Medallion Commissions Life Cycle Assessment to Quantify Climate Change and Environmental Impact

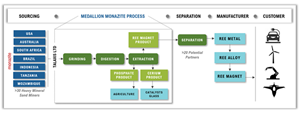

VANCOUVER, British Columbia, Jan. 05, 2021 (GLOBE NEWSWIRE) -- Medallion Resources Ltd. (TSX-V: MDL; OTCQB: MLLOF; Frankfurt: MRDN) – “Medallion” or the “Company”), is pleased to announce the engagement of Minviro Ltd, a UK-based global leader in Life Cycle Assessment (LCA), to deliver an ISO-compliant gate-to-gate LCA model for the proprietary Medallion Monazite Process which extracts rare-earth elements (REE) from mineral sand monazite. Minviro will use data generated from the ongoing techno-economic assessment (TEA) of the Medallion Monazite Process which is anticipated to be delivered during Q1 2021.

Life Cycle Assessment is a widely accepted and robust numerical method used to quantify climate change and other environmental impacts for industrial processes, while identifying opportunities for impact reduction and process improvement.

“Medallion has developed a disruptive and innovative process to deliver REEs with the minimum environmental and carbon footprint,” said Mark Saxon President & CEO. “Seeking the most efficient use of raw materials, energy and reagents is the fundamental basis of our engineering efforts and stands Medallion Monazite Process apart from peers. Our ability to utilize the best technology at optimal sites provides an attractive opportunity to maximize profitability and minimize environmental impact. We are incorporating this thinking into all of our supply chain conversations and partnerships.”

Dr Robert Pell, Founder & Director of Minviro further states, “REE production has a legacy of social and environmental impacts. As REE demand grows in line with renewable energy and EV uptake, it is important that steps are taken to measure and mitigate the environmental impact of producing these essential elements. Delivery of an LCA is a central part of this process for the battery and EV industries as it provides customers with the necessary data to measure their impact, compare process or supplier scenarios and optimize the environmental performance of projects.”

The Medallion Monazite Process does not require additional mining to produce REEs, utilizes a high-grade by-product mineral that typically goes to waste, makes use of Process Intensification design practice that maximizes energy and reagent re-use, and produces zero liquid waste output. The climate change and other environmental impact benefits of the process will be quantified by the LCA. As the Medallion Monazite Process is both scalable and transferable it can be implemented at ideal locations and scales to maximize profitability and minimize the carbon dioxide impact of long-distance feedstock and reagent transport.

Rare-earth element demand growth is linked to low-carbon emitting technologies, including wind energy and electromobility where efficiency is enabled by high-strength REE permanent magnets. Many industrial customers in these fields, such as automakers, seek to make the most sustainable purchasing decisions for REEs and battery materials, and the data-driven approach of an LCA with ISO-compliance provides them the highest degree of transparency and customer confidence.

Minviro Ltd has recently completed, or are engaged for LCA assessments, for various processes and products being developed in the battery raw materials markets. Minviro will use data generated from the techno-economic assessment of the Medallion Monazite Process. The LCA includes a gate-to-gate life cycle inventory and life cycle impact assessment for five impact categories including carbon footprint, alongside recommended impact mitigation opportunities. The results will be delivered to the Company in the form of an ISO-compliant and third-party reviewed Life Cycle Assessment (LCA) Report.

The Medallion Monazite Process was developed utilizing “best available technology” (BAT) principles and is consequently a highly optimized and automated design that is transferable in location and scalable in size as REE demand grows. The process reflects the current and future expectations of REE customers in the rapidly growing electric vehicle and wind energy markets by providing the lowest impact, most sustainable and resource efficient primary raw material sourcing available.

The Medallion Monazite Process uses by-product materials that presently pass to waste in the mineral sand industry, or to Chinese customers, and therefore additional mining is not required. It produces zero liquid waste, has a high degree of energy and chemical reuse and regeneration, and will convert greater than 95% of monazite feed to saleable REE and phosphate products.

Medallion’s REE Production Approach

Monazite is used today as a source of REEs in both China and India, where it is considered an attractive feedstock due to its high REE content (up to 65% REE by weight), and the relatively high abundance of the magnet metals neodymium (Nd) and praseodymium (Pr).

The Company has developed the Medallion Monazite Process, a proprietary method and related business model, to achieve low-cost, near-term, REE production utilizing mineral sand monazite. Monazite is a rare-earth phosphate mineral globally available as a by-product from heavy mineral sand-mining operations.

About Medallion Resources

Medallion Resources has developed a proprietary process and related business model to achieve low-cost, near-term, rare-earth element (REE) production by exploiting monazite. Monazite is a rare-earth phosphate mineral that is widely available as a by-product from mineral sand mining operations. REEs are critical inputs to electric and hybrid vehicles, electronics, imaging systems, wind turbines and strategic defense systems. Medallion is committed to following best practices and accepted international standards in all aspects of mineral transportation, processing, and the safe management of waste materials.

More about Medallion (TSX-V: MDL; OTCQB: MLLOF; Frankfurt: MRDN) can be found at medallionresources.com.

Contact(s):

Mark Saxon, President & CEO

Donald Lay, Director & Vice President, Corporate Development

+1.604.681.9558 or info@medallionresources.com

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Medallion management takes full responsibility for content and has prepared this news release. Some of the statements contained in this release are forward-looking statements, such as statements that describe Medallion’s plans with respect to the completion of additional tranche(s) of the Offering and the intended use of the proceeds. Since forward-looking statements address future events and conditions, by their very nature, they involve inherent risks and uncertainties, including the risks related to market conditions and regulatory approval and other risks outlined in the Company’s management discussions and analysis of financial results. Actual results in each case could differ materially from those currently anticipated in these statements. Also, in order to proceed with Medallion’s plans, additional funding will be necessary and, depending on market conditions, this funding may not be forthcoming on a schedule or on terms that facilitate Medallion’s plans. These forward-looking statements are made as of the date of this press release, and, other than as required by applicable securities laws, Medallion disclaims any intent or obligation to update publicly any forward-looking statements, whether as a result of new information, future events or results or otherwise.

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/c439d4e2-72e6-4361-99fd-d1675102aae5