreciation | 169 | 58 | 73 | 4 | – | 4 | – | 308 | 1 | 14 | 323 | |||||||||||

| By-product credits | 72 | 43 | – | 27 | – | 1 | 5 | 148 | – | 4 | 152 | |||||||||||

| Royalties | 19 | 34 | 32 | 2 | – | – | – | 87 | – | 5 | 92 | |||||||||||

| Treatment and refining charges | (57 | ) | (7 | ) | (12 | ) | (2 | ) | – | (1 | ) | – | (79 | ) | – | – | (79 | ) | ||||

| Freight costs | – | – | (6 | ) | – | – | (1 | ) | – | (7 | ) | – | – | (7 | ) | |||||||

| Finished goods | 4 | 11 | (2 | ) | 4 | 2 | (6 | ) | (1 | ) | 12 | – | 6 | 20 | ||||||||

| Other4 | 4 | 85 | 2 | – | 13 | – | – | 104 | 7 | – | 111 | |||||||||||

| Cash cost (C1)2,4 | (286 | ) | (138 | ) | (221 | ) | (15 | ) | – | (12 | ) | – | (672 | ) | – | (85 | ) | (757 | ) | |||

| Adjustments: | ||||||||||||||||||||||

| Depreciation (excluding depreciation in finished goods) | (169 | ) | (60 | ) | (73 | ) | (5 | ) | – | (4 | ) | (1 | ) | (312 | ) | (1 | ) | (14 | ) | (327 | ) | |

| Royalties | (19 | ) | (34 | ) | (32 | ) | (2 | ) | – | – | – | (87 | ) | – | (5 | ) | (92 | ) | ||||

| Other | (5 | ) | (3 | ) | (2 | ) | – | – | – | – | (10 | ) | – | (3 | ) | (13 | ) | |||||

| Total cost (C3)2,4 | (479 | ) | (235 | ) | (328 | ) | (22 | ) | – | (16 | ) | (1 | ) | (1,081 | ) | (1 | ) | (107 | ) | (1,189 | ) | |

| Cash cost (C1)2,4 | (286 | ) | (138 | ) | (221 | ) | (15 | ) | – | (12 | ) | – | (672 | ) | – | (85 | ) | (757 | ) | |||

| Adjustments: | ||||||||||||||||||||||

| General and administrative expenses | (13 | ) | (8 | ) | (11 | ) | (1 | ) | (1 | ) | – | – | (34 | ) | – | (5 | ) | (39 | ) | |||

| Sustaining capital expenditure and deferred stripping3 | (47 | ) | (64 | ) | (46 | ) | (2 | ) | – | (2 | ) | – | (161 | ) | – | (8 | ) | (169 | ) | |||

| Royalties | (19 | ) | (34 | ) | (32 | ) | (2 | ) | – | – | – | (87 | ) | – | (5 | ) | (92 | ) | ||||

| Lease payments | – | – | – | – | – | – | – | – | – | – | – | |||||||||||

| AISC2,4 | (365 | ) | (244 | ) | (310 | ) | (20 | ) | (1 | ) | (14 | ) | – | (954 | ) | – | (103 | ) | (1,057 | ) | ||

| AISC (per lb)2,4 | $1.52 | $2.84 | $2.32 | $3.77 | – | $2.59 | – | $2.02 | – | $11.46 | ||||||||||||

| Cash cost – (C1) (per lb)2,4 | $1.19 | $1.63 | $1.65 | $3.18 | – | $1.80 | – | $1.42 | – | $9.48 | ||||||||||||

| Total cost – (C3) (per lb)2,4 | $1.99 | $2.73 | $2.46 | $4.13 | – | $2.88 | – | $2.29 | – | $11.73 | ||||||||||||

1 Total cost of sales per the Consolidated Statement of Earnings (Loss) in the Company’s unaudited condensed interim consolidated financial statements.

2 C1 cash cost (C1), total costs (C3) and all-in sustaining costs (AISC) are non-GAAP ratios which do not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

3 Sustaining capital expenditure and deferred stripping are non-GAAP financial measures which do not have a standardized meaning prescribed by IFRS and might not be comparable to similar financial measures disclosed by other issuers. See “Regulatory Disclosures”.

4 Excludes purchases of copper concentrate from third parties treated through the Kansanshi Smelter.

CAUTIONARY STATEMENT ON FORWARD-LOOKING INFORMATION

Certain statements and information herein, including all statements that are not historical facts, contain forward-looking statements and forward-looking information within the meaning of applicable securities laws. The forward-looking statements include estimates, forecasts and statements as to the Company’s expectations regarding production, sales volumes and full year copper C1 cash costs and AISC; the effect and duration of the SRA; the status of Cobre Panamá and the P&SM program and the closure of Cobre Panamá, including the timing and operating expenses thereof and the time, results of the pending environmental audit at Cobre Panamá and the process proposed by the new government in Panama; development and operation of the Company’s projects; the battery-powered dump truck trial at Kansanshi; efforts to support food security in Zambia; the effect, timing, capital expenditures and production of the S3 Expansion and the expected timeline for commissioning of the 33kV distribution substation of the S3 Expansion; the increase in throughput capacity of the Kansanshi smelter; the Company’s expectations regarding throughput capacity, mining performance and fragmentation at Sentinel; anticipated mining volumes and throughput at Enterprise; construction and commissioning of the CIL plant at Guelb Moghrein; care and maintenance costs at Ravensthorpe and the status of environmental approvals for Shoemaker Levy, Wind Farm and Tamarine Quarry; the timing of receipt of concessions, approvals, permits required for Taca Taca, including the ESIA and water use permits, and the ongoing engineering study; the amount and timing of the Company’s expenditures at La Granja, project development and the Company’s plans for community engagement and completion of an engineering study for La Granja; the curtailment of power supply in Zambia and the Company’s ability to secure sufficient power to substitute curtailments and avoid interruptions to operations; the expected positive impact of Zambia’s rainy season on improved hydropower generation; ; the Company’s future potential offtake arrangements with independent power producers; the expected impact of the 2025 Budget on increased costs for diesel and fuel heavy oil for the mining sector the timing of approval of the renewal application at Haquira and the Company’s goals regarding its drilling program; the estimates regarding the interest expense on the Company’s debt, cash flow on interest paid, capitalized interest and depreciation expense; the expected effective tax rate for the Company for 2024; the effect of foreign exchange on the Company’s cost of sales and cash costs; the Company’s hedging programs; the effect of seasonality on the Company’s results; capital expenditure and mine production costs; the outcome of mine permitting and other required permitting; the timing and outcome of legal and arbitration proceedings which involve the Company; estimates of the future price of certain precious and base metals; estimated mineral reserves and mineral resources; mineral grade estimates; the Company’s project pipeline, development and growth plans and exploration and development program, future expenses and exploration and development capital requirements; plans, targets and commitments regarding climate change-related physical and transition risks and opportunities (including intended actions to address such risks and opportunities); and greenhouse gas emissions and energy efficiency. Often, but not always, forward-looking statements or information can be identified by the use of words such as “aims”, “plans”, “expects” or “does not expect”, “is expected”, “budget”, “scheduled”, “estimates”, “forecasts”, “intends”, “anticipates” or “does not anticipate” or “believes” or variations of such words and phrases or statements that certain actions, events or results “may”, “could”, “would”, “might” or “will” be taken, occur or be achieved.

With respect to forward-looking statements and information contained herein, the Company has made numerous assumptions including among other things, assumptions about the geopolitical, economic, permitting and legal climate in which the Company operates; continuing production at all operating facilities; the price of certain precious and base metals including copper, gold, nickel, silver, cobalt, pyrite and zinc; exchange rates; anticipated costs and expenditure; the Company’s ability to secure sufficient power to avoid interruption resulting from power curtailment at its Zambian operations; mineral reserve and mineral resource estimates; the timing and sufficiency of deliveries required for the Company’s development and expansion plans; the success of Company’s actions and plans to reduce greenhouse gas emissions; and the ability to achieve the Company’s goals. Forward-looking statements and information by their nature are based on assumptions and involve known and unknown risks, uncertainties and other factors which may cause the actual results, performance or achievements, or industry results, to be materially different from any future results, performance or achievements expressed or implied by such forward-looking statements or information. These factors include, but are not limited to, future production volumes and costs, the temporary or permanent closure of uneconomic operations, costs for inputs such as oil, power and sulphur, political stability in Panama, Zambia, Peru, Mauritania, Finland, Turkey, Argentina and Australia, adverse weather conditions in Panama, Zambia, Finland, Turkey, Mauritania, and Australia, potential social and environmental challenges (including the impact of climate change), power supply, mechanical failures, water supply, procurement and delivery of parts and supplies to the operations and events generally impacting global economic, political and social stability and legislative and regulatory reform. For mineral resource and mineral reserve figures appearing or referred to herein, varying cut-off grades have been used depending on the mine, method of extraction and type of ore contained in the orebody.

See the Company’s Annual Information Form for additional information on risks, uncertainties and other factors relating to the forward-looking statements and information. Although the Company has attempted to identify factors that would cause actual actions, events or results to differ materially from those disclosed in the forward-looking statements or information, there may be other factors that cause actual results, performances, achievements or events not as anticipated, estimated or intended. Also, many of these factors are beyond First Quantum’s control. Accordingly, readers should not place undue reliance on forward-looking statements or information. The Company undertakes no obligation to reissue or update forward-looking statements or information as a result of new information or events after the date hereof except as may be required by law. All forward-looking statements made and information contained herein are qualified by this cautionary statement.

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/34b48212-3d12-4b56-80af-a3ad4794a674