Noront Announces Results of Metallurgical Test Work for Eagle's Nest and Reports Test Drilling Assays

TORONTO, Dec. 02, 2020 (GLOBE NEWSWIRE) -- Noront Resources Ltd. (“Noront” or the “Company”) (TSX Venture: NOT) today updated the metallurgical information for its Eagle’s Nest Mine Project and provided results from its 2020 drilling program.

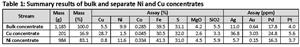

Metallurgical testing conducted by Expert Process Solutions (XPS), a GLENCORE company, demonstrated very good overall metallurgical performance of the Eagle’s Nest ore with strong indications of the production of high-quality marketable copper and nickel concentrates, low in magnesium oxide (MgO) at high metal recoveries. Locked cycle tests on a representative sample produced a bulk concentrate followed by separate nickel and copper concentrates with results shown in Table 1.

Table 1: Summary results of bulk and separate Ni and Cu concentrates

| Stream | Mass (g) | Mass (%) | Assay (%) | Assay (ppm) | |||||||||

| Cu | Ni | Co | Fe | S | MgO | SiO2 | Ag | Au | Pd | Pt | |||

| Bulk concentrate | 1,185 | 100.0 | 5.5 | 9.9 | 0.285 | 39.5 | 31.1 | 4.2 | 5.5 | 11.0 | 0.64 | 17.8 | 4.0 |

| Cu concentrate | 201 | 16.9 | 28.7 | 1.5 | 0.045 | 30.5 | 32.0 | 2.6 | 3.3 | 36.8 | 3.03 | 24.8 | 5.6 |

| Ni concentrate | 984 | 83.1 | 0.8 | 11.6 | 0.334 | 41.3 | 31.0 | 4.5 | 5.9 | 5.7 | 0.15 | 16.3 | 3.7 |

To see an image of Table 1: Summary results of bulk and separate Ni and Cu concentrates, please visit the following link: https://www.globenewswire.com/NewsRoom/AttachmentNg/2d63007a-7566-4e6c-8ac8-5fb19c1032bc

XPS modeling indicated further enhancement of the separate concentrates is possible, including reduction of nickel content in the copper concentrate. Noront plans to conduct continuous pilot plant testing work on recently drilled core samples to confirm this modeling.

“These are important results as they enable us to pursue multiple marketing options for our concentrates,” said Noront President and CEO Alan Coutts. “Not only can Noront sell high quality products to traditional Canadian and international refining companies, but we can also provide dedicated nickel concentrates to the emerging battery metals sector.”

2020 Metallurgical Drilling

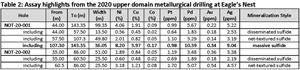

In early 2020 Noront executed a metallurgical drilling campaign to collect additional sample material from the Eagle’s Nest deposit for future variability testing. Four holes totalling 642m were drilled, including two holes into the upper domain and two wedge holes into the lower domain. The upper domain holes were continuously assayed to better inform the resource model. The lower domain holes were only sporadically assayed to preserve sufficient material for future metallurgical testing. Table 2 summarizes assay results of the upper domain holes and showcases the incredible metal tenor of the Eagle's Nest sulfide ores. A composite photo of the massive sulfide intersection in NOT-20-001 is shown in Figure 1.

Table 2: Assay highlights from the 2020 upper domain metallurgical drilling at Eagle’s Nest

| Hole | From (m) | To (m) | Width (m) | Ni (%) | Cu (%) | Co (%) | Pt (ppm) | Pd (ppm) | Au (ppm) | Ag (ppm) | Mineralization Style |

| NOT-20-001 | 44.00 | 143.35 | 99.35 | 4.06 | 1.91 | 0.09 | 0.99 | 5.67 | 0.22 | 5.22 | |

| Including | 44.00 | 57.50 | 13.50 | 0.56 | 0.45 | 0.02 | 0.64 | 1.83 | 0.18 | 2.53 | disseminated sulfide |

| Including | 57.50 | 107.3 | 49.80 | 2.01 | 0.82 | 0.05 | 1.10 | 3.29 | 0.14 | 3.19 | net-textured sulfide |

| Including | 107.30 | 143.35 | 36.05 | 8.20 | 3.97 | 0.17 | 0.98 | 10.39 | 0.34 | 9.04 | massive sulfide |

| NOT-20-002 | 35.00 | 86.00 | 51.00 | 1.89 | 0.84 | 0.05 | 1.19 | 3.48 | 0.36 | 3.38 | |

| Including | 35.00 | 60.50 | 25.50 | 0.60 | 0.48 | 0.02 | 0.69 | 1.89 | 0.18 | 2.19 | disseminated sulfide |

| Including | 60.5 | 86.00 | 25.50 | 3.18 | 1.21 | 0.08 | 1.70 | 5.07 | 0.54 | 4.57 | net-textured sulfide |

To see an image of Table 2: Assay highlights from the 2020 upper domain metallurgical drilling at Eagle’s Nest, please visit the following link: https://www.globenewswire.com/NewsRoom/AttachmentNg/b4354eb5-a277-4655-8365-a3b9cc7f12ea

Ring of Fire Nickel Prospectivity

The grade of known nickel-copper-PGE sulfides in the Ring of Fire is comparable to some of the richest nickel deposits in the world. The high tenor nature of magmatic sulfides at Eagle's Nest coupled with the proven conditions for formation of a sizeable nickel deposit presents a compelling case for continued nickel exploration in the region.

In 2019, the Company completed a nickel targeting exercise which identified over 70 early stage nickel targets in the Ring of Fire. The Victory target, staked in early 2020 was a product of this work. A recently completed VTEM-plus survey over the Victory property identified several mid-time EM conductors associated with magnetic targets of possible ultramafic source. Noront is examining follow-up ground EM surveys to better resolve these targets ahead of drilling.

In addition, a thorough, independent review of the extensive geophysical database will be commissioned to identify previously overlooked or undertested priority EM anomalies with nickel potential. It is worth noting that the Company’s geophysical database in the Ring of Fire consists of over 130 airborne EM surveys, over 250 ground EM surveys as well as numerous other surveys of different types (e.g., gravity, IP). Most of these surveys were completed by previous operators in the early days of Ring of Fire exploration prior to our current understanding of the geology in the region. A re-evaluation of this extensive dataset is timely and may yield a significant number of quality untested targets.

XPS Metallurgical Test Work Detail

Eagle’s Nest is a high-grade nickel-copper-PGE deposit, located in the emerging mining region known as the Ring of Fire in Northwestern Ontario. Noront filed an NI 43-101 compliant technical report for this project in 2012, applying mineralogical and metallurgical test work by SGS Lakefield.

The 2020 mineralogical and metallurgical work was commissioned to verify that marketable, separate nickel and copper concentrates could be prepared with representative sulfide samples from the deposit. Open-circuit tests were used to define and tune the processes to produce a bulk concentrate, consistent with previous SGS work and to split it into two concentrates via a separation process. Locked-cycle tests were run to examine the final process performance, based on a sample prepared by XPS. Since bench tests do not fully yield the results that can be attained in a full-scale plant with columns and re-circulating loads, XPS developed simulation software to estimate the expected final products to be produced at the full-scale plant.

XPS used material and composite samples that had been stored in SGS Lakefield’s freezer for the initial work. The condition of this material was verified by replicating the SGS process using the same historic blend ratios of net-textured to massive sulfide used by SGS to produce bulk concentrates with similar properties as the SGS work. XPS then used material from the composites to prepare a new representative composite blend of 83:17 (net-textured to massive sulfide) to test the revised process steps.

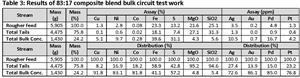

Test work with open circuits on the 83:17 blend was done to refine the flow sheet and produce an improved bulk concentrate process. XPS then moved on to locked-cycle tests with the new 83:17 composite to produce a bulk concentrate and then separate nickel and copper concentrates. The bulk concentrate circuit produced stable results and yielded recoveries of 91.8% Cu, 83.1% Ni, 81.8% Co, 72.6% Ag, 86.1% Au, 85.0% Pd and 76.8% Pt into a bulk concentrate with 5.1% Cu, 9.7% Ni and 31.1% S (Table 3). Importantly, the magnesium level of the bulk concentrate was 4.3% MgO.

Table 3: Results of 83:17 composite blend bulk circuit test work

| Stream | Mass (g) | Mass (%) | Assay (%) | Assay (ppm) | |||||||||

| Cu | Ni | Co | Fe | S | MgO | SiO2 | Ag | Au | Pd | Pt | |||

| Rougher Feed | 5,905 | 100.0 | 1.3 | 2.8 | 0.08 | 23.3 | 13.2 | 21.6 | 25.1 | 3.5 | 0.2 | 4.8 | 1.3 |

| Total Tails | 4,475 | 75.8 | 0.1 | 0.6 | 0.02 | 18.1 | 7.4 | 27.1 | 31.3 | 1.3 | 0.0 | 0.9 | 0.4 |

| Total Bulk Conc. | 1,430 | 24.2 | 5.1 | 9.7 | 0.28 | 39.6 | 31.1 | 4.3 | 5.6 | 10.5 | 0.7 | 16.7 | 4.2 |

| Stream | Mass (g) | Mass (%) | Distribution (%) | Distribution (%) | |||||||||

| Cu | Ni | Co | Fe | S | MgO | SiO2 | Ag | Au | Pd | Pt | |||

| Rougher Feed | 5,905 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| Total Tails | 4,475 | 75.8 | 8.2 | 16.9 | 18.2 | 58.9 | 42.8 | 95.2 | 94.6 | 27.4 | 13.9 | 15.0 | 23.2 |

| Total Bulk Conc. | 1,430 | 24.2 | 91.8 | 83.1 | 81.8 | 41.1 | 57.2 | 4.8 | 5.4 | 72.6 | 86.1 | 85.0 | 76.8 |

To see an image of Table 3: Results of 83:17 composite blend bulk circuit test work, please visit the following link: https://www.globenewswire.com/NewsRoom/AttachmentNg/ecae2c1c-d6d7-4db8-82bf-d8354df11d97

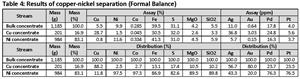

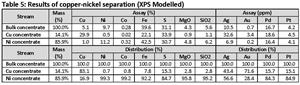

Test results of the copper-nickel separation are shown in Table 4. They indicate substantial copper-nickel separation is achievable. The observed level of nickel in the copper concentrate exceeds the assumed commercial target, however this is a common feature of most copper-nickel separation bench-scale testing. To overcome this, XPS developed a proprietary modelling program to predict metallurgical performance at the plant scale based on bench scale test work. Table 5 summarizes the modelled copper-nickel separation results for the Eagle’s Nest 83:17 composite blend and indicates nickel values below 1% in the copper concentrate, a key objective for marketable copper concentrates worldwide.

Table 4: Results of copper-nickel separation (Formal Balance)

| Stream | Mass (g) | Mass (%) | Assay (%) | Assay (ppm) | |||||||||

| Cu | Ni | Co | Fe | S | MgO | SiO2 | Ag | Au | Pd | Pt | |||

| Bulk concentrate | 1,185 | 100.0 | 5.5 | 9.9 | 0.285 | 39.5 | 31.1 | 4.2 | 5.5 | 11.0 | 0.64 | 17.8 | 4.0 |

| Cu concentrate | 201 | 16.9 | 28.7 | 1.5 | 0.045 | 30.5 | 32.0 | 2.6 | 3.3 | 36.8 | 3.03 | 24.8 | 5.6 |

| Ni concentrate | 984 | 83.1 | 0.8 | 11.6 | 0.334 | 41.3 | 31.0 | 4.5 | 5.9 | 5.7 | 0.15 | 16.3 | 3.7 |

| Stream | Mass (g) | Mass (%) | Distribution (%) | Distribution (%) | |||||||||

| Cu | Ni | Co | Fe | S | MgO | SiO2 | Ag | Au | Pd | Pt | |||

| Bulk concentrate | 1,185 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| Cu concentrate | 201 | 16.9 | 88.2 | 2.5 | 2.7 | 13.1 | 17.4 | 10.5 | 10.2 | 56.7 | 80.0 | 23.7 | 23.5 |

| Ni concentrate | 984 | 83.1 | 11.8 | 97.5 | 97.3 | 86.9 | 82.6 | 89.5 | 89.8 | 43.3 | 20.0 | 76.3 | 76.5 |

To see an image of Table 4: Results of copper-nickel separation (Formal Balance), please visit the following link: https://www.globenewswire.com/NewsRoom/AttachmentNg/e0b5b3b2-5b4b-4f74-afa8-ab96e8106fec

Table 5: Results of copper-nickel separation (XPS Modelled)

| Stream | Mass (%) | Assay (%) | Assay (ppm) | ||||||||||

| Cu | Ni | Co | Fe | S | MgO | SiO2 | Ag | Au | Pd | Pt | |||

| Bulk concentrate | 100.0 | % | 5.1 | 9.7 | 0.28 | 39.6 | 31.1 | 4.3 | 5.6 | 10.5 | 0.7 | 16.7 | 4.2 |

| Cu concentrate | 14.1 | % | 29.9 | 0.5 | 0.02 | 22.1 | 33.9 | 0.9 | 1.1 | 32.6 | 3.4 | 18.6 | 4.5 |

| Ni concentrate | 85.9 | % | 1.0 | 11.2 | 0.32 | 42.5 | 30.7 | 4.8 | 6.2 | 6.9 | 0.2 | 16.4 | 4.1 |

| Stream | Mass (%) | Distribution (%) | Distribution (%) | ||||||||||

| Cu | Ni | Co | Fe | S | MgO | SiO2 | Ag | Au | Pd | Pt | |||

| Bulk concentrate | 100.0 | % | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| Cu concentrate | 14.1 | % | 83.1 | 0.7 | 0.8 | 7.8 | 15.3 | 2.8 | 2.8 | 43.4 | 71.6 | 15.7 | 15.1 |

| Ni concentrate | 85.9 | % | 16.9 | 99.3 | 99.2 | 92.2 | 84.7 | 95.8 | 95.2 | 56.6 | 28.4 | 84.3 | 84.9 |

To see an image of Table 5: Results of copper-nickel separation (XPS Modelled), please visit the following link: https://www.globenewswire.com/NewsRoom/AttachmentNg/ad13c4d9-cf04-4bd2-a224-2934de86b817

Tables 4 and 5 clearly show that the majority of the recovered nickel reports to the nickel concentrate (99.3%) and the majority of the recovered copper reports to the copper concentrate (83.1%) indicating successful copper-nickel separation from the bulk concentrate. The test work also indicates the majority (84%) of platinum and palladium report to the nickel concentrate.

In summary, the XPS test work demonstrates that Eagle’s Nest ore is amenable to separate copper-nickel concentrates which show early indications of being a high-quality product with good overall recoveries and concentrate specifications. To confirm these results for a plant scale, Noront is planning to perform continuous pilot plant testing work with XPS using core samples collected from the 2020 metallurgical drilling program.

Figure 1: Massive sulfide intersection in NOT-20-001 from 107.30-143.35m depth (HQ core) is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/6ba11843-4d7b-4bab-93e3-a8d6cd992647

Quality Assurance and Quality Control (QA/QC) Program

Noront maintains a strict QA/QC protocol for all its drilling programs. Core logging and sampling is performed onsite under the supervision of geologists licensed by the Association of Professional Geoscientists of Ontario (APGO). Reference standards, field blanks, and duplicates are inserted into the sample stream at regular intervals. Once cut, drill core samples are labelled and sealed in individual bags then grouped into batches for shipping to Thunder Bay via Nakina under chain of custody documentation.

Samples are submitted to Activation Laboratories (Actlabs), an ISO-17025 certified laboratory in Thunder Bay, for sample preparation and multi-element analysis. This includes fire-assay for precious metals and total-digestion ICP-OES for base metals (exclusive of chromium which is analysed by XRF). Samples exceeding analytical upper limits are automatically run for over-limit analysis. Analytical results are sent electronically by Actlabs to a database manager at Noront whereupon the company’s internal standards, duplicates and blanks are reviewed for accuracy, precision and the presence of possible contamination. QA/QC results for each batch are reviewed by a Noront Qualified Professional prior to accepting and importing new assays into the database. All assays reported in this press release passed the Noront QA/QC program.

About Noront Resources

Noront Resources Ltd. is focused on the development of its high-grade Eagle’s Nest nickel, copper, platinum and palladium deposit and the world class chromite deposits including Blackbird, Black Thor, and Big Daddy, all of which are located in the James Bay Lowlands of Ontario in an emerging metals camp known as the Ring of Fire. www.norontresources.com

Ryan Weston, M.Sc., MBA, P.Geo, Vice-President, Exploration, Qualified Person as defined by National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“NI-43-101”), has reviewed and approved the technical information as it relates to the drilling results contained in this press release.

Mark Baker, B.Sc.Eng., M.Sc.Eng., P.Eng., Vice-President, Projects, Qualified Person as defined by National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“NI-43-101”), has reviewed and approved the technical information as it relates to the metallurgical testing results contained in this press release.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

For more information:

Technical Contact

Ryan Weston

ryan.weston@norontresources.com

(807) 285 4808 x 1

Media Contact

Janice Mandel

janice.mandel@stringcom.com

(647) 300-3853

CAUTIONARY NOTE REGARDING FORWARD-LOOKING INFORMATION

This press release includes certain “forward-looking information” within the meaning of applicable Canadian securities legislation. Forward-looking information is based on reasonable assumptions that have been made by Noront as at the date of such information and is subject to known and unknown risks, uncertainties and other factors that may cause the actual results, level of activity, performance or achievements of Noront to be materially different from those expressed or implied by such forward-looking information, including but not limited to: the impact of general business and economic conditions; that all conditions precedent to the transactions will be met; risks related to government and environmental regulation, actual results of current exploration activities, conclusions of economic evaluations (including those contained in the Feasibility Study) and changes in project parameters as plans continue to be refined; problems inherent to the marketability of base and precious metals; industry conditions, including fluctuations in the price of base and precious metals, fluctuations in interest rates; government entities interpreting existing tax legislation or enacting new tax legislation in a way which adversely affects Noront; stock market volatility; competition; risk factors disclosed in Noront’s most recent Management’s Discussion and Analysis and Annual Information Form, available electronically on SEDAR; and such other factors described or referred to elsewhere herein, including unanticipated and/or unusual events. Many such factors are beyond Noront’s ability to control or predict.

Although Noront has attempted to identify important factors that could cause actual results to differ materially, there may be other factors that cause results not to be as anticipated, estimated or intended. There can be no assurance that forward-looking information will prove to be accurate as actual results and future events could differ materially from those reliant on forward-looking information.

All of the forward-looking information given in this press release is qualified by these cautionary statements and readers are cautioned not to put undue reliance on forward-looking information due to its inherent uncertainty. Noront disclaims any intent or obligation to update any forward-looking information, whether as a result of new information, future events or results or otherwise, except as required by law. This forward-looking information should not be relied upon as representing the Company’s views as of any date subsequent to the date of this press release.