Granite Creek Copper Receives Final Metallurgical Results Demonstrating 88% Oxide Copper Recovery

VANCOUVER, BC / ACCESSWIRE / January 17, 2024 / Granite Creek Copper Ltd. (TSXV:GCX)(OTCQB:GCXXF) ("Granite Creek" or the "Company") is pleased to announce significantly increased recovery of copper from oxide material at its Carmacks Copper-Gold-Silver project ("Carmacks Project" or the "Project") was achieved through metallurgical studies conducted by Kemetco Research Inc. from ("Kemetco").

The Company's 2023 Preliminary Economic Assessment ("2023 PEA") for the Project identified the opportunity to significantly increase net present value ("NPV") by improving oxide recovery. Metallurgical testing completed on the project in support of the 2023 PEA showed that while a copper recovery of over 93% could be achieved via a well-established froth flotation technique for sulphide ore, only 39.8% copper recovery from oxide ore was achieved using the same process (see Table 1 for summary of flotation results). The current test results show a total recovery of 88% for oxide material is possible, an increase of 48% over the PEA base case (Tables 1 and 2). These results will have a significant impact on the economics for the project as the PEA identified an additional $180 M of NPV5% value by increasing life of mine average recovery for copper from 64% to 77%. With sulfide recoveries of 93.7% identified in the PEA and combined oxide recoveries (initial flotation + leaching and precipitate) of 88% the potential recoveries for copper are well above the 77% target level highlighted in the 2023 PEA.

The current mine plan as outlined in the 2023 PEA contemplates processing material with a high oxide content of up to 80% oxide ore in the first five years of the mine life. During this time over 8.4 million tonnes of oxide material would be processed versus 2.88 million tonnes of sulphide material. An increase in recovery of oxide material for the first five years of mine life, as demonstrated in these test results, would have a potentially very significant impact on project economics.

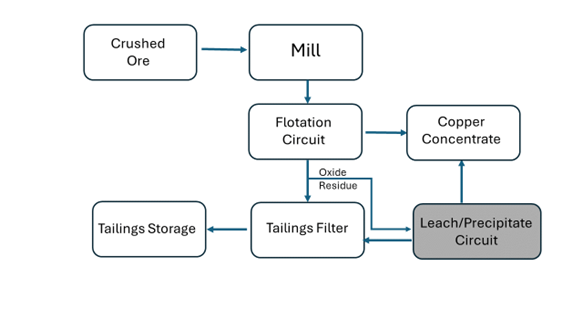

Kemetco Research Inc. was retained to complete testing on tailings produced in previous metallurgical work to develop a process for treating material that will have passed through the mill and still have significant oxide copper minerals present (See Figure 1 for simplified flow sheet). This laboratory test program showcased the efficacy of copper recovery from Carmacks copper oxide flotation tailings through a low-concentration acid leach at ambient temperature and pressure followed by chemical precipitation of copper minerals. The precipitation of copper sulphide ("CuS") from the resulting leachate was shown to be an effective method of fully recovering the leached copper from solution, yielding a very high-grade CuS precipitate that would be added to the copper concentrate further increasing the copper grade of the high-quality concentrates from the project. For reference the PEA estimated an average concentrate grade of 40% copper with significant gold and silver credits.

Figure 1: Simplified Flow Sheet

Results of this testing are outlined below:

- Acid leaching was able to extract as much as 80% of the remnant copper present in a composite prepared from Carmacks copper oxide flotation tailings.

- Copper in precipitates varied, but in most tests approached the theoretical grade of pure CuS which grades 66.5% Cu. High grades were obtained without pH adjustment.

- This testing shows a total copper recovery from oxide material of 88% with Initial Flotation recovery of 39.8% + Leach and Precipitate recovery of 48% (80% of the remnant copper).

- Adding Sodium hydrosulphide ("NaHS") solution resulted in up to 100% precipitation of copper from leach solutions, offering a promising avenue for further refinement. Hydrogen sulphide gas was equally effective as a sulphide source for copper precipitation.

- In all tests, the precipitation of CuS resulted in a drop in pH as free acid was regenerated as a by-product of the precipitation reaction, creating the potential to reuse/recycle the regenerated acid.

Table 1 Summary of flotation testing results and average values used in PEA.

Recovery % | |||

| Sample | Cu | Au | Ag |

| Sulphide Sample Flotation1 | 93.7 | 69.0 | 78.4 |

| Oxide Sample Flotation2 | 39.8 | 57.5 | 37.4 |

| Total Oxide Recovery (Initial Flotation + Leach and Precipitate) | 88.0 | N/A | N/A |

| PEA LOM Base Case3 | 64.0 | 58 | 60 |

| PEA Target Case4 | > 77 | 58 | 60 |

- Sulphide flotation testing completed by SGS prior to PEA study see news release dated January 10, 2023.

- Oxide flotation testing completed by SGS prior to PEA study see news release dated January 10, 2023.

- Calculated LOM average recovery based on a regression curve dependant on oxide content.

- Projected PEA target based on achieving a 20% increase in oxide recovery LOM.

Table 2 2023 - PEA Copper Recovery Sensitivity Table

| Copper Recovery Sensitivity | PEA BASE | Target1 | ||||

| Pre-Tax NPV (5-10% Discount) | Overall recovery | 51% | 58% | 64% | 70% | 77% |

| Sensitivity Range | 80% | 90% | 100% | 110% | 120% | |

5% | $136.6M | $231.3M | $324.1M | $416.6M | $509.6M | |

6% | $122.2M | $209.4M | $269.6M | $383.8M | $471.0M | |

7% | $107.3M | $189.4M | $271.5M | $353.6M | $453.6M | |

8% | $93.8M | $171.1M | $248.4M | $325.8M | $403.1M | |

9% | $81.4M | $154.3M | $227.3M | $300.2M | $373.2M | |

10% | $70.1M | $139.0M | $207.8M | $276.7M | $345.6M |

- Based on a recovery of 93.7% for sulphide and 88% for oxide this would exceed the PEA LOM 77% target

About the Carmacks Deposit:

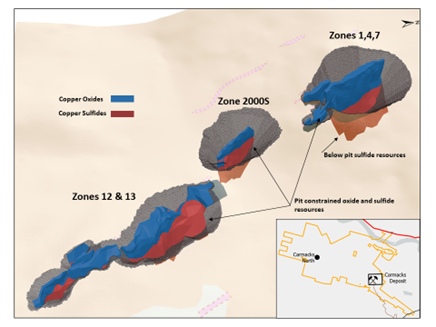

The road accessible Carmacks deposits hosts a NI 43-101 resource consisting of 36.2 Mt M&I, grading 1.07% CuEq 0.81% Cu, 0.31 g/t Au, 3.41 g/t Ag (see news release January 19, 2023). The deposit was the subject of a positive PEA released in January 2023 that envision a 9-year mine life based on a mill capable of processing 7,000 t/d of combined oxide and sulfide ore. The resources are contained within three conceptual open pits and are open for expansion.

Contained Copper in Measured and Indicated Resources

147 Pit 280 Mlbs copper in oxide

126 Mlbs copper in sulfide

2000 Pit 10.5 Mlbs copper in oxide

51.3 Mlbs copper in sulfide

1213 Pit 35.4 Mlbs copper in oxide

122.3 Mlbs copper in sulfide

Tim Johnson, President & CEO stated, "The 2023 PEA, a major milestone for the Company, identified several opportunities for the Project including increased recovery, resource expansion and additional mine and process optimisation. The unlocking of additional value through the improved oxide recovery that this testing represents, especially in the early years of mine life, has the potential to add significantly to the NPV of the project. These results could allow for re-evaluation of resources that didn't make it into the mine plan due to lower grades or assumed recoveries. The process being developed by the company also has the possibility of being used in other parts of the Minto Copper belt where oxidized or partially oxidized (POX) copper ores have not been processed by other operators."

Corporate Update

Granite Creek announces the appointment of Susan Henderson as Corporate Secretary. In this role, Ms. Henderson will play a crucial role in overseeing and managing corporate governance matters, ensuring compliance with regulatory requirements, and serving as a key liaison between the company and its stakeholders. She brings her extensive experience in the mining industry, making her well-suited to contribute to Granite Creek's continued success. The board and executive team are confident in her ability to navigate the complex landscape of corporate governance and provide valuable insights.

Qualified Persons

Mr. Douglas Warkentin, P.Eng., a Qualified Person for the purposes of National Instrument 43-101, has reviewed and approved the technical disclosure related to metallurgical testing contained in this news release. Mr. Warkentin is a Senior Metallurgist with Kemetco Research and an advisor to the Company.

The NI 43-101 technical report entitled CARMACKS PROJECT PRELIMINARY ECONOMIC ASSESMENT (PEA) YUKON, CANADA, referenced in this news release is available on the company's website as well as on SEDAR under the company's profile.

2023 PEA: The Company cautions that the results of the PEA are preliminary in nature and do not include the calculation of mineral reserves as defined by NI 43-101. There is no certainty that the results of the PEA will be realized.

About Granite Creek Copper

Granite Creek Copper, a member of the Metallic Group of Companies, is a focused on the exploration and development of critical minerals projects in North America. The Company's projects consist of its flagship 176 square kilometer Carmacks project in the Minto copper district of Canada's Yukon Territory on trend with the high-grade Minto copper-gold mine and the advanced stage LS molybdenum project and the Star copper-nickel-PGM project, both located in central British Columbia. More information about Granite Creek Copper can be viewed on the Company's website at www.gcxcopper.com.

FOR FURTHER INFORMATION PLEASE CONTACT:

Timothy Johnson, President & CEO

Telephone: 1 (604) 235-1982

Toll Free: 1 (888) 361-3494

E-mail: info@gcxcopper.com

Website: www.gcxcopper.com

Metallic Group: www.metallicgroup.ca

Forward-Looking Statements

Forward Looking Statements: This news release includes certain statements that may be deemed "forward-looking statements". All statements in this release, other than statements of historical facts including, without limitation, statements regarding potential mineralization, historic production, estimation of mineral resources, the realization of mineral resource estimates, interpretation of prior exploration and potential exploration results, the timing and success of exploration activities generally, the timing and results of future resource estimates, permitting time lines, metal prices and currency exchange rates, availability of capital, government regulation of exploration operations, environmental risks, reclamation, title, and future plans and objectives of the company are forward-looking statements that involve various risks and uncertainties. Although Granite Creek Copper believes the expectations expressed in such forward-looking statements are based on reasonable assumptions, such statements are not guarantees of future performance and actual results or developments may differ materially from those in the forward-looking statements. Forward-looking statements are based on a number of material factors and assumptions. Factors that could cause actual results to differ materially from those in forward-looking statements include failure to obtain necessary approvals, unsuccessful exploration results, changes in project parameters as plans continue to be refined, results of future resource estimates, future metal prices, availability of capital and financing on acceptable terms, general economic, market or business conditions, risks associated with regulatory changes, defects in title, availability of personnel, materials and equipment on a timely basis, accidents or equipment breakdowns, uninsured risks, delays in receiving government approvals, unanticipated environmental impacts on operations and costs to remedy same, and other exploration or other risks detailed herein and from time to time in the filings made by the companies with securities regulators. Readers are cautioned that mineral resources that are not mineral reserves do not have demonstrated economic viability. Mineral exploration and development of mines is an inherently risky business. Accordingly, the actual events may differ materially from those projected in the forward-looking statements. For more information on Granite Creek Copper and the risks and challenges of their businesses, investors should review their annual filings that are available at www.sedar.com.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

SOURCE: Granite Creek Copper Ltd.

View the original press release on accesswire.com