Synova Launches Automated Cutter

RAPAPORT... A technology provider part-owned by De Beers has unveiled anautomated cutting machine that, it claims, will significantly speed up diamondmanufacturing and reduce costs. Synova's DaVinci system is the market's first automated instrument that can produce all 57 facets of a round brilliant diamond in one process, the Swiss company saidThursday. The user only needs to perform one final polishing stage to finish the stone.

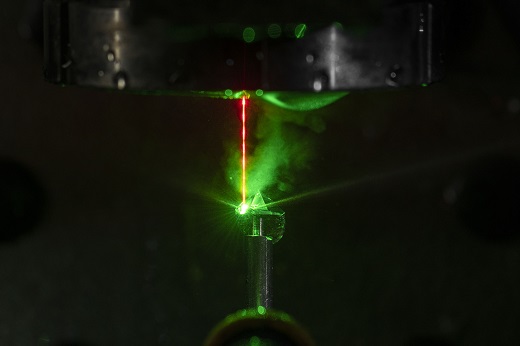

RAPAPORT... A technology provider part-owned by De Beers has unveiled anautomated cutting machine that, it claims, will significantly speed up diamondmanufacturing and reduce costs. Synova's DaVinci system is the market's first automated instrument that can produce all 57 facets of a round brilliant diamond in one process, the Swiss company saidThursday. The user only needs to perform one final polishing stage to finish the stone. "Several cost-,skill- and labor-intensive steps in the polishing phase, such as crown andpavilion blocking, girdle bruting or recurrent quality checks, become redundant,"noted Bernold Richerzhagen, Synova's founder and CEO. The machine, currently intended for rough stones from 0.50 to 10 carats, gives manufacturers increased flexibility to adapt their production levels tobusiness needs, such as seasonal demand, Synova explained.It also gives better symmetry and a higher and more predictable polished yield, and uses water-jet technology to reduce the risk of diamond-cracking, the company asserted. It's based on its existing DCS 50 cutting machine. De Beersbought a 33% stake in Synova in 2015, pledging to work with the company todevelop a fully automated cutting-and-shaping solution. The miner has made diamondsavailable for some of the machine testing.Images: The DaVinci machine. (Synova)

"Several cost-,skill- and labor-intensive steps in the polishing phase, such as crown andpavilion blocking, girdle bruting or recurrent quality checks, become redundant,"noted Bernold Richerzhagen, Synova's founder and CEO. The machine, currently intended for rough stones from 0.50 to 10 carats, gives manufacturers increased flexibility to adapt their production levels tobusiness needs, such as seasonal demand, Synova explained.It also gives better symmetry and a higher and more predictable polished yield, and uses water-jet technology to reduce the risk of diamond-cracking, the company asserted. It's based on its existing DCS 50 cutting machine. De Beersbought a 33% stake in Synova in 2015, pledging to work with the company todevelop a fully automated cutting-and-shaping solution. The miner has made diamondsavailable for some of the machine testing.Images: The DaVinci machine. (Synova)