US $2 Trillion Infrastructure Plan Will Require Mega Metals / Commodities / Metals & Mining

TheWhite House and Congress finally agreed to put their significant differencesaside and work together on something constructive, no pun intended.

TheWhite House and Congress finally agreed to put their significant differencesaside and work together on something constructive, no pun intended.

OnWednesday it was announced that President Trump and Democratic congressionalleaders plan to spend $2 trillion on US roads, bridges, powergrids, water and broadband infrastructure -bricks and mortar priorities that are sorely underfunded in both the UnitedStates and Canada.

Formore on this, read our The global infrastructure deficit: the road not yet taken

“Wejust had a very productive meeting with the president of the United States,”House of Representatives Speaker Nancy Polosi said during a press scrum,adding: “We did come to one agreement: That the agreement would be big andbold.”

TheDemocrats’ House leader Chuck Schumer was equally optimistic, per Reuters:

“Weagreed on a number, which was very, very good - $2 trillion for infrastructure.Originally we had started with a lower - even the president was eager to pushit up to $2 trillion,” Schumer said.

Trumpcampaigned on a pledge for fix America’s crumbling towns, cities, freeways,ports etc., but a $1.5 trillion White House infrastructure proposal last yeardidn’t go anywhere. The plan called for $200 billion in federal funds thatwould require a 4-1 match from state and local governments.

Theproposed legislation reportedly faced hurdles in Congress because it didn’toffer enough federal funding for Democrats, nor did it address how the programwould be paid for. A later $1 trillion proposal by House Democrats also failedto get any traction.

Thefact that the Dems and the GOP have shown bipartisanship in a government thatup to now has been as divisive asthey come, is good news. We’ll leave thethorny subject of whether the legislation actually passes, to the politicalgurus. Let’s presume it does. What would it mean for mined metals? This articletakes a stab at that question.

$2T shortfall

Spendingon infrastructure, also known as “blacktop politics”, is a common way forpoliticians to earn votes in an election cycle, but for the United States theissue transcends politics because the need is so dire.

Accordingto the American Society of Civil Engineers (ASCE), the US needs to spend $4.6trillion between 2016 and 2024 in order to upgrade all its infrastructure to anacceptable standard. But only $2.6T has been earmarked, leaving a funding gapof $2 trillion. US lawmakers must have been reading the 2017 Infrastructure Report Card, put out by the ASCE every four years, with its $2Tshortfall figure.

Wesee and hear about the implications of infrastructure neglect almost every dayin the news.

Infrastructure failures

Likelythe most impactful, in terms of the potential for death and destruction, areblackouts or brownouts that happen when electrical grids fail. In the UnitedStates, the grids are particularly vulnerable to hurricanes, floods andscorching-hot weather. They must be sturdy enough to withstand naturaldisasters that are becoming all too frequent due to climate change.

Butthe US energy system, comprising 640,000 miles of high-voltage transmissionlines split into three grids by region, is at full capacity. Most of it wasbuilt in the 1950s and 60s and has a 50-year life expectancy.

Halfof the nine worst power outages in US history were storm-related. In 2012 a line of fast-moving windsand thunderstorms called a “derecho” moved across the US Midwest, causing 4million people across 11 states to lose power; some were in the dark for 10days. This was just a warmup though to Sandy, a massive hurricane that impacted24 states the same year. The storm drenched New York, flooding streets andclosing subway lines, and cutting power to some New Yorkers for up to twoweeks. The damage to New York City was $18 billion, more than the damage tallyfor all the other states combined.

Affectingless people but more dramatic, are bridge failures. There are few accidents -except maybe a plane crash or a passenger train derailment - that strikes asmuch fear into the traveling public, as a major bridge collapsing as you driveover it. In 2007 it happened in Minneapolis. Investigators said support plates that were half as thick as they should becaused the I-35 W bridge to fall down,killing 13 people.

Thenthere’s the annoying. Fitting into this category are overcrowded airports, subways,buses, and schools. All are problems that could be alleviated by building moreinfrastructure. Nobody has likely died from a watermain break but theseincidents always draw attention to how old these pipes are.

OnJuly 29, 2014, a major watermain in Los Angeles sprung a leak, causing 20million gallons to spill onto the UCLA campus. The flood waterlogged andstranded hundreds of vehicles. It was discovered that the problem was at thejuncture of a 93-year-old and 53-year-old water pipe under Sunset Boulevard.

Infrastructure metals & uses

Infrastructureis the physical systems – the roads, power transmission lines and towers,airports, dams, buses, subways, railways, ports, bridges, power plants, waterdelivery systems, hospitals, sewage treatment, etc. – that are the buildingblocks, the Lego pieces, which fuel a country’s, city’s or community’seconomic, social and financial development.

Economicgrowth necessitates building more infrastructure to meet increasing demands onpower, heat, water, roads and the like. As populations grow, they need morehouses, hospitals, subway lines, roads, recreational facilities, sportsstadiums.

Thereis an undeniable connection between a country’s competitiveness and itsinfrastructure, yet both Canada and the US are facing significantinfrastructure deficits, meaning the money that is being allocated for upgradesto water lines, sewers, bridges, roads, dams, power plants, public buildings,etc., isn’t enough to cover maintenance let alone replacement costs.

Theamount of pipe rehabilitation, the number of dams that need to be upgraded, newports, airports, bridges, power plants etc., will require billions of tonnes ofraw materials. We’re talking iron ore, steel, zinc, manganese, vanadium andcopper, just to name a few key metals.

Let’stake a closer look at some key infrastructure metals, and their uses ininfrastructure.

Asidefrom iron ore, manganese is the most essential mineral in the production ofsteel. You can’t produce steel without adding 10 to 20 pounds of manganese pertonne of iron ore, making manganese the fourth most traded metal commodity.

Canadaand the United States have numerous and vast iron ore deposits, yet neithercountry produces manganese.

Steel

Buildingnew North American infrastructure would obviously take a lot of steel. It’shard to say how much, but consider these facts: The Hoover Dam on theArizona-Nevada state line used 45 million pound of reinforced steel, 88 millionpounds of plate steel and outlet pipes, 6.7 million pounds of pipe andfittings, and 4.4 million yards of concrete.

Accordingto the American Society of Civil Engineers, by 2025 70% of US dams will be over50 years old and past their life expectancies. The cost to rehabilitate them?$64 billion. It would cost American taxpayers one-third of that just to repairthe most hazardous dams.

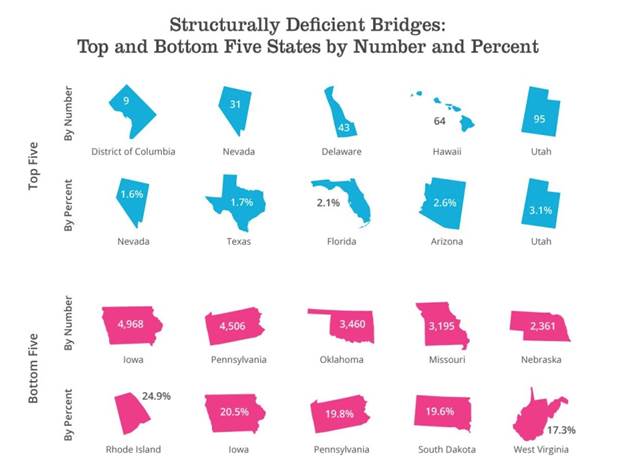

Bridgesare in equally bad shape. The United States has 614,387 bridges. Nearly four in10 are over 50 years of age. On average 188 million trips are made across astructurally deficient bridge every day! The engineering society (ASCE) tellsus that the backlog of bridge rehabilitation is valued at $123 billion.

Themost common raw materials found in new modern bridges are steel, concrete,stone and asphalt. Steel is often used in the bridge superstructure forexpansion joints, beams, bearings, floor beams, girders, reinforcing bars inconcrete, traffic barriers and trusses. It is used in the substructure for thereinforcing bars in concrete, armoring for expansion joints, anchor bolts, etc.It is also used for piles to support the abutments and piers.

Toget an idea how much steel is required to fix America’s broken-down bridges,consider the raw materials that went into just one new bridge, the $24-million SundialBridge in California, completed in 2004:

In addition to being a functional work ofart, the Sundial Bridge is a technical marvel as well. The cable-stayedstructure has an inclined, 217 foot pylon constructed of 580 tons of steel. Thedeck is made up of 200 tons of glass and granite and is supported by more than4,300 feet of cable. The structure is stabilized by a steel truss, and rests ona foundation of more than 115 tons of steel and 1,900 cubic yards of concrete.

Thefamous Golden Gate Bridge contains about 88,000 tons of steel, and 80,000 milesof wire inside each of the two steel cables. That’s enough wire to go aroundthe world three times.

Zincis mostly used in steel fabrication to prevent rusting; it is an essentialcomponent of galvanized steel bridges.

Rare earths

Rareearths are used in a variety of industrial applications. Updating Internetspeeds to 5G using fibre-optics requires erbium for the fiber. Computers thatwill go into new schools and public buildings contain europium. REEs are usedin metallurgy as an alloying agent to desulfurize steels, as a nodularisingagent in ductile iron, and as alloying agents to improve the properties ofmagnesium, aluminium and titanium alloys.

Copper

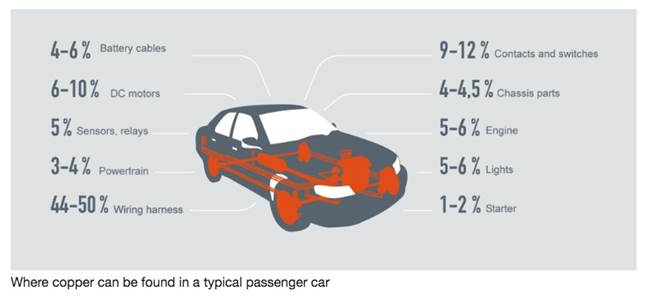

Copperis used for electrical applications because it is an excellent conductor ofelectricity. That, combined with its corrosion resistance, ductility,malleability, and ability to work in a range of electrical networks, makes itideal for wiring. Among electrical devices that use copper are computers,televisions, circuit boards, semiconductors, microwaves and fire preventionsprinkler systems.

Intelecommunications, copper is used in wiring for local area networks (LAN),modems and routers. The construction industry would not exist without copper -it is used in both wiring and plumbing. The red metal is also used for potablewater and heating systems due to its ability to resist the growth ofwater-borne organisms, as well as its resistance to heat corrosion.

Considerthe amount of copper needed to upgrade rail networks. The ASCE divides the railinfrastructure deficit into freight rail and passenger rail.

TheFederal Railroad Administration estimates that, of the $6.9 billion needed tomaintain, modernize and expand freight rail capacity, 2017-22, railroads onlyhave $1.6 billion. Scary when you consider how the dearth of pipeline capacityin Canada is forcing producers to ship their product by rail.

InMarch 2018 the crude-by-rail exports to the United States hit athree-year high of 170,000 barrels a day.That’s not too impressive until you consider the accidents that have occurredshipping crude oil by rail. How about the Lac Megantic trail derailment inQuebec that killed 24 people and spilled 1.5 million gallons of crude? Or theMount Carbon trail derailment in 2015, where 19 tank cars of crude oil went offthe tracks in West Virginia? The large oil spill caught fire, resulting inseveral large, violent fireball eruptions that destroyed one home and forcedthe evacuation of hundreds of families. Each car was carrying 30,000 gallons ofcrude oil.

Forpassenger rail, the repair backlog is $28 billion.

Howmuch metal will be required to upgrade US freight and passenger rail? Again wecan only estimate but consider the amount of copper it takes to build ahigh-speed train network: 10 tonnes per kilometer of track. Powerful electriclocomotives contain over eight tonnes of copper, according to the Copper Alliance.

Publictransit is lacking in the US compared to Canada and Europe. New subway andlight-rail systems are badly needed to get motorists out of their cars. Buseswill also be in high demand.

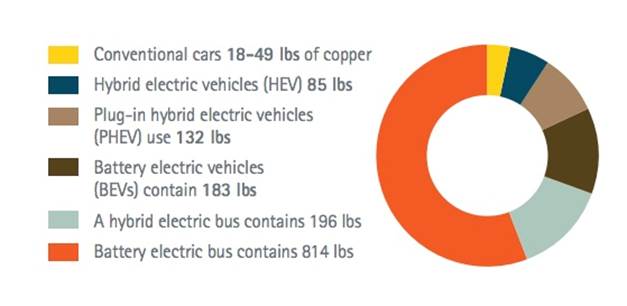

Likely,the buses of the future will be electric. EVs contain about four times as muchcopper as regular vehicles. A hybrid electric bus has 196 pounds, and 814pounds of copper go into a hybrid-electric bus, mostly the battery. The CopperAlliance states that the largest EV maker, China’s BYD, used an estimated 26million pounds of copper in 2016.

Military infrastructure

Sofar we have only talked about civilian infrastructure needs; there’s also theneeds of the US Military. The $2 trillion infrastructure deficit doesn’tinclude money that needs to be spent on military barracks, storage buildings,roads, lighting, etc.

Consideringwe are in the beginning stages of a Cold War between the US, Russia andChina, it’s the wrong time to be under-funding the military. Andanother reason why the United States government needs to take a hard look atthe metals it lacks. The US Military is number one despite having virtually norare earths of its own (other than one light rare earths mine in California)that go into a plethora of defense applications, no production of manganesenecessary for steel, no domestic vanadium or titanium used in fighter aircraft,and 100%-reliant on imports for it’s metallurgical-grade bauxite used foraluminum.

President Trump just pilfered $3.6 billion from thePentagon’s funding and put it towards his border wall, despite the fact that the US Air Force is in desperateneed of funding for bases hammered by recent bad weather, and just generaldeterioration.

TheAir Force needs $5 billion to rebuild bases in Florida and Nebraska. HurricaneMichael destroyed most of the Tyndall base when it slammed into the FloridaPanhandle in October, while the base in Offutt was inundated by an overflowingMissouri River that damaged nearly 80 buildings.

An article by Defense One uncovers a startling backlog of deferred maintenance ofmilitary infrastructure that extends to 2047! This is due to chronicunderfunding since 2012. It’s hard to believe the Department of Defense has aproblem funding anything; its nearly $1 trillion allowance is the largest itemin the federal budget behind Social Security. The DoD’s base budget for 2019-20 is $576 billion.

Yetaccording to Defense One, combined spending on military construction and familyhousing is nearly half what it was in 2012, $14.6 billion, versus an annualaverage of $8.2 billion from 2015 to 2018.

ThePentagon rates 23% of its infrastructure is in poor condition and another 9% isfailing. Some of it is in such rough shape, it’s not worth saving.

Conclusion

The$2 trillion that the White House is planning to spend on infrastructure has twoaspects to it. One is finding the money. There’s plenty of money in the budget,but most of it goes to Social Security and defense. The close to a trillion dollars a year the AmericanSociety of Civil Engineers says it needs for the next five years is there, it justisn’t allocated. To lawmakers there must be other priorities.

Thesecond problem relates to how we source the materials needed for rebuildingAmerican infrastructure. The amount of pipe rehabilitation, the number of damsthat need to be upgraded, new ports, airports, bridges, power plants etc., willrequire billions of tonnes of raw materials. We’re talking iron ore, steel,zinc, manganese, vanadium and copper, just to name a few key metals.

Someof these metals are unavailable in the States or Canada. North America has somedeposits, but no mines. So we import them.

Wethink we can just get the metals needed for these huge infrastructurebuild-outs from places like China, Russia, South Africa, the DRC and Gabon, butthese countries aren’t reliable and in the case of the first two, they haveshown they are not friendly to the West.

Mostpeople don’t know it, but Canada and the US are dependent on foreign countriesfor a number of critical metals. Without a reliable supply chain, a countrymust depend on outsiders. This gives foreign suppliers incredible leverage overNorth Americans. There is always the possibility of slowed flows or bans onstrategic materials, due to politics or trade disputes – a perfect example isSaudi Arabia’s threat to slow or stop oil production if sanctioned over theKhoshoggi affair, another current example is the ongoing trade dispute withChina.

TheUS is dependent on South Africa, the politically unstable Democratic Republic of Congo (DRC) and an increasingly unreliable and aggressive China for over halfof its supply of what it considers strategic or critical minerals.

Rareearths, manganese and vanadium are three examples of critical metals needed forthe massive infrastructure build-out the US is talking about, in that $2trillion bill it’s talking about passing. America doesn’t mine any of them. (wecan’t really count the Mountain Pass rare earths mine in California because theconcentrates are shipped to China for refining into oxides)

Themajority of the metals needed, as we’ve discussed, are base metals like ironore, zinc and copper. The United States is not a major producer of any of thesemetals. In fact, there is no way the US will be able to correct itsinfrastructure deficit through domestic mining; a large percentage will have tobe imported.

Asthe infrastructure roll-out begins (if the infrastructure bill is passed... )we should also remind ourselves that, while improving public infrastructure isa good thing in terms of safety and productivity, it is yet another sign ofresource gluttony.

Aswe wrote about in We are the lemmings, every yearwe are depleting our resources faster and faster.

Forexample, China’s Belt and Road Initiative (BRI) is expected to push demand forcopper to 6.5 million tonnes by 2027, an increase of 22% compared to 2017,according to the International Copper Association. Imagine how much steel, iron ore, concrete, etc., Beltand Road is going to consume? It boggles the mind.

Inthe absence of change, we can only observe, and bet on trends. As metal marketsobservers, we know that coming deficits in copper and zinc, to name twoinfrastructure metals, are about to meet a tsunami of demand, as Belt and Roadand US/ Global infrastructure spends seriously ramp up. Where are they going tofind the metal? Who knows, but we are sure it’s going to become dearer.

By Richard (Rick) Mills

If you're interested in learning more about the junior resource and bio-med sectors please come and visit us at www.aheadoftheherd.com

Site membership is free. No credit card or personal information is asked for.

Richard is host of Aheadoftheherd.com and invests in the junior resource sector.

His articles have been published on over 400 websites, including: Wall Street Journal, Market Oracle,USAToday, National Post, Stockhouse, Lewrockwell, Pinnacledigest, Uranium Miner, Beforeitsnews, SeekingAlpha, MontrealGazette, Casey Research, 24hgold, Vancouver Sun, CBSnews, SilverBearCafe, Infomine, Huffington Post, Mineweb, 321Gold, Kitco, Gold-Eagle, The Gold/Energy Reports, Calgary Herald, Resource Investor, Mining.com, Forbes, FNArena, Uraniumseek, Financial Sense, Goldseek, Dallasnews, Vantagewire, Resourceclips and the Association of Mining Analysts.

Copyright © 2019 Richard (Rick) Mills - All Rights Reserved

Legal Notice / Disclaimer: This document is not and should not be construed as an offer to sell or the solicitation of an offer to purchase or subscribe for any investment. Richard Mills has based this document on information obtained from sources he believes to be reliable but which has not been independently verified; Richard Mills makes no guarantee, representation or warranty and accepts no responsibility or liability as to its accuracy or completeness. Expressions of opinion are those of Richard Mills only and are subject to change without notice. Richard Mills assumes no warranty, liability or guarantee for the current relevance, correctness or completeness of any information provided within this Report and will not be held liable for the consequence of reliance upon any opinion or statement contained herein or any omission. Furthermore, I, Richard Mills, assume no liability for any direct or indirect loss or damage or, in particular, for lost profit, which you may incur as a result of the use and existence of the information provided within this Report.

© 2005-2019 http://www.MarketOracle.co.uk - The Market Oracle is a FREE Daily Financial Markets Analysis & Forecasting online publication.