Monument Announces Trial Mining Results at Peranggih Gold Prospect in Malaysia

VANCOUVER, British Columbia, April 20, 2020 (GLOBE NEWSWIRE) -- Monument Mining Limited (TSX-V: MMY and FSE: D7Q1) (“Monument” or the “Company”) is pleased to announce the results from the trial mining program at Peranggih Gold Prospect (“Peranggih”), 14km north of Selinsing Gold Mine in Pahang State, Malaysia.

Peranggih is a new oxide exploration target. Gold mineralization is structurally controlled and similar to Selinsing and Buffalo Reef mineralization in terms of both the regional geological and structural setting, hosted in a regional shearing and faulted zone. At Peranggih Central (trial mining site), the mineralization is regionally trending NNW-SSE at about 340-350 north azimuth.

The trial mining was carried out from February 22 to March 3, 2020, under which the bulk sample was extracted from the higher mineralized area at Peranggih (Figure 1) and fed into the Selinsing gold processing plant to confirm the average grade, quantify the presence of coarse gold, and test the metallurgical performance at plant scale.

Figure 1 accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/1794ce6b-c9db-429b-b876-145d81d187cb

Highlight of Results from Trial Mining Program

- Material mined in the stage one pit was 15,677 tonnes at an average grade of 1.22g/t, slightly lower but still in line with 17,309 tonnes from a block model at 1.19g/t, and 17,060 tonnes from the 2018 grade control at 1.36g/t.

- Out of 15,677 tonnes of material mined, 13,047 tonnes of material was processed at a reconciled head grade of 1.17g/t with actual recovery of 89.8% from reconciliation of opening and closing of gold in circuit based on gold loaded onto activated carbon, physical gold recovered by electrowinning and gold in tailings, as compared to an average assayed grade gold of 1.22g/t with recovery of 90.2% from plant sampling of mill feed and tailings. Both gravity and leach responses were very encouraging.

Bulk Sample Drilling and Mining

The bulk samples for the trial mining were selected from the exposed mineralization in the historic mining area at Central Peranggih, which combined easy access, favorable topography and a low stripping ratio, where a 5m x 5m close spaced RAB grade control drilling program was completed in November 28, 2017. The drill program successfully delineated a zone of higher grade gold material at Peranggih Central by testing an area of 150m strike length by 80m width and 20m depth, known to contain a significant amount of coarse gold in a hydrothermal breccia system.

Mining of the Peranggih bulk sample material was controlled by the revised pit design developed from the block model and the grade control drilling. Mining was conducted in 2m benches, and the bulk sample materials hauled to the Pantos Interim Stockpile 7km south of Peranggih, and then to Selinsing plant ROM pad another 7km to the south via the newly constructed access road. The bulk sample material mined was all free-digging with no drilling and blasting carried out during the trial mining. The mining results are presented below in Table 1.

| Table 1: Peranggih Trial Mining Campaign – Mined Bulk Sample Materials | ||||||

| Unit | Mined | Block Model | Grade Control | Mined vs BM | Mined vs GC | |

| Volume | m3 | 7,126 | 7,901 | 7,581 | 90% | 94% |

| Tonnes | t | 15,677 | 17,309 | 17,060 | 91% | 92% |

| Grade | g/t Au | 1.22 | 1.19 | 1.36 | 102% | 90% |

| Ounces | oz. | 612 | 664 | 745 | 92% | 82% |

A total of 15,677 tonnes of bulk sample material was mined at an average grade of 1.22 g/t Au. The tonnage of bulk samples mined was 8% lower than the grade control tonnage due to a combination of topographical and density variance. The bulk sample mined grade was 10% lower than grade control due to waste dilution in the mined bulk sample blocks and the wider spacing of the GC drill samples.

The block model was redesigned with a shallower batter slope angle of 45 degrees compared to the original block model with a slope angle of 70 degrees due to a heavy rain caused the high wall to collapse when striping work commenced. The original Peranggih trial pit design planned for a total of 8,934 tonnes at 1.87g/t Au for 537 ounces.

Plant Scale Testwork

Analytical results for the calculated gold grade were based on processing the individual composited bulk samples through Selinsing’s gold processing plant. The process plant incorporated crushing and ball milling where the cyclone overflow reported to the leach circuit, from which carbon was taken through the elution column and gold solution to the electrowinning cells; cyclone underflow reported to the Knelson Concentrator and concentrates were sent to the Acacia reactor, then to electrowinning cells for final gold recovery.

Prior to the commencement of bulk sample processing, the crushed bulk sample stockpile was levelled and surveyed; gold in circuit surveys were conducted before and after the processing campaign.

Due to the minimal amount of hard rock, the crushing plant was configured with just the jaw crusher and secondary cone crusher in operation and the product screen was decked out with 22mm panels. The bulk sample was crushed at an average rate of 126 tph. Feed rates of up to 149 tph were achieved with relatively dry feed though throughput was reduced when crushing clay-rich feed that became wet and sticky after rain causing chute blockages. Size analyses on the crushed bulk sample materials/mill feed gave an average P80 of 9.1 mm.

A total of 13,047 dry tonnes of Peranggih bulk sample was processed over seven days at an average feed rate of 80 tph. The primary and secondary ball mills were operating with both Knelson concentrators online. The Peranggih bulk sample was found to be relatively soft and the average grind size P80 was 39 microns. The mill power consumed during the Peranggih campaign indicated a work index of a relatively low 11.8 kWh/tonne.

Knelson concentrates were harvested every 45-60 minutes and accumulated over 12 hours before intensive leaching in the Acacia reactor. Caustic soda, sodium cyanide and leach accelerant was added to the Acacia strip solution and the intensive leach cycle was completed within 12 hours. Intensive leach recovery was high, with two test results given an average 99.3% recovery. The mass yield of gravity concentrate from Peranggih bulk sample was not excessive and intensive leaching reverted to a daily cycle, with Knelson concentrates accumulated over 24 hours. Pregnant Acacia solution was sent to the electrowinning cells for final gold recovery. Reconciled gravity gold recovery by the Knelson concentrators and Acacia reactor was 19.9%.

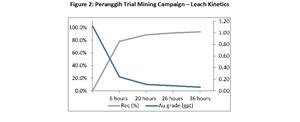

Cyclone overflow reported to the leach circuit with two leach and six CIL tanks operating for a total of 36 hours retention time. Sodium cyanide concentration was targeted at 220 ppm in the first leach tank; hydrated lime was added to control the slurry at pH 10.3, slightly lower than the usual pH 10.5 in order to control the higher than normal viscosity of the Peranggih bulk samples. Leach kinetics were excellent with sampling of the leach circuit indicating up to 78.5% gold in solution after the first leach tank, equivalent to 6 hours retention time; unit leach/CIL recovery was 83.8% and reconciled overall leach/CIL recovery was 69.9% (Figure 2. Peranggih Trial Mining Campaign – Leach Kinetics). Sodium cyanide and lime consumptions were 0.9 and 3.1 kg/tonne respectively and considered fairly normal relative to the oxide ores extracted from Selinsing and Buffalo Reef.

Figure 2 accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/abd1455e-fc0d-4eff-b00a-9f3694dcf876

Grade Reconciliation and Gold Recovery

Total gold recovery from the Peranggih bulk sample was a very encouraging 89.8% from a reconciled mill feed of 1.17 g/t Au. Check assays were carried out on samples of ball mill feed and cyclone overflow. The assayed gold in mill feed gave an average 1.22 g/t Au and cyclone overflow (gravity tailings) was 0.96 g/t Au, indicating a gravity recovery of 21.4%, slightly more than the reconciled recovery of 19.9%.

Assay leach/CIL recovery was calculated as 68.8%, comparing favorably with the reconciled recovery of 69.9%. Overall total recovery was 90.2%, compared to the reconciled recovery of 89.8%. The reconciled mill feed grade was 4.0% less than the assayed mill feed grade; for the relatively short campaign the reconciled and assay recoveries and grades were in reasonable agreement.

| Table 2: Peranggih Trial Mining Campaign – Processed Bulk Sample | ||||

| Description | tonnes | g/t Au | g Au | % |

| Dry tonnes crushed and milled | 13,047 | |||

| Gravity recovered gold | 0.23 | 3,048.0 | 19.9% | |

| Leach/CIL recovered gold | 0.82 | 10,699.9 | 69.9% | |

| Reconciled total gold recovered | 1.05 | 13,747.9 | 89.8% | |

| Gold in final tail | 0.12 | 1,562.1 | 10.2% | |

| Reconciled gold in mill feed | 1.17 | 15,310.0 | 100.0% | |

| Check assays | ||||

| Gold in gravity tailings | 0.96 | 12,517.1 | ||

| Gold in final tailings | 0.12 | 1,562.1 | ||

| Assayed gold in mill feed | 1.22 | 15,917.9 | ||

| Assay gravity recovery | 21.4% | |||

| Assay leach/CIL recovery | 68.8% | |||

| Assay total recovery | 90.2% | |||

| Mill feed grade variance | -4.0% | |||

Both gravity and leach responses were very encouraging. No serious material handling problems were encountered with the Peranggih bulk sample. Future campaigns will benefit from blending with more competent ore from the Selinsing pits to help both materials being handled in the crushing plant and slurry characteristics in the leach circuit.

A new grade control program is currently in the planning stage with 5,000 metres of drilling. In addition, a further exploration drilling program has been proposed to define the extensions of the known mineralization along strike to the Northeast and Southwest. Further mineralized materials might be fed into the mill from time to time once the results of grade control are satisfactory.

Risk Factors

There is currently no NI 43-101 mineral resource estimate established anywhere on the Peranggih Gold Prospect.

All of the bulk sample material was removed from a single location known as Pit 1 (see Figure 1). Pit 1 was selected because it was considered to have representative grade, and was ideally located for easy extraction. There is no assurance that mining or bulk sampling in another location at Peranggih would result in similar gold content or recovery.

During the sample test process through Selinsing processing plant, it is possible that preexisting gold contained in the circuit was flushed out while processing the bulk sample. Similarly, the bulk sample could have deposit gold residue in the circuit. It is unknown to what extent this may have contributed to inaccuracies in the results. There is no certification as to the precision of the results and readers should use caution in their use and interpretation.

The scientific and technical information in this press release has been prepared by Azman Taib, B.Eng. (Mineral Resource), Metallurgist of Selinsing Gold Mine; reviewed and approved by Michael John Kitney, MAICD, MSc., MAusIMM, a Qualified Person as defined by NI43-101.

About Monument

Monument Mining Limited (TSX-V: MMY, FSE: D7Q1) is an established Canadian gold producer that owns and operates the Selinsing Gold Mine in Malaysia. Its experienced management team is committed to growth and is advancing several exploration and development projects including the Mengapur Copper-Iron Project, in Pahang State of Malaysia, and the Murchison Gold Projects comprising Burnakura, Gabanintha and Tuckanarra in the Murchison area of Western Australia. The Company employs approximately 195 people in both regions and is committed to the highest standards of environmental management, social responsibility, and health and safety for its employees and neighboring communities.

Cathy Zhai, President and CEO

Monument Mining Limited

Suite 1580 -1100 Melville Street

Vancouver, BC V6E 4A6

FOR FURTHER INFORMATION visit the company web site at www.monumentmining.com or contact:

Richard Cushing, MMY Vancouver T: +1-604-638-1661 x102 rcushing@monumentmining.com

"Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release."

Forward-Looking Statement

This news release includes statements containing forward-looking information about Monument, its business and future plans (“forward-looking statements”). Forward-looking statements are statements that involve expectations, plans, objectives or future events that are not historical facts and include the Company’s plans with respect to its mineral projects and the timing and results of proposed programs and events referred to in this news release. Generally, forward-looking information can be identified by the use of forward-looking terminology such as "plans", "expects" or "does not expect", "is expected", "budget", "scheduled", "estimates", "forecasts", "intends", "anticipates" or "does not anticipate", or "believes", or variations of such words and phrases or state that certain actions, events or results "may", "could", "would", "might" or "will be taken", "occur" or "be achieved". The forward-looking statements in this news release are subject to various risks, uncertainties and other factors that could cause actual results or achievements to differ materially from those expressed or implied by the forward-looking statements. These risks and certain other factors include, without limitation: risks related to general business, economic, competitive, geopolitical and social uncertainties; uncertainties regarding the results of current exploration activities; uncertainties in the progress and timing of development activities; foreign operations risks; other risks inherent in the mining industry and other risks described in the management discussion and analysis of the Company and the technical reports on the Company’s projects, all of which are available under the profile of the Company on SEDAR at www.sedar.com. Material factors and assumptions used to develop forward-looking statements in this news release include: expectations regarding the estimated cash cost per ounce of gold production and the estimated cash flows which may be generated from the operations, general economic factors and other factors that may be beyond the control of Monument; assumptions and expectations regarding the results of exploration on the Company’s projects; assumptions regarding the future price of gold of other minerals; the timing and amount of estimated future production; the expected timing and results of development and exploration activities; costs of future activities; capital and operating expenditures; success of exploration activities; mining or processing issues; exchange rates; and all of the factors and assumptions described in the management discussion and analysis of the Company and the technical reports on the Company’s projects, all of which are available under the profile of the Company on SEDAR at www.sedar.com. Although the Company has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking statements, there may be other factors that cause results not to be as anticipated, estimated or intended. There can be no assurance that such statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Accordingly, readers should not place undue reliance on forward-looking statements. The Company does not undertake to update any forward-looking statements, except in accordance with applicable securities laws.