Advanced Potash Technologies Developing New Chloride-Free Potassium Fertilizers from Silicate Rocks, Interview with Ingo Wender, Founder and President and Philip Wender, President, USA Subsidiary

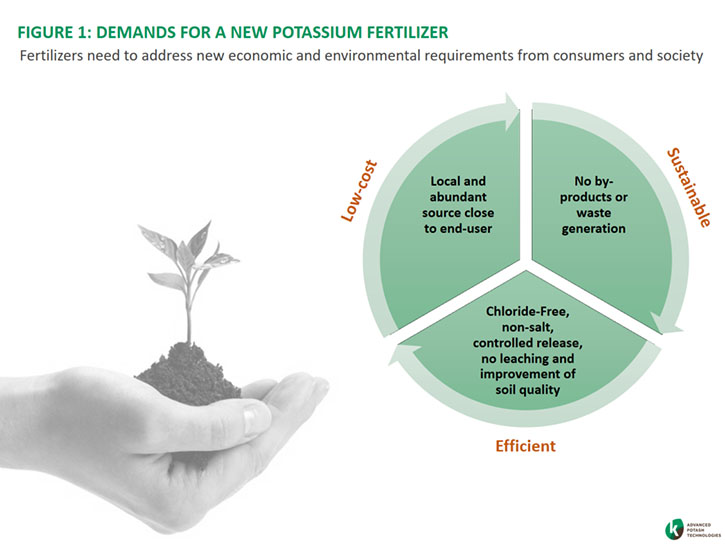

Advanced Potash Technologies is developing new chloride-free potassium fertilizers from silicate rocks with high potassium content. The company holds two patents for processing technology, owns an R&D facility in Boston, MA, and is working on larger scale pilot plant design and engineering. The company owns 6 resources in Brazil, conducts ongoing research and exploration in Brazil, Australia, and the USA and research in Africa, India and Asia. According to Ingo and Philip Wender, who are the owners of Advanced Potash Technologies, their product is competitive with MOP (KCl), the world's dominant potassium fertilizer. It has no limitations for different crops, and is locally produced, which allows Advanced Potash to cut logistics costs. As we learned from Ingo and Philip Wender, incredible population growth is expected in the coming years and there will be great demand for the fertilizers to feed all these people. The company is 100% privately owned by the founder and management team. Dr. Allen Alper:This is Dr. Allen Alper, Editor-in-Chief of Metals News, interviewing Ingo Wender, Founder and President of Advanced Potash Technologies and his son, Philip Wender, President of Advanced Potash Technologies, US. Could you give our readers/investors an overview of your company, your focus and current activities and what differentiates it from your peers?Mr. Ingo Wender:I am a mechanical engineer, but always was fascinated with geology. In 2011 we sold a major iron ore project in Brazil. We had an international group of investors including the Korean Investment Corporation and the Ontario Teachers' Pension Plan. The experience was formative for me and drove me to continue to want to operate in the minerals and mining world. Following on our iron ore success, we decided to move to another commodity and began looking at feldspar as an alternative source of potassium for fertilizer. This was driven by the fact that in spite of being an agricultural powerhouse, Brazil must import 95% of its potassium fertilizer from the northern hemisphere. Potassium is a critical element for plant growth and this dependency on foreign potassium appeared to us truly unsustainable. This is especially relevant in light of the fact that Brazil has a huge amount of potassium feldspar, the earth's main mineral source of potassium in igneous rocks. At the time, people were saying "No, that's not viable. That's too hard. The grade is too low. You cannot do it." So we put together a variety of different technologies which were already on the market while at the same time funding innovative research at MIT in order to solve this problem uniquely and economically. The result is a premium product, suitable for direct application, at costs competitive with incumbent products on the market like MOP. We understood that if you connect natural resources or ore with novel technology you can do something truly innovative. And this is how we started our potash project. We connected the resource, feldspar, with cutting edge research at MIT. Geology and materials science, running parallel, has yielded a company which is truly unique and privately owned. As the founder, I can say that it is our small and agile structure combined with technology that gives us the edge.Mr. Philip Wender:In my role as managing director, I might add two more differentiating factors on top of what Ingo has shared. First, we believe that we provide a better product, especially for sandy and tropical soils. That said, there are absolutely no limitations when it comes to different crops and soils. We can fine tune our product to suit the soil or crop which is something others cannot do.The second very big difference is that we produce locally. We can cut logistics costs, which naturally arise if you bring the product from Saskatchewan or Russia to the southern hemisphere. The two big takeaways are that it's a better, more versatile product, and it can be produced locally and is therefore much more accessible globally.

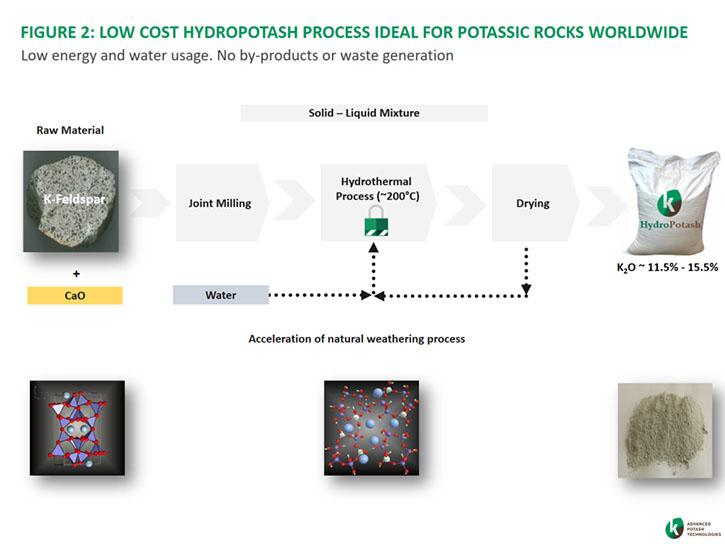

Dr. Allen Alper:This is Dr. Allen Alper, Editor-in-Chief of Metals News, interviewing Ingo Wender, Founder and President of Advanced Potash Technologies and his son, Philip Wender, President of Advanced Potash Technologies, US. Could you give our readers/investors an overview of your company, your focus and current activities and what differentiates it from your peers?Mr. Ingo Wender:I am a mechanical engineer, but always was fascinated with geology. In 2011 we sold a major iron ore project in Brazil. We had an international group of investors including the Korean Investment Corporation and the Ontario Teachers' Pension Plan. The experience was formative for me and drove me to continue to want to operate in the minerals and mining world. Following on our iron ore success, we decided to move to another commodity and began looking at feldspar as an alternative source of potassium for fertilizer. This was driven by the fact that in spite of being an agricultural powerhouse, Brazil must import 95% of its potassium fertilizer from the northern hemisphere. Potassium is a critical element for plant growth and this dependency on foreign potassium appeared to us truly unsustainable. This is especially relevant in light of the fact that Brazil has a huge amount of potassium feldspar, the earth's main mineral source of potassium in igneous rocks. At the time, people were saying "No, that's not viable. That's too hard. The grade is too low. You cannot do it." So we put together a variety of different technologies which were already on the market while at the same time funding innovative research at MIT in order to solve this problem uniquely and economically. The result is a premium product, suitable for direct application, at costs competitive with incumbent products on the market like MOP. We understood that if you connect natural resources or ore with novel technology you can do something truly innovative. And this is how we started our potash project. We connected the resource, feldspar, with cutting edge research at MIT. Geology and materials science, running parallel, has yielded a company which is truly unique and privately owned. As the founder, I can say that it is our small and agile structure combined with technology that gives us the edge.Mr. Philip Wender:In my role as managing director, I might add two more differentiating factors on top of what Ingo has shared. First, we believe that we provide a better product, especially for sandy and tropical soils. That said, there are absolutely no limitations when it comes to different crops and soils. We can fine tune our product to suit the soil or crop which is something others cannot do.The second very big difference is that we produce locally. We can cut logistics costs, which naturally arise if you bring the product from Saskatchewan or Russia to the southern hemisphere. The two big takeaways are that it's a better, more versatile product, and it can be produced locally and is therefore much more accessible globally. Dr. Allen Alper:That sounds great. Could you tell our readers/investors why your new potassium fertilizer product is ready to disrupt the market and why it is such an advancement over other ways of making fertilizer? Mr. Ingo Wender:Nitrogen, phosphate, and potassium are the most important nutrients for plants. Nitrogen fertilizer is produced from the most abundant resource we have available, air, which is everywhere. And you only need to have natural gas close by for the hydrogen. All phosphate fertilizers are produced from apatite in the earth's crust and most of the phosphate is in apatite. By contrast, MOP, which accounts for 90% for the potash fertilizer worldwide comes from very rare deposits that hold less than .01% of the K from the earth's crust and occur predominantly in the northern hemisphere.In other words, the well-established nitrogen and phosphate markets are markedly different than the potassium market when thinking about raw inputs. Turning back to potassium, feldspar has approximately 80% of the potassium in the earth's crust but there is a technological barrier because it's not available for plants. This barrier to others was our opportunity as the technology for unlocking it at low-cost is something only we know how to do.Dr. Allen Alper:Sounds very good! Could you tell our readers/investors about your proprietary HydroPotash process that you developed with MIT?Mr. Philip Wender:We wanted to be able to produce a product which is widely effective, commercially viable, and cost-effective. In order to do so, you have to make sure that your mining costs are low and that the processes following this step can result in a competitive product without introducing untenable costs.On the mining side, it is very simple. We need ore deposits that appear on surface, are very large and homogeneous, and present a grade high enough to make the process worthwhile. These sites can be mined pretty much as a quarry, which makes the entire mining operation very simple. Regarding the process, and for some historical context, towards the end of the 19th century and the beginning of the 20th century, the United States was importing 100% of their potassium fertilizer from Germany. This is why, throughout that period, several patents were filed to extract potassium from feldspar.The majority of the elements in the feldspar are very good for plants. For example, silicon is a nutrient for plants as well. The challenge, whether it is potassium or silicon, has always been to free those elements from their tight crystalline structure. Most previous attempts tried to fully extract the elements, but this was very complicated and expensive. In contrast to these former efforts, we simply disrupt the crystalline structure of feldspar sufficiently to allow roots of the plants to absorb that nutrient, and make use of the other benefits of the potassium as well. We weren't the first people to think about using feldspar, but we were the first ones to realize you only needed to disrupt the structure and then let the plant roots do the rest of the work.From the outside, the process is very straightforward. It consists of taking the feldspar, milling it down to a certain granulometry, mixing it in a specific ratio of feldspar to calcium oxide, and then combining them in a hydrothermal vessel for specific times and temperatures (Figure 2).During this process, it's important to note that there is absolutely no concentration or purification step required. Every part of the feldspar that goes into the reactor ends up going into the bag. This means you theoretically have close to 100% mass recovery.In addition, during the chemical process there are almost no waste byproducts formed, so the entire procedure is very environmentally friendly. This fact, combined with the benefit of the resource being located close to agricultural regions, means that you can distribute a green product, at economical prices, directly to farmers.

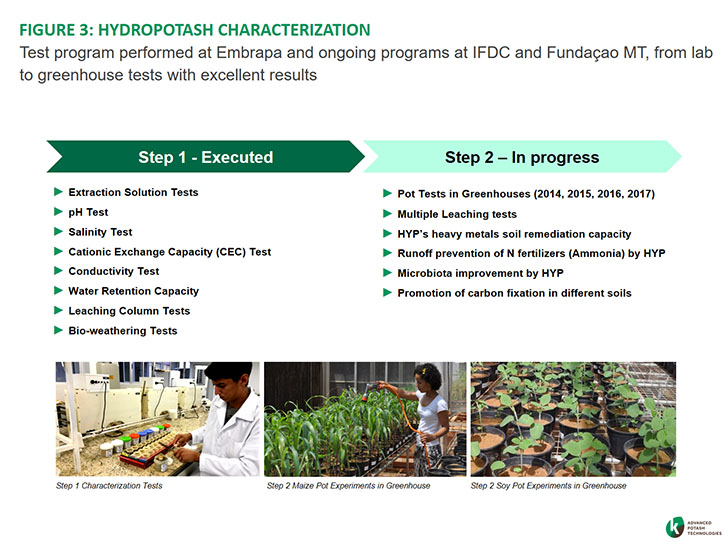

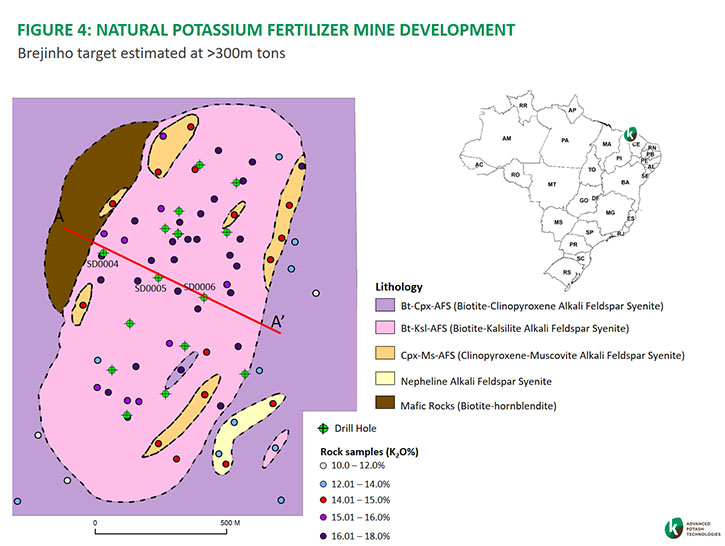

Dr. Allen Alper:That sounds great. Could you tell our readers/investors why your new potassium fertilizer product is ready to disrupt the market and why it is such an advancement over other ways of making fertilizer? Mr. Ingo Wender:Nitrogen, phosphate, and potassium are the most important nutrients for plants. Nitrogen fertilizer is produced from the most abundant resource we have available, air, which is everywhere. And you only need to have natural gas close by for the hydrogen. All phosphate fertilizers are produced from apatite in the earth's crust and most of the phosphate is in apatite. By contrast, MOP, which accounts for 90% for the potash fertilizer worldwide comes from very rare deposits that hold less than .01% of the K from the earth's crust and occur predominantly in the northern hemisphere.In other words, the well-established nitrogen and phosphate markets are markedly different than the potassium market when thinking about raw inputs. Turning back to potassium, feldspar has approximately 80% of the potassium in the earth's crust but there is a technological barrier because it's not available for plants. This barrier to others was our opportunity as the technology for unlocking it at low-cost is something only we know how to do.Dr. Allen Alper:Sounds very good! Could you tell our readers/investors about your proprietary HydroPotash process that you developed with MIT?Mr. Philip Wender:We wanted to be able to produce a product which is widely effective, commercially viable, and cost-effective. In order to do so, you have to make sure that your mining costs are low and that the processes following this step can result in a competitive product without introducing untenable costs.On the mining side, it is very simple. We need ore deposits that appear on surface, are very large and homogeneous, and present a grade high enough to make the process worthwhile. These sites can be mined pretty much as a quarry, which makes the entire mining operation very simple. Regarding the process, and for some historical context, towards the end of the 19th century and the beginning of the 20th century, the United States was importing 100% of their potassium fertilizer from Germany. This is why, throughout that period, several patents were filed to extract potassium from feldspar.The majority of the elements in the feldspar are very good for plants. For example, silicon is a nutrient for plants as well. The challenge, whether it is potassium or silicon, has always been to free those elements from their tight crystalline structure. Most previous attempts tried to fully extract the elements, but this was very complicated and expensive. In contrast to these former efforts, we simply disrupt the crystalline structure of feldspar sufficiently to allow roots of the plants to absorb that nutrient, and make use of the other benefits of the potassium as well. We weren't the first people to think about using feldspar, but we were the first ones to realize you only needed to disrupt the structure and then let the plant roots do the rest of the work.From the outside, the process is very straightforward. It consists of taking the feldspar, milling it down to a certain granulometry, mixing it in a specific ratio of feldspar to calcium oxide, and then combining them in a hydrothermal vessel for specific times and temperatures (Figure 2).During this process, it's important to note that there is absolutely no concentration or purification step required. Every part of the feldspar that goes into the reactor ends up going into the bag. This means you theoretically have close to 100% mass recovery.In addition, during the chemical process there are almost no waste byproducts formed, so the entire procedure is very environmentally friendly. This fact, combined with the benefit of the resource being located close to agricultural regions, means that you can distribute a green product, at economical prices, directly to farmers. Mr. Ingo Wender:Our approach takes into consideration sustainability and minimizing transportation, the steps needed for production, energy use and water consumption, and emissions. We wanted to be better and cheaper. Dr. Allen Alper:Sounds Excellent! Could you tell us a bit about what kind of results you have growing plants and also a bit about your facility in Boston?Mr. Philip Wender:Absolutely.I'll talk about our agronomic tests as well as our testing facility in Boston. We work with several partners on the agricultural side. Our main and first partner is Embrapa, Brazil's main agricultural development company. This state-backed research institute is known worldwide for producing very high quality agronomic work. This was the company that initiated the first bacteria research in Brazil which led to soy farming that no longer needs to consume potassium fertilizer.Embrapa is a very high quality institution. They have been our partners for over four years and during this time we have completed numerous greenhouse tests and many types of industry-standard characterization work. Now we have expanded and are working with other companies as well, such as large farming cooperatives. One example of such a partner is FMT a research organization which is owned and funded by the largest and biggest farmers in the state of Mato Grosso, Brazil. They are in the forefront of delivering new technological developments. APT owns our own greenhouse at FMT's facilities. This means we have maximum flexibility to test and explore new product capabilities and formulations. In concert, we also started working with the University of S??o Paulo, which is a worldwide leader in sugar cane research and also one of the top three agronomy research institutions worldwide. In the United States, we have been working with the International Fertilizer Development Center (IFDC) for over six months. It is a best-in-class facility for agronomic work and fertilizer development. We are focusing on rigorous characterization work in parallel with multi-soil and -crop greenhouse tests. The various greenhouse tests (Figure 3) have shown very good results for HydroPotash, very much in line with MOP. This means that we can have a similar impact on crops with a product that can be made more cheaply from feldspar-bearing rocks that can be found all over the planet. In parallel to the work on our premium product, HydroPotash, we are also rapidly developing a simpler rock-powder type product which is made from similar rock deposits. During our exhaustive geological survey of Brazil we discovered certain rare deposits which contain potassium-bearing minerals that are soluble without the need of a hydrothermal process. We call this material natural potassium fertilizer (NPF). Although this material is simpler to produce and more cost-effective than HydroPotash, the incredible scarcity of these deposits means that we cannot treat it as a long-term globally scalable solution. At Brejinho in Brazil, we are working to define a resource in a large syenite deposit where we have a core zone with over 15% K2O (Figure 4).Currently, we have the capacity to produce several tons of NPF, and we own three deposits of this source. In parallel with trial production, we are conducting 11 large-scale field tests in different parts of Brazil with a variety of partners, including FLC, one of the largest agriculture companies in Brazil. Though a large percentage of the results will come in during the spring of 2018, we're already seeing very strong performance in terms of yield and appearance.

Mr. Ingo Wender:Our approach takes into consideration sustainability and minimizing transportation, the steps needed for production, energy use and water consumption, and emissions. We wanted to be better and cheaper. Dr. Allen Alper:Sounds Excellent! Could you tell us a bit about what kind of results you have growing plants and also a bit about your facility in Boston?Mr. Philip Wender:Absolutely.I'll talk about our agronomic tests as well as our testing facility in Boston. We work with several partners on the agricultural side. Our main and first partner is Embrapa, Brazil's main agricultural development company. This state-backed research institute is known worldwide for producing very high quality agronomic work. This was the company that initiated the first bacteria research in Brazil which led to soy farming that no longer needs to consume potassium fertilizer.Embrapa is a very high quality institution. They have been our partners for over four years and during this time we have completed numerous greenhouse tests and many types of industry-standard characterization work. Now we have expanded and are working with other companies as well, such as large farming cooperatives. One example of such a partner is FMT a research organization which is owned and funded by the largest and biggest farmers in the state of Mato Grosso, Brazil. They are in the forefront of delivering new technological developments. APT owns our own greenhouse at FMT's facilities. This means we have maximum flexibility to test and explore new product capabilities and formulations. In concert, we also started working with the University of S??o Paulo, which is a worldwide leader in sugar cane research and also one of the top three agronomy research institutions worldwide. In the United States, we have been working with the International Fertilizer Development Center (IFDC) for over six months. It is a best-in-class facility for agronomic work and fertilizer development. We are focusing on rigorous characterization work in parallel with multi-soil and -crop greenhouse tests. The various greenhouse tests (Figure 3) have shown very good results for HydroPotash, very much in line with MOP. This means that we can have a similar impact on crops with a product that can be made more cheaply from feldspar-bearing rocks that can be found all over the planet. In parallel to the work on our premium product, HydroPotash, we are also rapidly developing a simpler rock-powder type product which is made from similar rock deposits. During our exhaustive geological survey of Brazil we discovered certain rare deposits which contain potassium-bearing minerals that are soluble without the need of a hydrothermal process. We call this material natural potassium fertilizer (NPF). Although this material is simpler to produce and more cost-effective than HydroPotash, the incredible scarcity of these deposits means that we cannot treat it as a long-term globally scalable solution. At Brejinho in Brazil, we are working to define a resource in a large syenite deposit where we have a core zone with over 15% K2O (Figure 4).Currently, we have the capacity to produce several tons of NPF, and we own three deposits of this source. In parallel with trial production, we are conducting 11 large-scale field tests in different parts of Brazil with a variety of partners, including FLC, one of the largest agriculture companies in Brazil. Though a large percentage of the results will come in during the spring of 2018, we're already seeing very strong performance in terms of yield and appearance.

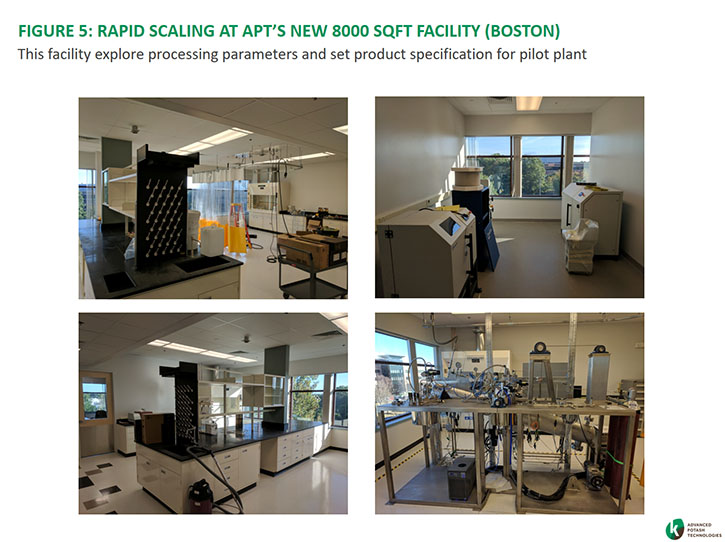

It is important to note that our product is different from what is out there. Most potassium-bearing products are salts; potassium chloride, potassium sulfate, potassium nitrate. They solubilize very quickly and they have a salinity index, which certain crops do not like. Also, in environments with significant rainfall, especially in soils which are not good at holding nutrients, a large percentage of the nutrition in these salts is lost due to leaching. In a 2002 study, the Potash and Phosphate Institute of Canada stated that potassium loss through leaching in well-drained soils in tropical areas with frequent rainfall can be over 30%.This is where we see a very big difference in our products. Our product is a controlled slow-release product. It does not all solubilize immediately. Part of the potassium is solubilized immediately so the plant can take it up during initial growth. A second portion of potassium is available for the plant and for crops throughout the growth cycle. And finally, a third part is then available for additional crop cycles and really enriches the soil. Because our product is a silicate, it has negligible salinity index, so we don't contribute at all to salinification. Another example is that our product has several phases and microstructures which drive the variety of positive properties we see for plant growth. For example, the cationic exchange capacity is extremely high. This property is highly sought after as it relates to the capacity that the soil or product has to hold on to nutrients. Mr. Ingo Wender:To put in perspective, an important question to ask is, "What is soil?" What we call soil is really just altered rock. The nutrient potassium, which is found in what we call rich soils, is really just derived from feldspar, although over a much longer time period.This ancient feldspar dissolved into the ocean and then it was recovered after it precipitated as a salt. So in fact, we are using the primary source and our process has the ability to fast track this alteration in a non-chemical process. Modern fertilizers force a plant to eat its nutrition very quickly, our product is engineered to release it slowly over the plants life. Mr. Philip Wender:In addition to these properties which plants have evolved to enjoy, the fact that this is a new and unique product means we have the ability to explore different beneficial combinations which are not possible with conventional fertilizers. We are exploring these fronts as we speak. We've had some very interesting early results. For example, given that we have a product which has no salinity, it would make sense to combine our product with beneficial bacteria and then deliver a hybrid product to crops directly. This is possible because certain strains of bacteria do not like salinity at all. We are currently working on this and also working on a partnership with a large company for this application. We're also looking into how to reduce nitrogen run off and losses by adding nitrogen into our product. Our product is highly porous with a structure similar to Zeolite, which allows you to absorb products such as nitrogen fertilizer very well and then reduce losses. Another avenue of work, which is also very interesting, is heavy metal remediation. In recent research we have found that our product is extremely good at absorbing and holding heavy metal cations. This is obviously desirable because it gives you the ability to immobilize those dangerous elements and prevent them from entering into the food chain. Rather than give up an agricultural area, countries could safely unlock lands that were once considered dangerous for growing food in. We've seen substantial interest in this topic from China though it's important to mention that this is a global challenge facing all countries in one way or another.There are a couple of other benefits our product presents. We have a high water retention capacity, which is much desired. Our product is a silicon source, not in silicates and not quartz, but the availability of silicon itself. This has been shown to be important not just because silicon itself is helpful to plants but because it also has amplifying effects for other nutrients, such as phosphorus.Dr. Allen Alper:Very impressive work! Would you like to tell us about your facilities?Mr. Philip Wender:Absolutely. Currently, we have two offices, one in Boston and one in Belo Horizonte.Our headquarters are in Boston, where our main technical R&D is being coordinated and undertaken. In parallel, our office in Brazil controls and organizes all our agronomic and geologic work.In Boston we have an integrated lab and office facility. It's roughly 8,000 square feet (Figure 5). Our research team works alongside our corporate management team to build the future of our products. Our facility has the ability to process large rocks into final fertilizer product, and characterize that product. Because we can run the full pipeline of work there, we are able to advance our research, work together with engineering partners to upscale the process, and support the growing need for more product in greenhouse testing.We have hired several talented scientists from MIT, some of whom worked on the APT-sponsored research project. Being based in the Boston area is definitely beneficial because of the technology research and the many start-up companies.

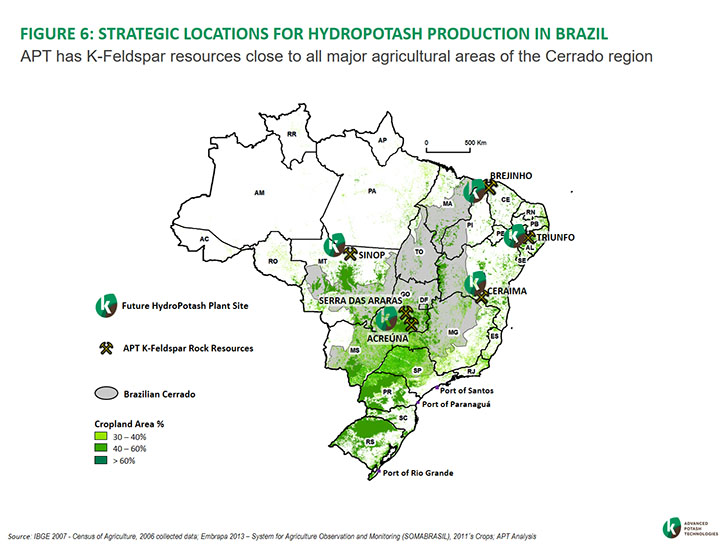

It is important to note that our product is different from what is out there. Most potassium-bearing products are salts; potassium chloride, potassium sulfate, potassium nitrate. They solubilize very quickly and they have a salinity index, which certain crops do not like. Also, in environments with significant rainfall, especially in soils which are not good at holding nutrients, a large percentage of the nutrition in these salts is lost due to leaching. In a 2002 study, the Potash and Phosphate Institute of Canada stated that potassium loss through leaching in well-drained soils in tropical areas with frequent rainfall can be over 30%.This is where we see a very big difference in our products. Our product is a controlled slow-release product. It does not all solubilize immediately. Part of the potassium is solubilized immediately so the plant can take it up during initial growth. A second portion of potassium is available for the plant and for crops throughout the growth cycle. And finally, a third part is then available for additional crop cycles and really enriches the soil. Because our product is a silicate, it has negligible salinity index, so we don't contribute at all to salinification. Another example is that our product has several phases and microstructures which drive the variety of positive properties we see for plant growth. For example, the cationic exchange capacity is extremely high. This property is highly sought after as it relates to the capacity that the soil or product has to hold on to nutrients. Mr. Ingo Wender:To put in perspective, an important question to ask is, "What is soil?" What we call soil is really just altered rock. The nutrient potassium, which is found in what we call rich soils, is really just derived from feldspar, although over a much longer time period.This ancient feldspar dissolved into the ocean and then it was recovered after it precipitated as a salt. So in fact, we are using the primary source and our process has the ability to fast track this alteration in a non-chemical process. Modern fertilizers force a plant to eat its nutrition very quickly, our product is engineered to release it slowly over the plants life. Mr. Philip Wender:In addition to these properties which plants have evolved to enjoy, the fact that this is a new and unique product means we have the ability to explore different beneficial combinations which are not possible with conventional fertilizers. We are exploring these fronts as we speak. We've had some very interesting early results. For example, given that we have a product which has no salinity, it would make sense to combine our product with beneficial bacteria and then deliver a hybrid product to crops directly. This is possible because certain strains of bacteria do not like salinity at all. We are currently working on this and also working on a partnership with a large company for this application. We're also looking into how to reduce nitrogen run off and losses by adding nitrogen into our product. Our product is highly porous with a structure similar to Zeolite, which allows you to absorb products such as nitrogen fertilizer very well and then reduce losses. Another avenue of work, which is also very interesting, is heavy metal remediation. In recent research we have found that our product is extremely good at absorbing and holding heavy metal cations. This is obviously desirable because it gives you the ability to immobilize those dangerous elements and prevent them from entering into the food chain. Rather than give up an agricultural area, countries could safely unlock lands that were once considered dangerous for growing food in. We've seen substantial interest in this topic from China though it's important to mention that this is a global challenge facing all countries in one way or another.There are a couple of other benefits our product presents. We have a high water retention capacity, which is much desired. Our product is a silicon source, not in silicates and not quartz, but the availability of silicon itself. This has been shown to be important not just because silicon itself is helpful to plants but because it also has amplifying effects for other nutrients, such as phosphorus.Dr. Allen Alper:Very impressive work! Would you like to tell us about your facilities?Mr. Philip Wender:Absolutely. Currently, we have two offices, one in Boston and one in Belo Horizonte.Our headquarters are in Boston, where our main technical R&D is being coordinated and undertaken. In parallel, our office in Brazil controls and organizes all our agronomic and geologic work.In Boston we have an integrated lab and office facility. It's roughly 8,000 square feet (Figure 5). Our research team works alongside our corporate management team to build the future of our products. Our facility has the ability to process large rocks into final fertilizer product, and characterize that product. Because we can run the full pipeline of work there, we are able to advance our research, work together with engineering partners to upscale the process, and support the growing need for more product in greenhouse testing.We have hired several talented scientists from MIT, some of whom worked on the APT-sponsored research project. Being based in the Boston area is definitely beneficial because of the technology research and the many start-up companies. Dr. Allen Alper:Well that sounds very good. What are the primary reasons our high-net-worth readers/investors should consider investing in your company?Mr. Philip Wender:The main reason is because this is a product that can disrupt an entire industry. The potassium business is something that will be there forever because people need to eat and that will never change. You have incredible population growth as well, which will inexorably drive the further need for better food yields. It is key to realize that fertilizers will and must play a key part of the solution to this challenge. There are many other intelligent agricultural technologies being developed right now, but few if any have as much impact on yields as good fertilization. We aim to provide a higher quality and locally produced product for farmers that are currently consuming potassium as well as expand to helping those that have no access to this nutrient at the moment. Finally, this opportunity is global because we are mining a resource which is available in every single country. Mr. Ingo Wender:Also importantly, the market is there. We have the world population, a huge market for potash fertilizer. This market is growing at a very fast pace. In 2050 we are projected to have close to 10 billion people on earth. Currently Africa is not a market for potash fertilizer. The consumption of potash fertilizer in Africa is very small. Fewer than 500,000 pounds of product are sold in Africa yearly. While the potential would be more than ten times that. Just think of the positive impact more efficient agricultural production would have on Africa. Although Africa is a great example of the potential new markets available, our business model in the near-term is focusing on Brazil, where we have six resources that have great potential to be mines (Figure 6). Brazil is our real beachhead market and the first test of how our product can do at scale. From there, we expect to move quickly to North America.

Dr. Allen Alper:Well that sounds very good. What are the primary reasons our high-net-worth readers/investors should consider investing in your company?Mr. Philip Wender:The main reason is because this is a product that can disrupt an entire industry. The potassium business is something that will be there forever because people need to eat and that will never change. You have incredible population growth as well, which will inexorably drive the further need for better food yields. It is key to realize that fertilizers will and must play a key part of the solution to this challenge. There are many other intelligent agricultural technologies being developed right now, but few if any have as much impact on yields as good fertilization. We aim to provide a higher quality and locally produced product for farmers that are currently consuming potassium as well as expand to helping those that have no access to this nutrient at the moment. Finally, this opportunity is global because we are mining a resource which is available in every single country. Mr. Ingo Wender:Also importantly, the market is there. We have the world population, a huge market for potash fertilizer. This market is growing at a very fast pace. In 2050 we are projected to have close to 10 billion people on earth. Currently Africa is not a market for potash fertilizer. The consumption of potash fertilizer in Africa is very small. Fewer than 500,000 pounds of product are sold in Africa yearly. While the potential would be more than ten times that. Just think of the positive impact more efficient agricultural production would have on Africa. Although Africa is a great example of the potential new markets available, our business model in the near-term is focusing on Brazil, where we have six resources that have great potential to be mines (Figure 6). Brazil is our real beachhead market and the first test of how our product can do at scale. From there, we expect to move quickly to North America. We have applied for two exploration licenses in the US and there are more to come. There is a huge market in the US for sulfate of potash (SOP), an alternative potassium fertilizer that does not contain chloride, but it's still a salt. This product is often considered a premium product and comes with a significant price premium.Our product is much more price competitive than SOP and it is important to note that its results are also better. So there is a market in the US for our product - namely organics and chloride-sensitive crops. In Brazil our product can be a substitute for MOP because the Brazilian soil performs better without chloride. Meanwhile, in Africa, we can access a completely untouched market simply because much of the agricultural land is landlocked and the ports are inefficient.In these three cases there are indeed different market strategies but this is just as much a reflection of the adaptable nature of our product as it is the diversity of challenges facing farmers around the world. Everything seems to be in place for our business. We are working on many fronts, with excellent people. The time is right for us.Mr. Philip Wender:We are de-risking the three important areas of engineering, agronomy, and marketing. We are working currently with l'??cole Polytechnique of Montr?(C)al (EPM), who are doing all the kinetic and thermodynamic calculations for us to help us optimize the process to a point where it is as cheap as possible. In addition to the efforts at EPM, we are engaging with one of the leading engineering companies in the world to design pilot and commercial-scale plants. Our process is very simple. It is a straightforward, low temperature hydrothermal process, which has precedent in many other processes. We feel much of the risk of the engineering/technology part is taken care of. We are working with the best agronomy partners in the world. From their independent greenhouse results, there is no doubt that this is a high quality product. To limit commercial risk, we are already working and partnering with very large institutions and farming groups, which have great interest because they understand the limitations of the existing product. The openness to work with us that we have seen is very encouraging. To be honest, I think we were not expecting the amount of market pull we have been seeing in the last year.Mr. Ingo Wender: The Company is fully privately held and owned. The reason we believe that's very important is because it gives the group full autonomy and control to focus on the important things. Given our experience, I think this is one of the reasons why we have been able to accomplish so much in a short period of time. All of the directors of the company have a lot of experience in the fields of business, finance, technology, and natural resources. These individuals have worked at high levels in their respective industries. In closing, we are looking for investors who share our long term view of growing a transformational business. It's important to have a return on investment. We want a partner who has a long term world view. This year we are having a booth at the PDAC mining conference in Toronto in March.We plan to introduce our company to the mining community and interact with potential investors. Dr. Allen Alper:Well that sounds excellent. Sounds like you have a great team, great partners and you have excellent technology and properties and you're doing very well. So I think those are very compelling reasons for our high-net-worth readers/investors to consider investing in your company.

We have applied for two exploration licenses in the US and there are more to come. There is a huge market in the US for sulfate of potash (SOP), an alternative potassium fertilizer that does not contain chloride, but it's still a salt. This product is often considered a premium product and comes with a significant price premium.Our product is much more price competitive than SOP and it is important to note that its results are also better. So there is a market in the US for our product - namely organics and chloride-sensitive crops. In Brazil our product can be a substitute for MOP because the Brazilian soil performs better without chloride. Meanwhile, in Africa, we can access a completely untouched market simply because much of the agricultural land is landlocked and the ports are inefficient.In these three cases there are indeed different market strategies but this is just as much a reflection of the adaptable nature of our product as it is the diversity of challenges facing farmers around the world. Everything seems to be in place for our business. We are working on many fronts, with excellent people. The time is right for us.Mr. Philip Wender:We are de-risking the three important areas of engineering, agronomy, and marketing. We are working currently with l'??cole Polytechnique of Montr?(C)al (EPM), who are doing all the kinetic and thermodynamic calculations for us to help us optimize the process to a point where it is as cheap as possible. In addition to the efforts at EPM, we are engaging with one of the leading engineering companies in the world to design pilot and commercial-scale plants. Our process is very simple. It is a straightforward, low temperature hydrothermal process, which has precedent in many other processes. We feel much of the risk of the engineering/technology part is taken care of. We are working with the best agronomy partners in the world. From their independent greenhouse results, there is no doubt that this is a high quality product. To limit commercial risk, we are already working and partnering with very large institutions and farming groups, which have great interest because they understand the limitations of the existing product. The openness to work with us that we have seen is very encouraging. To be honest, I think we were not expecting the amount of market pull we have been seeing in the last year.Mr. Ingo Wender: The Company is fully privately held and owned. The reason we believe that's very important is because it gives the group full autonomy and control to focus on the important things. Given our experience, I think this is one of the reasons why we have been able to accomplish so much in a short period of time. All of the directors of the company have a lot of experience in the fields of business, finance, technology, and natural resources. These individuals have worked at high levels in their respective industries. In closing, we are looking for investors who share our long term view of growing a transformational business. It's important to have a return on investment. We want a partner who has a long term world view. This year we are having a booth at the PDAC mining conference in Toronto in March.We plan to introduce our company to the mining community and interact with potential investors. Dr. Allen Alper:Well that sounds excellent. Sounds like you have a great team, great partners and you have excellent technology and properties and you're doing very well. So I think those are very compelling reasons for our high-net-worth readers/investors to consider investing in your company.